EUROSTER 12 User manual

EUROSTER 12 – INSTALLATION AND OPERATION MANUAL 1

EUROSTER 12

Universal controller for heating system

MANUFACTURER: P.H.P.U. AS, Chumiętki 4, 63-840 Krobia, Poland

In order to take full advantage of the controller capabilities and ensure proper operation of a

heating system, please read this user manual carefully.

Manual version: 29.03.2016

1. APPLICATION

EUROSTER 12 is a universal controller designed to control a heating system.

It is equipped with three independently operating control outputs (relays). Based on the

measured temperatures or time, the controller switches on and off a relay for each output.

Flexible arrangement enables adaptation of the controller to the needs of the majority of

systems. Each of the controller outputs may be set up to interact with:

central heating circulation pump

domestic hot water tank feeding pump

domestic hot water zone circulation pump

floor heating pump

blower (no speed adjustment)

any device (thermostat mode, time-based operation mode).

All parameters are shown on a readable graphical display and the device is very easy to

control with a knob and a button.

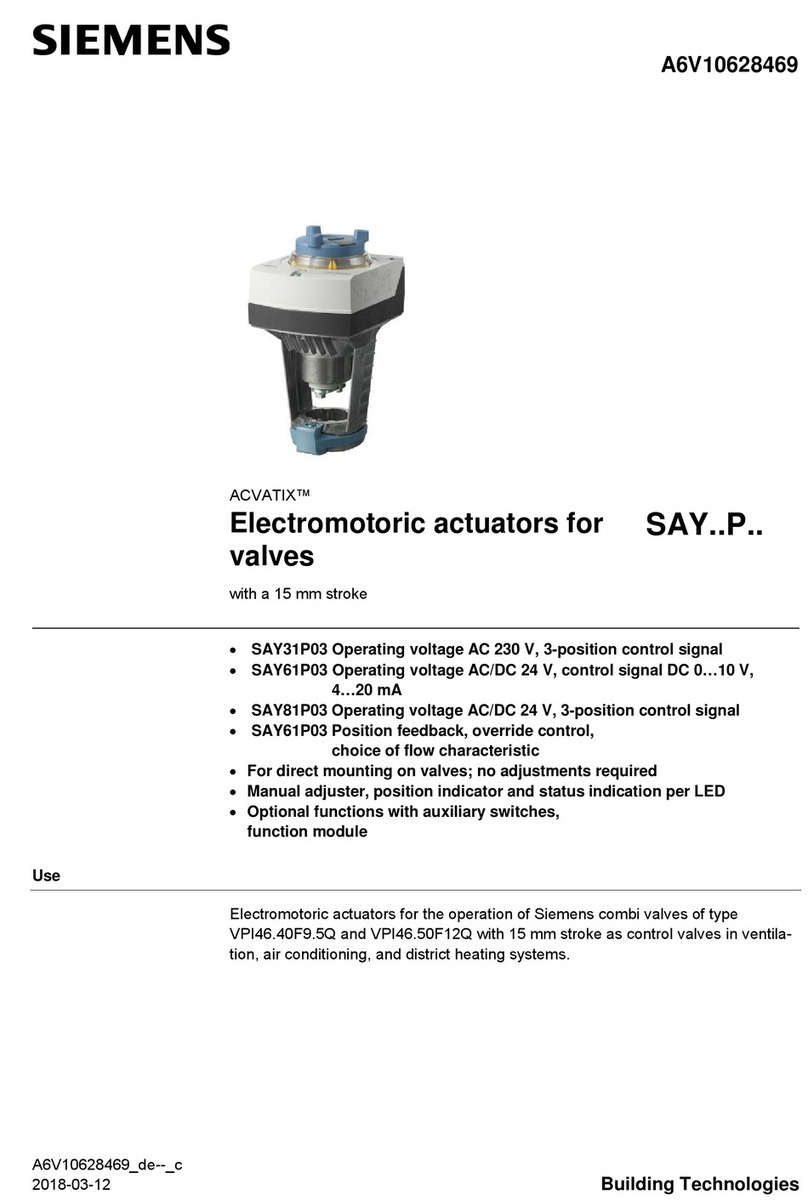

Example of a CH pump, floor heating pump (thermostatic mixer) and DHW tank feeding pump

control system

EUROSTER 12 – INSTALLATION AND OPERATION MANUAL 2

1. Feeding temperature sensor

2. CH zone pump

3. CH zone temperature sensor

4. Floor heating pump (thermostatic

mixer)

5. Floor heating zone temperature

sensor

6. DHW tank feeding pump

7. DHW tank temperature sensor

2. BASIC FUNCTIONS OF THE CONTROLLER

weekly operating schedules independent for each output

configurable DHW priority

overheating protection for the zones

alarm indication

SUMMER/WINTER operation mode

frost protection mode for pump operation

possibility to turn off any unused output

Anti-Stop function – protection of pumps against seizure

possibility to test each output independently

readable, graphical, backlit LCD

three relay outputs

set of temperature sensors

surface mounting

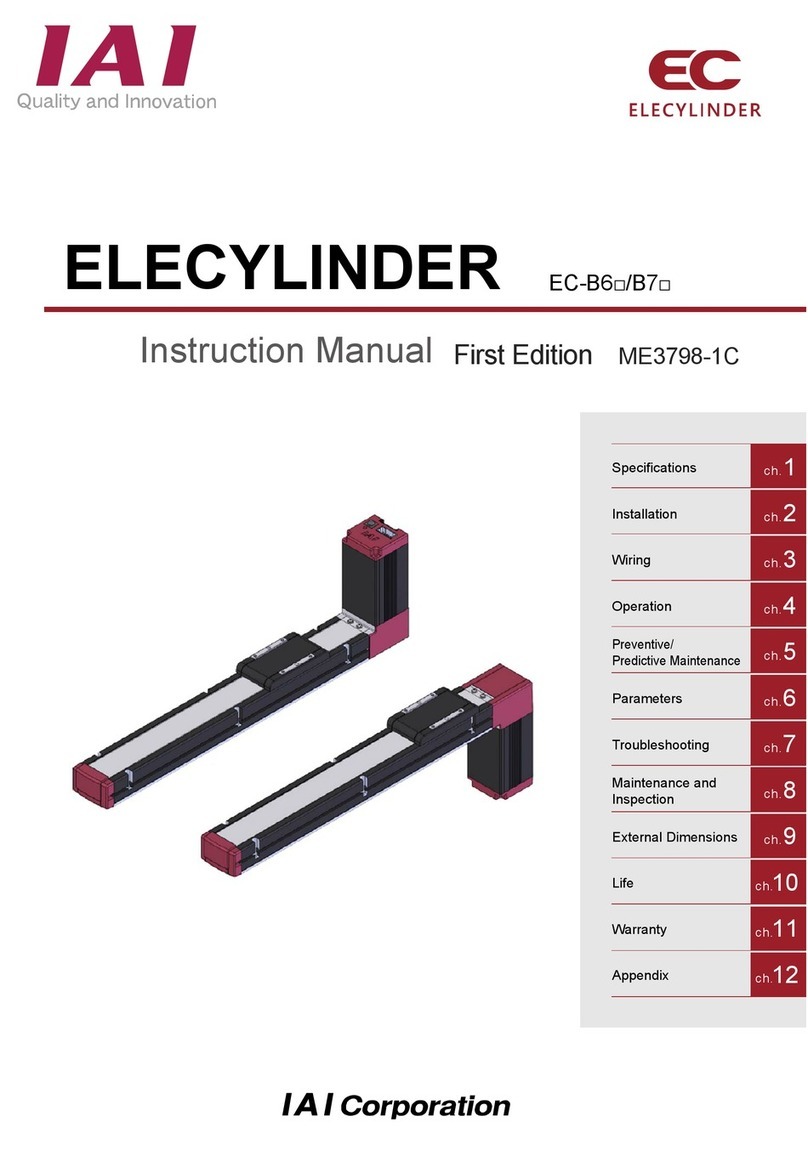

3. VISIBLE ELEMENTS

1. Power switch

2. LCD

3. Knob

4. 230 V 50 Hz power cable of the controller

5. 230 V 50 Hz power cable of the zone 1 device

6. 230 V 50 Hz power cable of the zone 2 device

7. 230 V 50 Hz power cable of the zone 3 device

8. Zone 1 temperature sensor cable

9. Zone 2 temperature sensor cable

10. Zone 3 temperature sensor cable

11. Feeding temperature sensor cable

a. Display

The following information is shown on the display:

arrangement of the controller outputs

current and preset temperatures of the individual outputs

current feeding temperature of the heating system

switched on devices

time and date

controller status (anti-stop, thermal cleansing, heating season: WINTER/SUMMER,

alarms, and others)

EUROSTER 12 – INSTALLATION AND OPERATION MANUAL 3

Example of a screen

b. Meaning of icons shown on the display

H – operation with a weekly schedule

P – active DHW heating priority

P (flashing) – pause in the DHW heating priority

D – thermal cleansing of the DHW switched on

↑ – thermostat mode – heating

↓ – thermostat mode – cooling

– output switched on

WINTER– heating season

AS – anti-stop system active

AF – frost protection switched on

4. CONTROLLER INSTALLATION

Caution!

It is necessary to read this user manual prior to the commencement of the

installation works. Incorrect installation and control of the controller will

result in loss of manufacturer's warranty.

Prior to mounting or dismantling, make sure that the controller is de-

energized.

Voltages hazardous to life may be present on the controller and its cables,

therefore only qualified and authorized technicians may be entrusted with the

installation of the controller.

Ready electric connections and cables used shall be adequate to the applied

loads and must conform to all requirements.

Do not install any controller showing signs of mechanical damage.

The controller is not a safety component of the heating system.

Additional protection devices must be used in the systems prone to the risk of

damage due to failure of the control systems.

Protect the controller against moisture, water, and other liquids.

The controller should be installed in a place where the temperature does not

exceed 40°C.

Using a pair of screws mount the controller box on a wall or any other supporting structure

(screw anchors with screws are supplied with the controller). Screw the power cables to the

connectors of the controlled devices according to the description and figure. Make sure to

keep the proper designation of the cables. Screw the neutral conductors to N terminals,

phase conductors to L terminals, and grounding conductors to PE terminals. Using hose clips

tighten the temperature sensors to the pipes and cover them with thermal insulation.

Moreover, make sure to provide the proper contact with measured surfaces.

EUROSTER 12 – INSTALLATION AND OPERATION MANUAL 4

CAUTION! Do not immerse the temperature sensors in liquids nor install them at

flue gas outlets to the stack.

5. Switching on and operating the controller

The controller is operated by means of a knob with a button. Use the power switch to turn the

controller on. Once the controller is switched on, a main information window is displayed and

an anti–stop system is activated for 15 seconds (AS sign is displayed). Press the knob to

enter the menu. Turn the knob to select the subsequent menu items. Press the knob to select

the required item. Proceed the same way to change the parameters. Exit the menu using the

"Exit" message or by pressing the knob longer (for approximately 3 seconds).

6. Configuration of the controller and restoring factory settings

In order to configure the controller outputs or restore factory settings, perform the following

steps:

keep the knob pressed and turn the controller off and on. A "Factory settings"

configuration window will be displayed

if you want to restore factory settings, set YES for "RESET" parameter

select language of the menu

select operation mode for output No. 1

select operation mode for output No. 2

select operation mode for output No. 3

For each of the outputs, the following operation modes are selectable: Off/ CH/ DHW/

Circulation/ Thermostat/ Floor/ Temporary operation/ Blower/

store the changes by confirming the "STORAGE/Exit" parameter

Caution! Reset does not delete the controller configuration, menu language, date, and time.

7. Description of the menu parameters

Depending on the type of the heating system, each controller should be set up individually,

according to the individual needs.

Caution! It is recommended to restore factory settings before configuring a new controller.

a. For detailed description of the selected operation modes, see point 8.

b. Manual operation

It enables the connected devices to be switched on manually. The test lasts until

leaving the menu.

c. Heating season

It enables switching off the central heating and floor heating zones beyond the heating

season (SUMMER).

Caution! DHW, Circulation, Thermostat, Time-based operation and Blower modes

operate continuously regardless of the selected heating season.

d. Date and Time

These windows enable to enter current date and time. Please remember that only

correct settings enable the proper operation of the schedules and controlling

algorithms.

e. Temperature reading correction

This is a value added to or subtracted from the measured temperature value.

It enables a manual correction of the temperature reading for each temperature

sensor

in the range of +/-5°C.

EUROSTER 12 – INSTALLATION AND OPERATION MANUAL 5

f. Feeding

Setting of the alarm temperature value for the feeding temperature sensor. Upon

exceeding this temperature, an alarm of feeding overheating is generated. CH, DHW,

floor outputs are switched on until the decrease of the feeding temperature below the

preset alarm temperature. Range from 60°C to 110°C.

8. Description of the operation modes

The following diagrams are simplified and do not cover all the elements necessary for the

correct operation of the system.

a. CH MODE – OPERATING THE CENTRAL HEATING CIRCULATION PUMP

Designations:

1. Feeding temperature sensor

2. CH zone pump

3. The zone temperature sensor for

which the CH mode was selected.

Operating conditions:

The CH pump is activated if:

the CH system is switched on;

the current time is selected in the schedule;

the temperature of the feeding sensor reaches the value of the "Switch-on

temperature" setting.

The CH pump is deactivated if the temperature of the feeding sensor drops by the

hysteresis value below the "Switch-on temperature" setting.

The weekly schedule of the CH pump operation enables switching the zone off for the

selected hours in the selected days of the week.

The zone overheating alarm is generated if the temperature of the zone sensor

exceeds the value of the "Alarm temperature" setting. If the alarm temperature is

maintained longer than for one minute, then the zone pump is switched off.

In the case when the hourly schedule for the pump operation is not marked (heating

not needed), the pump operates in cycles, according to the "Operating time" and "Idle

time" settings. If "Operating time" = 0 is set, then the pump is not switched on.

Caution! When setting the alarm temperature, special precautions must be taken in order

not to damage the system or CH boiler.

EUROSTER 12 – INSTALLATION AND OPERATION MANUAL 6

CH mode settings table

Mode

Parameter

Value

default

Description

CH

On/Off

On

Switches the zone on or off.

Switch-on

temperature

35°C

The temperature above which the pump is

switched on. Range from 10°C to 90°C.

Schedule

All hours on.

Weekly schedule of the CH pump operation

Alarm

temperature

95°C

The temperature above which the pump is

switched off

generates the alarm. Range from 80°C to

110°C.

Maintenance

Operation – 10

minutes

Idle time – 50

minutes

The function is active when the hourly schedule

is not selected.

"Operating time" setting range – from 0 to 600

min.

"Idle time" setting range – from 1 to 600 min.

Hysteresis

2°C

It is a difference between the temperature at

which the CH pump is switched on and off.

Range from 2°C to 10°C.

Exit

-

-

b. DHW MODE – CONTROL OF THE DOMESTIC HOT WATER TANK FEEDING PUMP

Designations:

1. Feeding temperature sensor

2. DHW tank feeding pump

3. The tank temperature sensor for

which the DHW mode was

selected.

Operating conditions:

The DHW pump is activated if:

the DHW system is switched on;

the current time is selected in the schedule;

the temperature of the DHW sensor drops by the value of the hysteresis below

the DHW preset temperature;

the temperature of the feeding sensor will be higher by the "Excess" parameter

than the tank temperature;

the feeding sensor temperature will be higher than the "DHW start

temperature" setting.

The weekly schedule of the DHW pump operation enables switching the zone off for

the selected hours in the selected days of the week.

The thermal cleansing function consists in heating the tank up to the temperature of

70°C. The time for performance of the thermal cleansing is limited to 4 hours.

Maintaining a low DHW temperature (at the level of 40°C) facilitates the development

of bacterial flora in the system. The proper cleansing consists in heating the DHW tank

EUROSTER 12 – INSTALLATION AND OPERATION MANUAL 7

to the temperature of 70°C and flushing the pipes with hot water.

The “Excess” parameter determines the value by which the temperature of the heat

source must exceed the temperature of the tank. Setting a higher temperature

ensures an adequate heating capacity and compensates the heat loss due to the

imperfect insulation of pipes connecting the boiler and the tank. If the temperature of

the heat source is not sufficiently high, then the DHW tank feeding pump is not

switched on.

The overheating alarm is generated if the temperature of the zone sensor exceeds the

value of the "Alarm temperature" setting and is maintained longer than for one

minute.

Switching on of the "Priority" function means that the controller switches off the CH

circuits for the time of DHW heating in order to achieve the temperature preset for the

tank as fast as possible. In the case when the tank cannot be heated up in a

reasonable time, it is possible to limit the DHW priority. The DHW tank is heated for

the time preset by the “Operation time” parameter (Picon active on the display

screen), then the DHW priority is switched off for the “priority break time”. – the

pumps operate simultaneously (Picon flashing on the display). Subsequently, the

priority is switched on again. Only CH and Floor zones implement the “priority”

function.

The "DHW start temperature" parameter determines the threshold of the DHW pump

activation. If the temperature of the feeding sensor exceeds the DHW start

temperature, the pump is activated.

DHW mode settings table

Mode

Parameter

Default

value

Description

DHW

On/Off

On

Switches the zone on or off.

Preset

temperature

50°C

DHW tank preset temperature

Range from 30°C to 95°C.

Schedule

All hours

on.

Weekly schedule of the DHW pump operation.

DHW thermal

cleansing

Off

Enables performance of thermal cleansing of the

DHW system.

Hysteresis

5°C

It is a difference between the temperature at which

the tank feeding pump is switched on and off.

Range from 2°C to 10°C.

Excess

5°C

Determines the value by which the temperature of

the heat source must exceed the temperature of the

tank. Range from 2°C to 10°C.

Alarm temp.

85°C

The temperature above which the tank overheating

alarm is generated.

Range from 75°C to 95°C.

Priority

Off

Enables switching the DHW operating priority over

the CH and floor heating pumps on or off.

"Operating time" setting range – from 1 to 99 min.

"Idle time" setting range – from 1 to 99 min.

DHW start

temperature

40°C

DHW pump activation threshold

Range from 10°C to 80°C.

Exit

-

-

EUROSTER 12 – INSTALLATION AND OPERATION MANUAL 8

c. CIRCULATION MODE – CIRCULATION OF THE DOMESTIC HOT WATER ZONE

Designations:

1. DHW circulation pump

2. The zone temperature sensor for

which the "Circulation" mode was

selected.

Operating conditions:

The circulation pump is activated if:

the circulation zone is active;

the current time is selected in the schedule;

the temperature of the zone sensor decreases below the preset temperature by

the value of the hysteresis.

The pump is switched off if the temperature of the zone sensor achieves the preset

temperature.

The zone overheating alarm is generated after one minute from the moment of

exceeding the "Alarm temperature" setting.

Circulation mode settings table

Mode

Parameter

Default

value

Description

DHW

Circulation

"Circ"

On/Off

On

Switches the zone on or off.

Temperature

40°C

Preset temperature of the zone. Range from 20°C

to 70°C.

Schedule

All hours

on.

Weekly schedule of the DHW circulation pump

operation.

Hysteresis

5°C

It is a difference between the temperature at

which the circulation pump is switched on and

off.

Range from 2°C to 10°C.

Alarm temp.

75°C

The temperature above which the zone

overheating alarm is generated.

Range from 70°C to 95°C.

Exit

-

-

d. THERMOSTAT MODE – MODE OF OPERATION AS A PROGRAMMABLE THERMOSTAT

WITH A HEATING OR COOLING FUNCTION

HEATING Tswitch on < Tswitch off

COOLING Tswitch on < switch off

The temperature sensor of the zone for which the "Thermostat" mode was selected is

used in this mode.

Operating conditions:

The output is activated if:

the zone is active;

the current time is selected in the schedule;

according to the "T switch on" and "T switch off" settings.

EUROSTER 12 – INSTALLATION AND OPERATION MANUAL 9

The Heating/Cooling parameter enables selecting whether the zone is to control

heating or cooling.

The feeding temperature is disregarded in this mode.

Thermostat mode settings table

Mode

Parameter

Default

value

Description

Thermostat

"Thermo"

On/Off

On

Switches the zone on or off.

T switch on

28°C

Switch-on temperature.

Range from 0°C to +95°C

T switch off

30°C

Switch-off temperature.

Range from 0°C to +99°C

Schedule

All hours

on.

Weekly schedule of the Thermostat output

operation.

Heating/

Cooling

Heating

Enables selecting whether the thermostat circuit is

to control heating or cooling.

Exit

-

-

e. FLOOR MODE – CONTROL OF THE FLOOR HEATING ZONE

Designations:

1. Feeding temperature sensor

2. Floor zone pump

3. The zone temperature sensor for

which the "Floor" mode was

selected.

4. Thermostatic valve

Operating conditions:

The floor pump is activated if:

the zone is active;

the current time is selected in the schedule;

the temperature of the feeding sensor exceeds the value of the switch-on

temperature setting (Switch-on temp.);

the temperature of the floor zone temperature sensor is maintained below the

switch-off temperature setting (Switch-off temp.).

The temperature sensor downstream of the pump is used for controlling the

temperature of the floor zone. The pump will be switched off when the temperature of

the sensor reaches the switch-off temperature (switch-off temp.) and will be switched

on when the temperature of the zone sensor drops by the hysteresis value below the

switch-off temperature.

The zone overheating alarm is generated after one minute from the moment of

exceeding the "Alarm temperature" setting. The alarm temperature setting must be

higher than the switch-off temperature.

In the case when the hourly schedule for the pump operation is not marked (heating

not needed), the "Maintenance" function is implemented" – the pump operates in

EUROSTER 12 – INSTALLATION AND OPERATION MANUAL 10

cycles, according to the "Operating time" and "Idle time" settings.

If "Operating time" = 0 is set, then the pump is not switched on.

Floor mode settings table.

Mode

Parameter

Value

default

Description

Floor

"Floor"

On/Off

On

Switches the zone on or off.

Switch-on

temperature

20°C

The temperature above which the pump is switched

on. Range from 10°C to 60°C.

Switch-off

temperature

45°C

The temperature above which the pump is switched

off.

The switch-off temperature must be lower than the

alarm temperature.

Range from 20°C to 50°C.

Schedule

All hours

on.

Weekly schedule of the floor pump operation.

Alarm

temperature

50°C

The temperature above which the zone overheating

alarm is generated.

Range from 21°C to 60°C.

Maintenance

Operation –

10 minutes

Idle time –

50 minutes

The function is active when the hourly schedule is

not selected.

"Operating time" setting range – from 0 to 600 min.

"Idle time" setting range – from 1 to 600 min.

Hysteresis

2°C

It is a difference between the temperature at which

the pump is switched on and off.

Range from 2°C to 10°C.

Exit

-

-

f. TIME-BASED OPERATION MODE – MODE OF OPERATION WITH PROGRAMMABLE

OPERATING TIME AND IDLE TIME

1. The temperature sensors are not used in

this mode.

2. The output may be used for the time-

based control of, e.g., lighting, ventilation.

Operating conditions:

The transmitter is activated if:

the output is active;

the current time is selected in the schedule;

according to the "Operating time" and "Idle time" settings – operation in cycles.

In the case when the hourly schedule of the pump operation is not marked (empty

cells), the output is not switched on.

If the "Idle time" = 0 is set, then the output operates at all times.

EUROSTER 12 – INSTALLATION AND OPERATION MANUAL 11

Time-based operation mode settings table

Mode

Parameter

Value

default

Description

Time-

based

operation

"Temp.op."

On/Off

On

Switches the zone on or off.

Operating time

10 minutes

Range from 1 min to 600 min.

Idle time

30 minutes

Range from 0 min to 600 min.

Schedule

All hours

on.

Weekly schedule of the output operation.

Exit

-

-

g. BLOWER MODE – MODE OF OPERATION CONTROLLING THE CH BOILER BLOWER

(WITHOUT SPEED ADJUSTMENT)

Designations:

1. CH pump

2.

The zone temperature sensor for

which the "Blower" mode was

selected.

3. Blower

Operating conditions:

The transmitter is activated if:

the output is active;

the current time is selected in the schedule;

the temperature of the sensor is maintained below the "Preset temperature"

setting.

The FIRING-UP function is activated by switching the controller off and on again with

the power button. The blower operates for 60 minutes and if during this period the

zone temperature does not reach the shutdown temperature, then the controller

switches the blower off and terminates the firing-up process.

Exceeding the boiler temperature ("Preset temperature") results in turning into the

blow-through operation. The blower operates time-based, according to the "Blow-

through time" and "Blow-through idle time". In this operation mode, the blower is

started only to remove combustion gases out of the furnace. The blow-throughs are

implemented until the temperature drops by the hysteresis value below the preset

temperature.

In the case when the hourly schedule of the pump operation is not marked (heating

not needed), the preset temperature is decreased by the "Reduction" parameter.

The zone overheating alarm is generated after one minute from the moment of

exceeding the "Alarm temperature" setting. The blow-throughs are not performed

then.

The zone temperature sensor shall be located along with the feeding temperature

sensors (possibly close to the boiler).

"Shutdown" – a temperature below which the controller turns the blower off (the fire is

considered shut down).

EUROSTER 12 – INSTALLATION AND OPERATION MANUAL 12

Blower mode settings table

Mode

Parameter

Value

default

Description

Blower

"Blower"

On/Off

On

Switches the zone on or off.

Temperature

60°C

Preset temperature.

Range from 15°C to 85°C.

Schedule

All hours

on.

Weekly schedule of the blower operation.

Hysteresis

5°C

It is a difference between the temperature at which

the blower is switched on and off.

Range from 2°C to 10°C.

Temp. reduction

5°C

Reduction of the preset temperature by a preset

value. Range from 2°C to 10°C.

Alarm

temperature

95°C

The temperature above which the alarm is

generated. Range from 90°C to 95°C.

Blow-through

time

10 seconds

Blow-through time. Range from 1 s to 99 s.

Blow-through

idle time.

5 minutes

Idle time between the blow-throughs.

Range of 1 min to 99 min.

Shutdown

35°C

Range from 10°C to 50°C.

Exit

-

-

9. Anti-stop system

EUROSTER 12 controller is equipped with an ANTI-STOP system that prevents the process of

scale build-up on the rotors of unused pumps. It automatically turns the pumps on every

10 days when the heating season is over. Keep the controller turned on to allow the function

operation after the heating season.

The anti-stop system is implemented for the CH, DHW, Circulation, Floor modes.

10. Alarm situations

To ensure safe and reliable operation, the controller features a number of protections. The list

of alarm events is shown in the table below. If an alarm situation occurs, an audible alarm is

generated and a relevant message is displayed. Upon resolution of the alarm situation, the

controller automatically resumes its operation. The message is displayed until the menu is

entered. If the alarm is resolved, the message is erased upon exiting the menu.

Alarm

Message

Controller response

Feeding sensor

shorted

Supply sens. shorted

Switching on of the outputs (CH, Floor) and

activation of an audible alarm.

Opening of the

feeding sensor

Feeding sens. open

Switching on of the outputs (CH, Floor) and

activation of an audible alarm.

Feeding sensor

overheating

Feed. sens.

overheating

Switching on of the outputs (CH, DHW, Floor)

and activation of an audible alarm.

Zone 1 sensor

shorted

Sens. shorted 1

Switching off of the output, activation of an

audible alarm

Zone 1 sensor open

Sens. open 1

Switching off of the output, activation of an

audible alarm.

Zone 1 sensor

overheating

Sens. overheating 1

Switching off of the output, activation of an

audible alarm.

Zone 2 sensor

shorted

Sens. shorted 2

Switching off of the output, activation of an

audible alarm.

EUROSTER 12 – INSTALLATION AND OPERATION MANUAL 13

Zone 2 sensor open

Sens. open 2

Switching off of the output, activation of an

audible alarm.

Zone 2 sensor

overheating

Sens. overheating 2

Switching off of the output, activation of an

audible alarm.

Zone 3 sensor

shorted

Sens. shorted 3

Switching off of the output, activation of an

audible alarm.

Zone 3 sensor open

Sens. open 3

Switching off of the output, activation of an

audible alarm.

Zone 3 sensor

overheating

Sens. overheating 3

Switching off of the output, activation of an

audible alarm.

11. Maintenance

Before each and every heating season, the controller must be cleaned of any dust and dirt,

the cables must be checked for tight fixing. If necessary, wipe it carefully with a soft cloth. Do

not use solvents and aggressive detergents since they may damage the surface of the

housing and the display. Avoid contact with water or other liquids.

12. Internal battery

The controller is equipped with an internal battery, unavailable for the user. Do not try to

replace it by yourself. For further information on replacement or repair of the controller

(no clock backup after blackout), please contact our technical support.

13. Dimensions

EUROSTER 12 – INSTALLATION AND OPERATION MANUAL 14

14.Technical data

Controlled device: pumps and other devices used in heating

systems

Supply voltage: 230 V 50 Hz

Maximum load of each of the outputs: 1 A 230 V 50 Hz

Maximum power consumption of the controller: 3 W

Temperature measurement range: from -5°C to +100°C

Temperature adjustment range: CH mode: from +10°C to +90°C

DHW mode: from +30°C to +95°C

Circulation mode: from +20°C to +70°C

Floor mode: from +10°C to +60°C

Blower mode: from +15°C to +85°C

Thermostat mode: from 0°C to +99°C

Temperature control accuracy: 1°C

Hysteresis range: from 2°C to 10°C

Visual signalization: backlit LCD

Operation temperature: from +5°C to +40°C

Storage temperature: from 0°C to +50°C

Ingress protection rating: IP40

Color: black

Mounting method: wall-mounted

Controller weight: 0.84 kg

Standards, approvals, certificates: conformity to EMC, LVD, and RoHS

Warranty period: 2 years

Dimensions (width / height / depth) in mm: 150 / 90 / 52

Line protection: WTA-T4A time lag fuse (inside the controller)

Length of cables:

Power cable of the controller: 1.5 m

Power cable of device No. 1: 1.5 m

Power cable of device No. 2: 1.5 m

Power cable of device No. 3: 1.5 m

Zone 1 temperature sensor: 1.5 m

Zone 2 temperature sensor: 3 m

Zone 3 temperature sensor: 5 m

Feeding temperature sensor: 1.5 m

15. KIT CONTENTS

Euroster 12 controller

Sensor hose clips (4 pcs)

Screw anchors (2 pcs)

Mounting template

User Manual with Warranty Certificate

16. STANDARDS AND CERTIFICATES

Euroster 12 controller conforms to the following EU Directives: EMC, LVD, and ROHS.

The EC Declaration of Conformity is published and available at:

http://www.euroster.com.pl

EUROSTER 12 – INSTALLATION AND OPERATION MANUAL 15

17.ELECTRONIC WASTE MANAGEMENT INFORMATION

We made every effort to ensure that this controller lifetime is as long as

possible.

However, the device is subject to natural wear. If the device would not meet your

requirements any more, you are kindly requested to have it brought in to an

electronic waste management facility. Cardboard boxes must be disposed at a

paper recycling facility.

WARRANTY CERTIFICATE

EUROSTER 12 controller

Warranty terms:

1. The warranty is valid for 24 months from the device sale date.

2. Claimed thermostat together with this warranty certificate must be supplied to the

seller.

3. Warranty claims shall be processed within 14 business days from the date the

manufacturer has received the claimed device.

4. The device may be repaired exclusively by the manufacturer or by other party clearly

authorized by the manufacturer.

5. Warranty becomes invalidated in case of any mechanical damage, incorrect operation

and/or making any repairs by unauthorized persons.

6. This consumer warranty does not exclude, restrict nor suspend any right of the Buyer

ensuing if the product would not meet any of the sale contract terms.

.................................................................................................................................

sale date

serial number/ date of

manufacture

stamp

and signature

service:

tel. 65-57-12-012

Business entity that issued this warranty certificate is:

P.H.P.U. AS Agnieszka Szymańska-Kaczyńska, Chumiętki 4, 63-840 Krobia, Poland

Table of contents

Other EUROSTER Controllers manuals

EUROSTER

EUROSTER 11Z User manual

EUROSTER

EUROSTER 10M User manual

EUROSTER

EUROSTER 11WB User manual

EUROSTER

EUROSTER 10PC User manual

EUROSTER

EUROSTER 1100E User manual

EUROSTER

EUROSTER 11W User manual

EUROSTER

EUROSTER C6RX User manual

EUROSTER

EUROSTER 11B User manual

EUROSTER

EUROSTER UNI2 User manual

EUROSTER

EUROSTER 813 User manual

EUROSTER

EUROSTER FH1 User manual

EUROSTER

EUROSTER 11WBZ User manual

EUROSTER

EUROSTER UNI3 User manual

EUROSTER

EUROSTER 11E User manual

EUROSTER

EUROSTER 11Z User manual

EUROSTER

EUROSTER 12M User manual

EUROSTER

EUROSTER 11W User manual

EUROSTER

EUROSTER 11M User manual

EUROSTER

EUROSTER 11E User manual

EUROSTER

EUROSTER 11K User manual