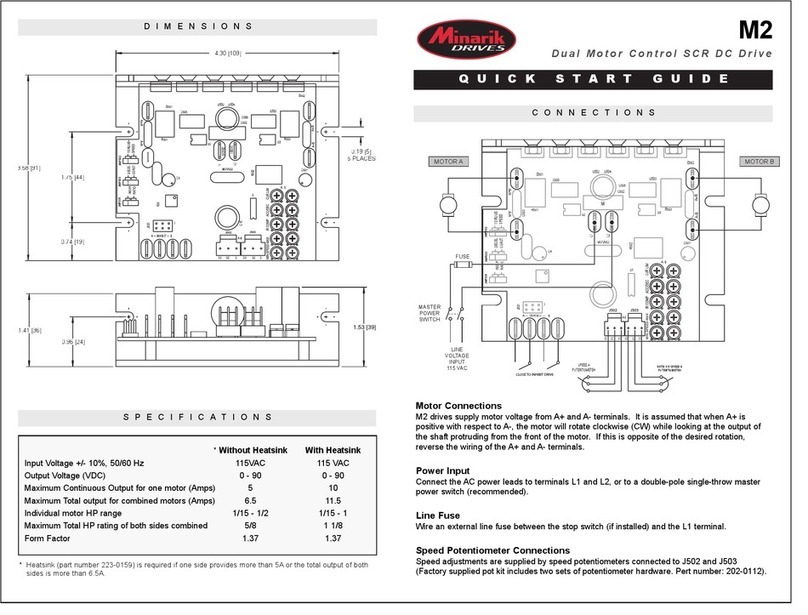

Minarik M2-D User manual

Other Minarik DC Drive manuals

Minarik

Minarik HTL05-D-4Q User manual

Minarik

Minarik RG501A User manual

Minarik

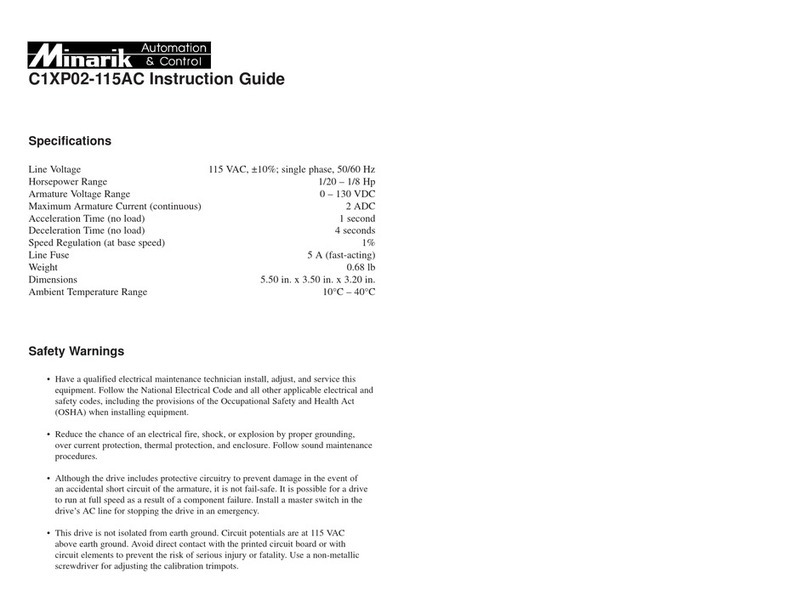

Minarik C1XP02-115AC Manual

Minarik

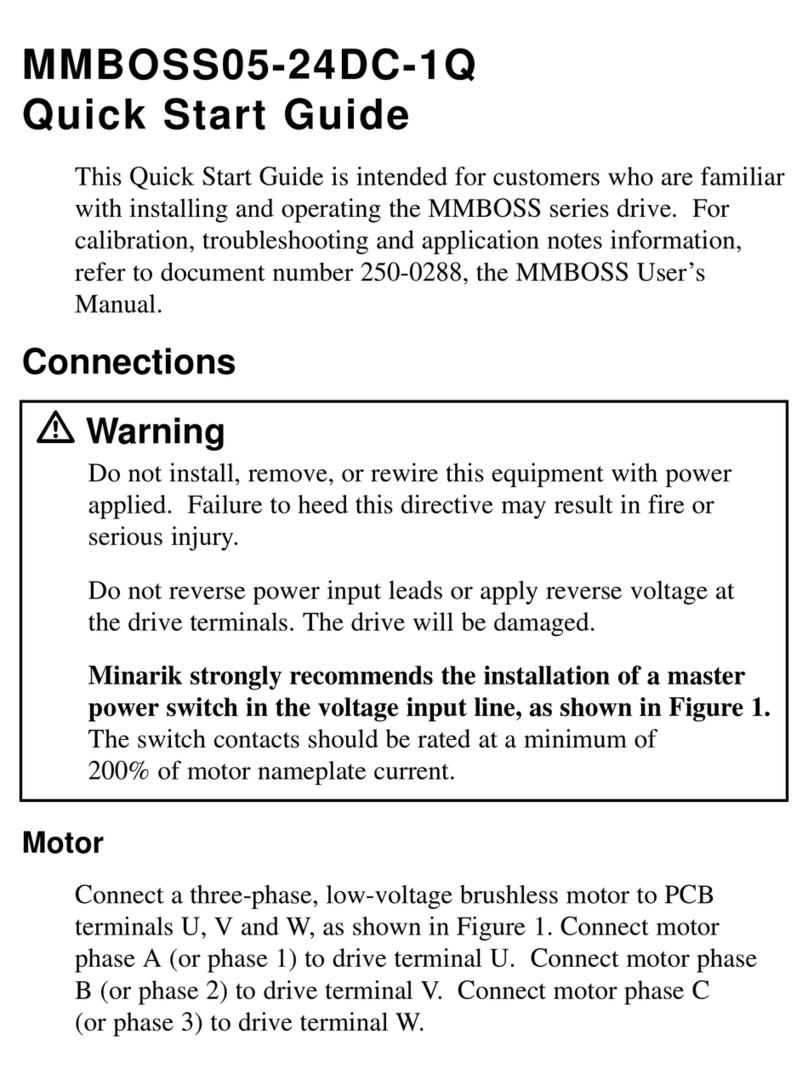

Minarik MMBOSS Series User manual

Minarik

Minarik MM300 Series User manual

Minarik

Minarik MMRG Series User manual

Minarik

Minarik M2 User manual

Minarik

Minarik XP-AC Series User manual

Minarik

Minarik MM21036A User manual

Minarik

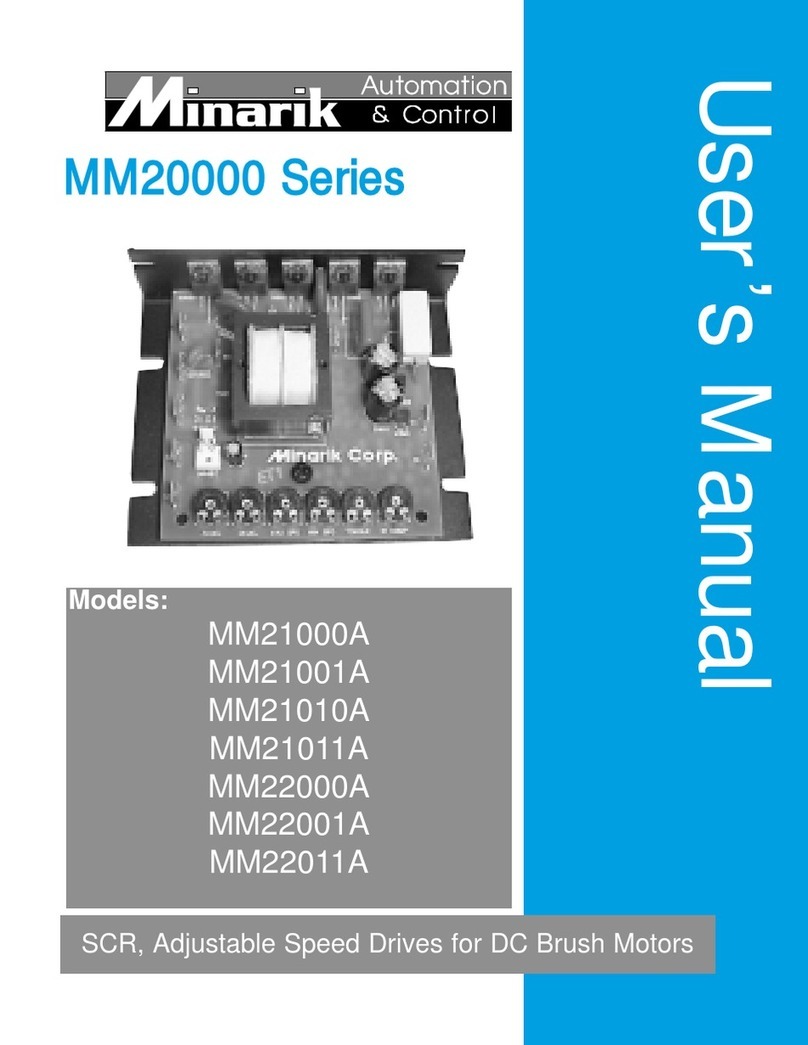

Minarik MM20000A Series User manual

Minarik

Minarik PCM23000A Series User manual

Minarik

Minarik NRG-2Q Series User manual

Minarik

Minarik RG500 Series User manual

Minarik

Minarik BOSS Series User manual

Minarik

Minarik RG5500U User manual

Minarik

Minarik BOSS Series User manual

Minarik

Minarik Motor Master 20000 Series User manual

Minarik

Minarik PCM21000A User manual

Minarik

Minarik MM-PCM Series User manual

Minarik

Minarik DC30-12-4Q-L User manual

Popular DC Drive manuals by other brands

HP

HP StorageWorks Ultrium 960 User's and service guide

Parker

Parker E-DC Hardware installation guide

Fuji Electric

Fuji Electric FRENIC-Eco Series quick guide

Lenze

Lenze L-force 8400 HighLine C Push Through Series Mounting instructions

Eaton

Eaton M-Max series quick start guide

I.CH Motion

I.CH Motion 3P20M owner's guide

Parker

Parker 590+ DRV product manual

Romac Industries Inc.

Romac Industries Inc. 371-00 operating manual

Danfoss

Danfoss VLT FC 103 operating guide

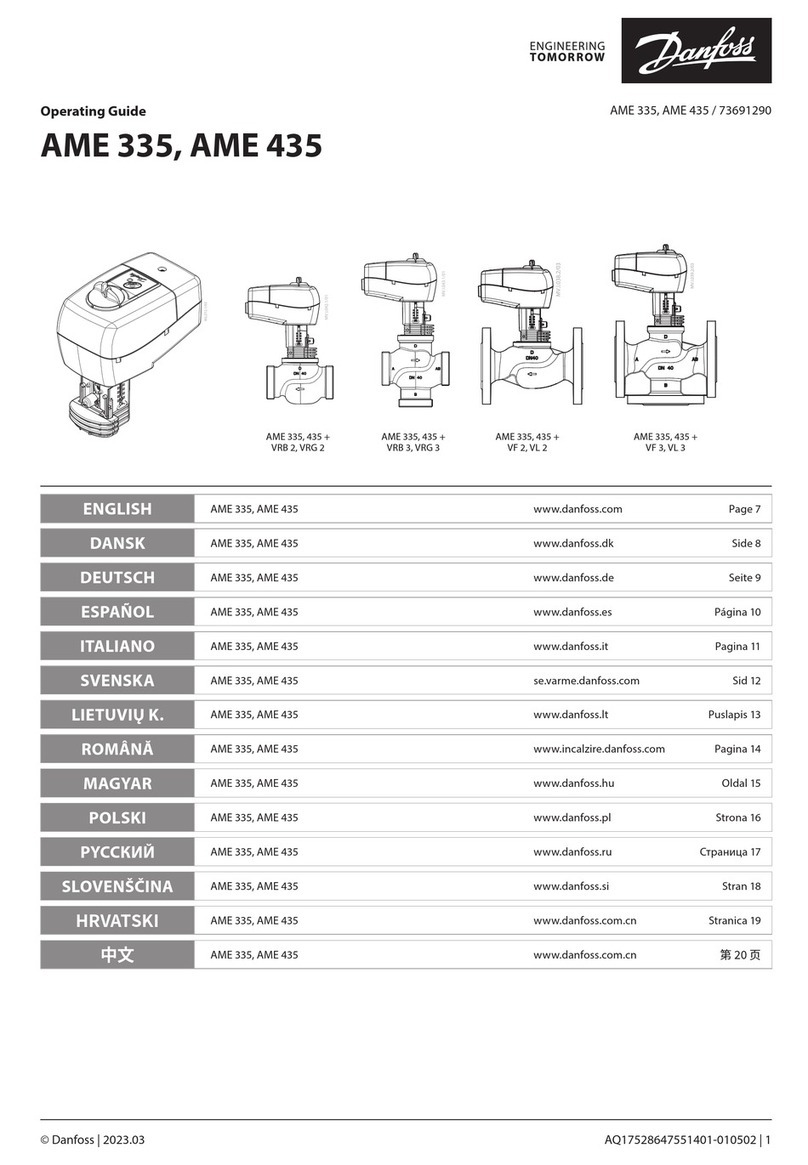

Danfoss

Danfoss 73691290 operating guide

Pfeiffer Vacuum

Pfeiffer Vacuum TC1200 operating instructions

Kollmorgen

Kollmorgen MMC Smart Drive Series Hardware manual

Vacon

Vacon 100 INDUSTRIAL Application guide

ABB

ABB ACS260-04 Series Quick installation and start-up guide

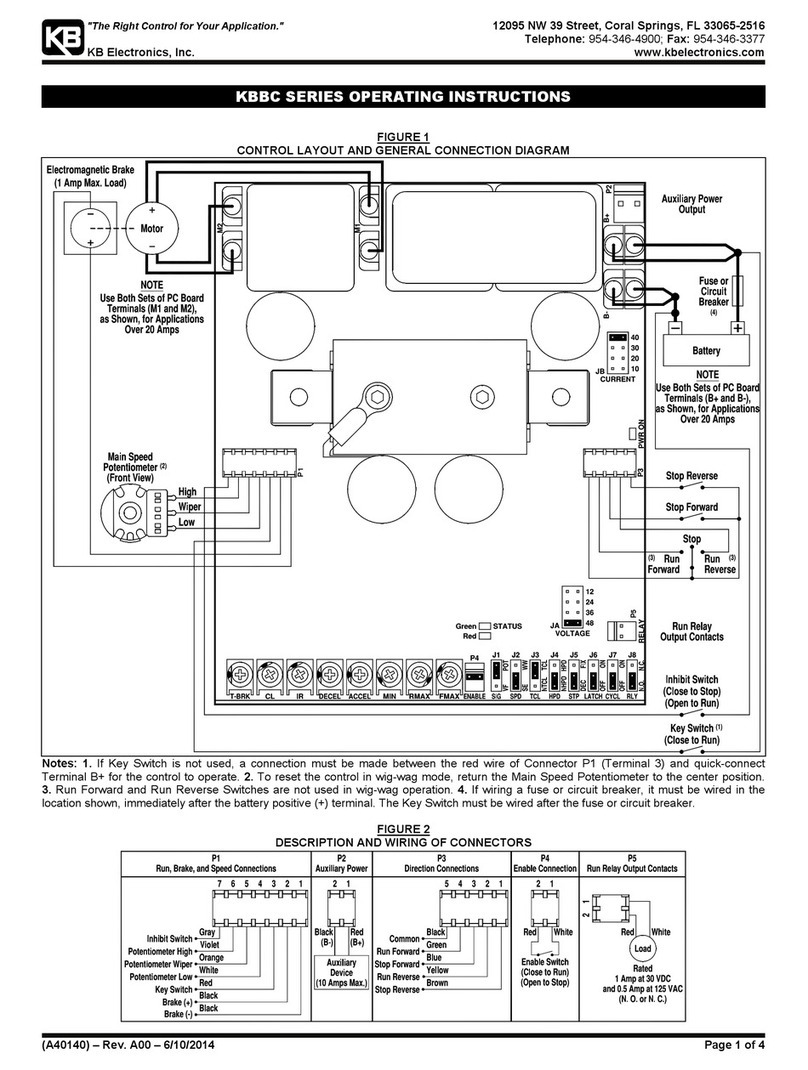

KB Electronics

KB Electronics KBBC Series operating instructions

Gentlefile

Gentlefile GF-CAP-01 Instructions for use

Minolta

Minolta MD-90 owner's manual

GFA

GFA ELEKTROMAT SI 40.24-40,00 installation instructions