Minarik C1XP02-115AC Manual

Other Minarik DC Drive manuals

Minarik

Minarik PCM23000A Series User manual

Minarik

Minarik BOSS Series User manual

Minarik

Minarik RG500 Series User manual

Minarik

Minarik XP-AC-SL Series User manual

Minarik

Minarik NRGD-4Q Series User manual

Minarik

Minarik MMRG30U User manual

Minarik

Minarik MMBOSS Series User manual

Minarik

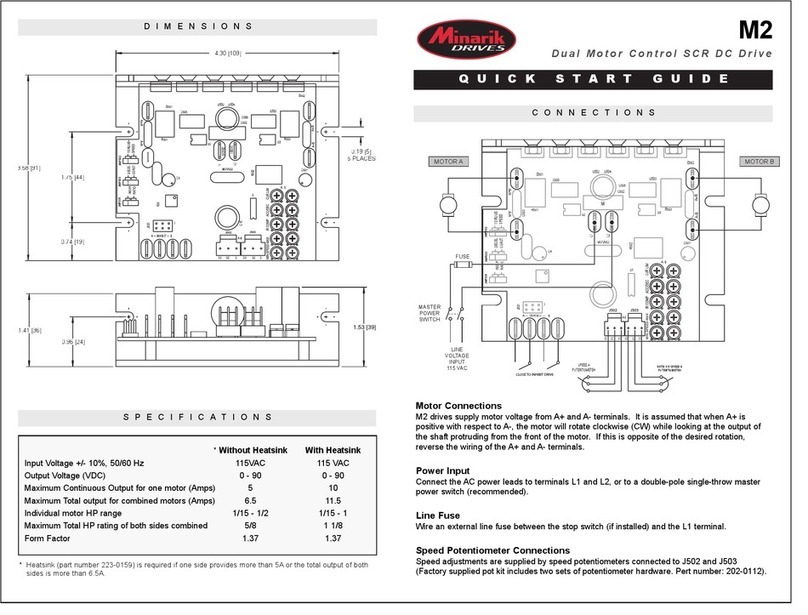

Minarik M2 User manual

Minarik

Minarik Motor Master 20000 Series User manual

Minarik

Minarik VFD Series User manual

Minarik

Minarik MM-PCM Series User manual

Minarik

Minarik XL1100A User manual

Minarik

Minarik MMBOSS Series User manual

Minarik

Minarik MM21036A User manual

Minarik

Minarik MM20000A Series User manual

Minarik

Minarik HTL05-D-4Q User manual

Minarik

Minarik MM20000 Series User manual

Minarik

Minarik DC30-12-4Q-L User manual

Minarik

Minarik M2-D User manual

Minarik

Minarik VFDP4X04-D230-PCM User manual

Popular DC Drive manuals by other brands

SEW-Eurodrive

SEW-Eurodrive X e/HM Series Assembly and operating instructions

D+H

D+H ZA 35-K-BSY+ instructions

Danfoss

Danfoss FC 301 instruction manual

INVT

INVT Goodrive350 Series Operation manual

Franklin

Franklin Q-link Installation, Programming Operation, & Maintenance Manual

Danfoss

Danfoss VLT Micro Drive FC 51 Series quick guide

LinMot

LinMot E1250-LU-UC manual

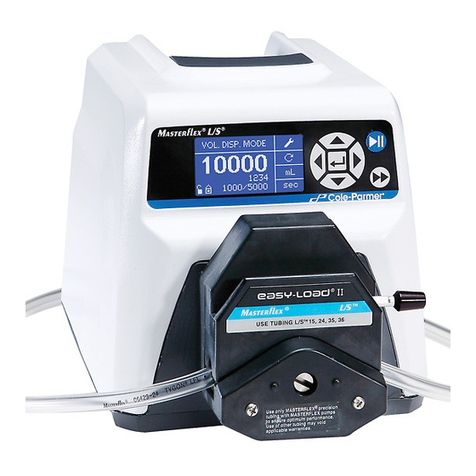

Masterflex

Masterflex L/S Series quick start guide

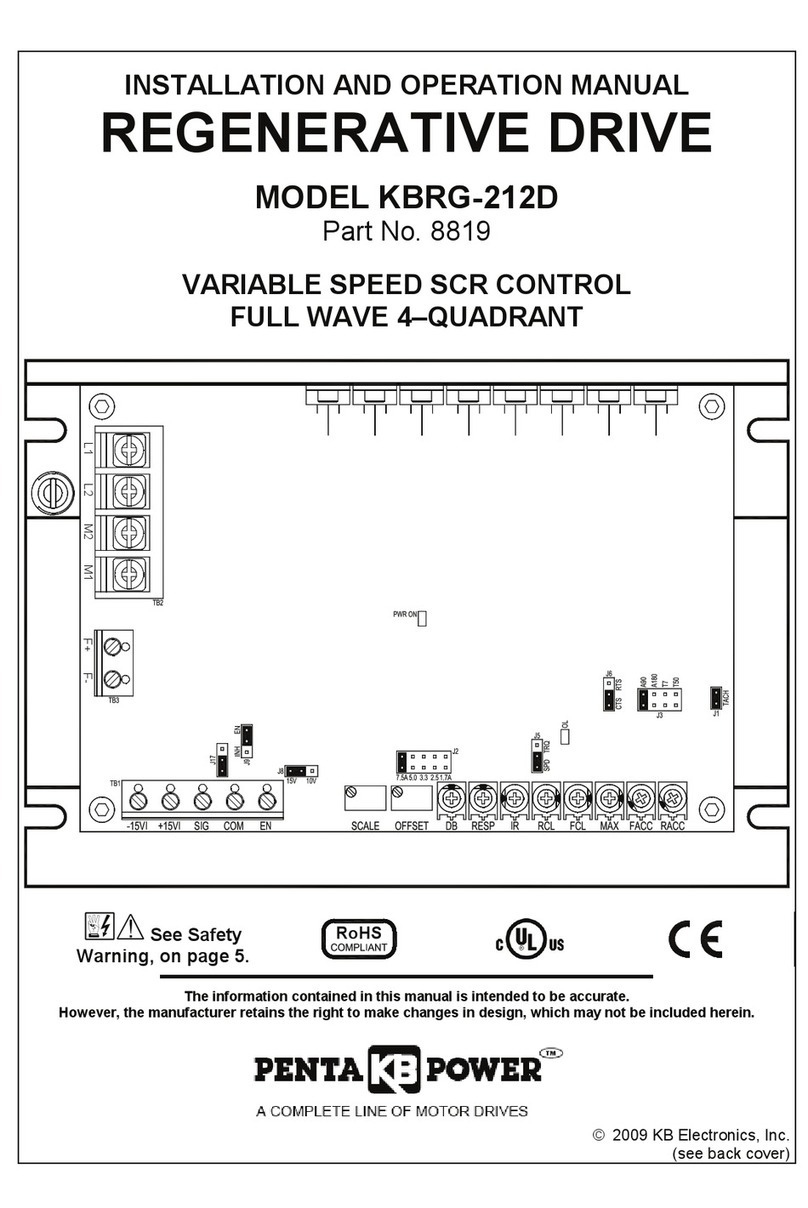

KB Electronics

KB Electronics Penta Power KBRG-212D Installation and operation manual

itema

itema PROMATECH LEONARDO SILVER HI DRIVE 7000 user manual

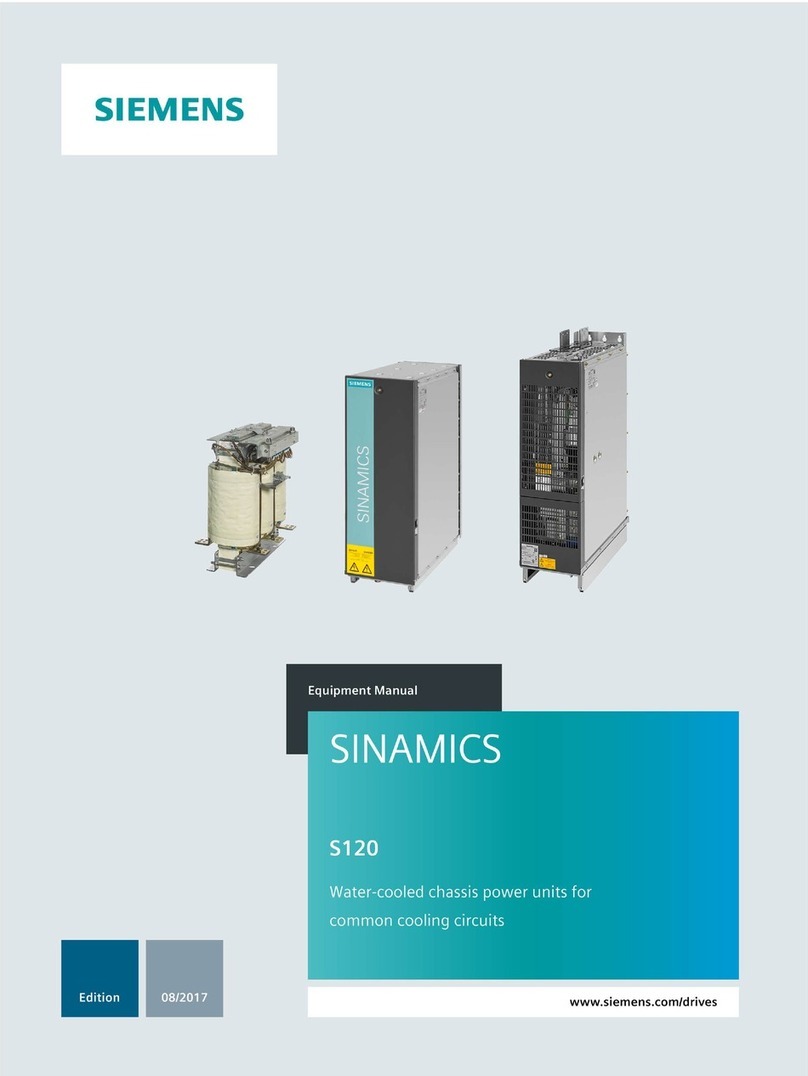

Siemens

Siemens SINAMICS S120 Equipment manual

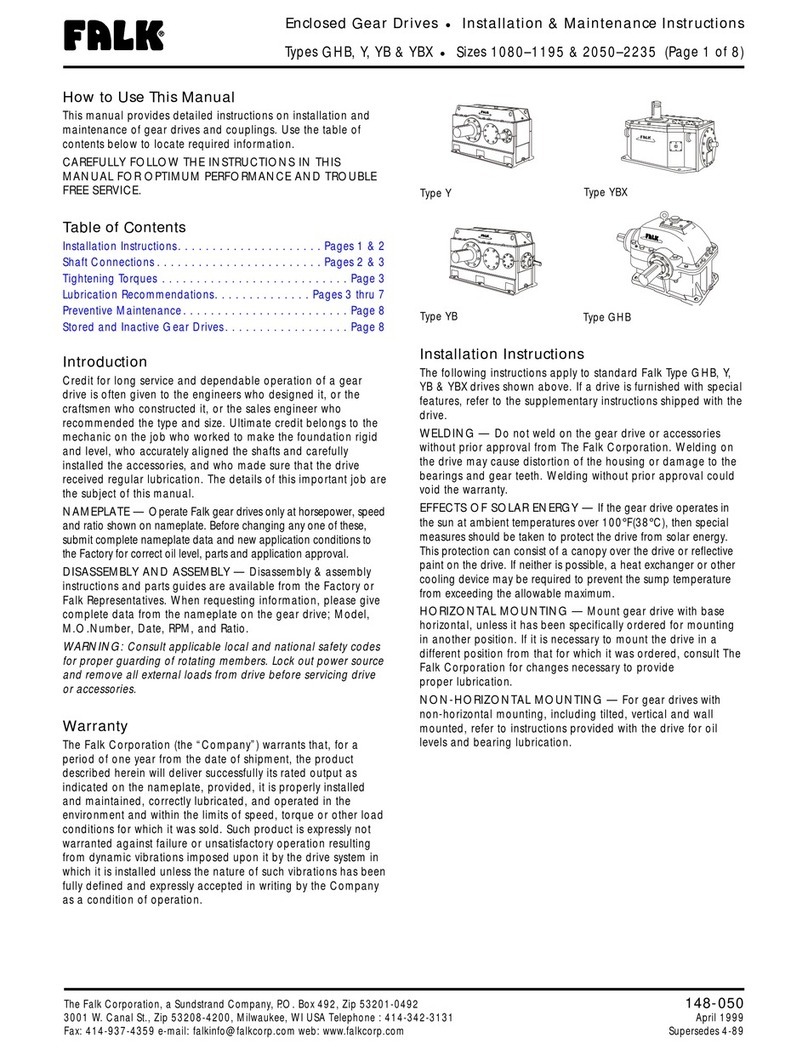

FALK

FALK GHB Series Installation & maintenance instructions