4

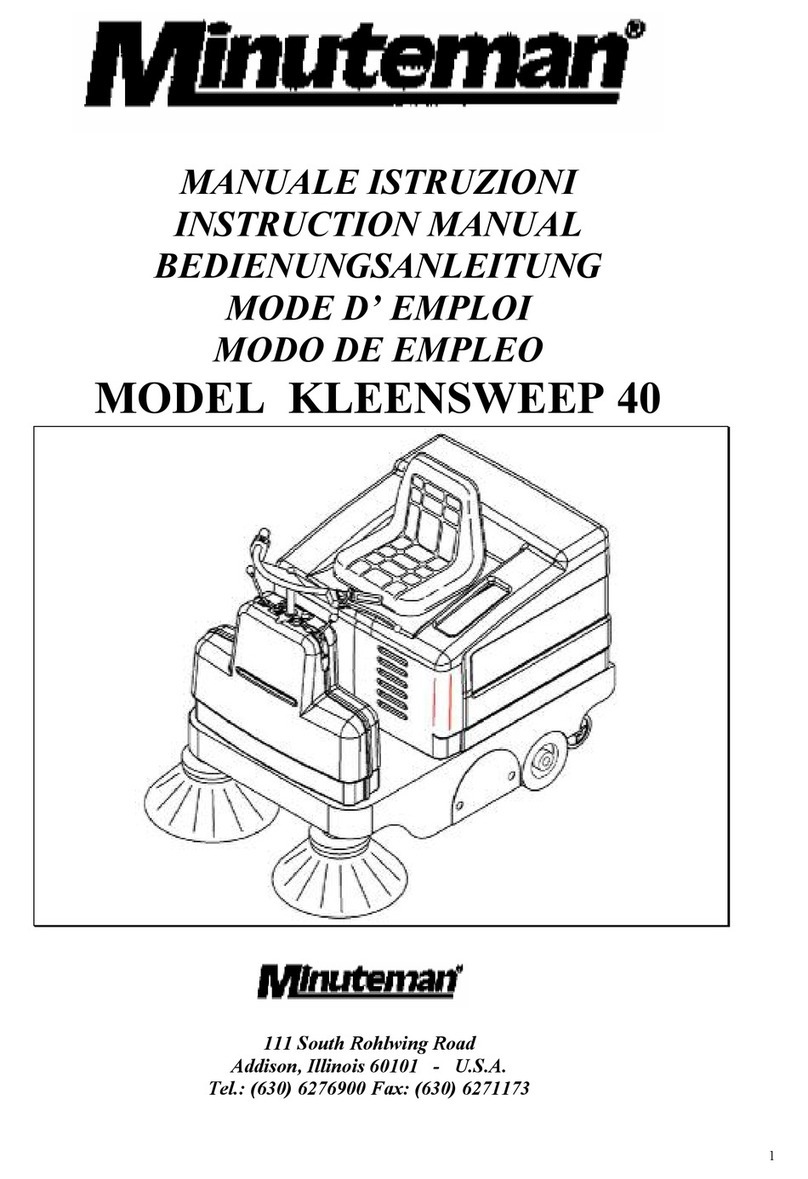

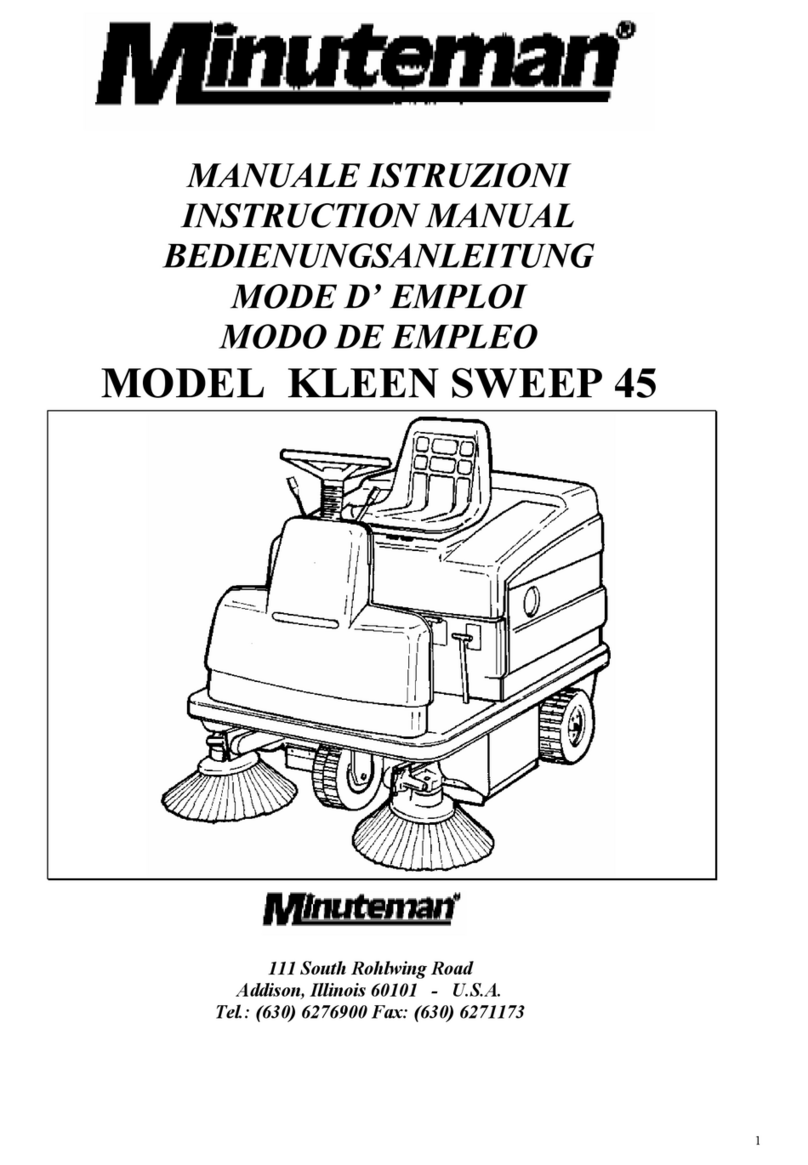

TABLE OF CONTENTS

Operation, Illustration, Spare Parts, and Maintenance

IMPORTANT SAFETY INSTRUCTIONS ............................................................. 5

INSPECTION ................................................................................................................6

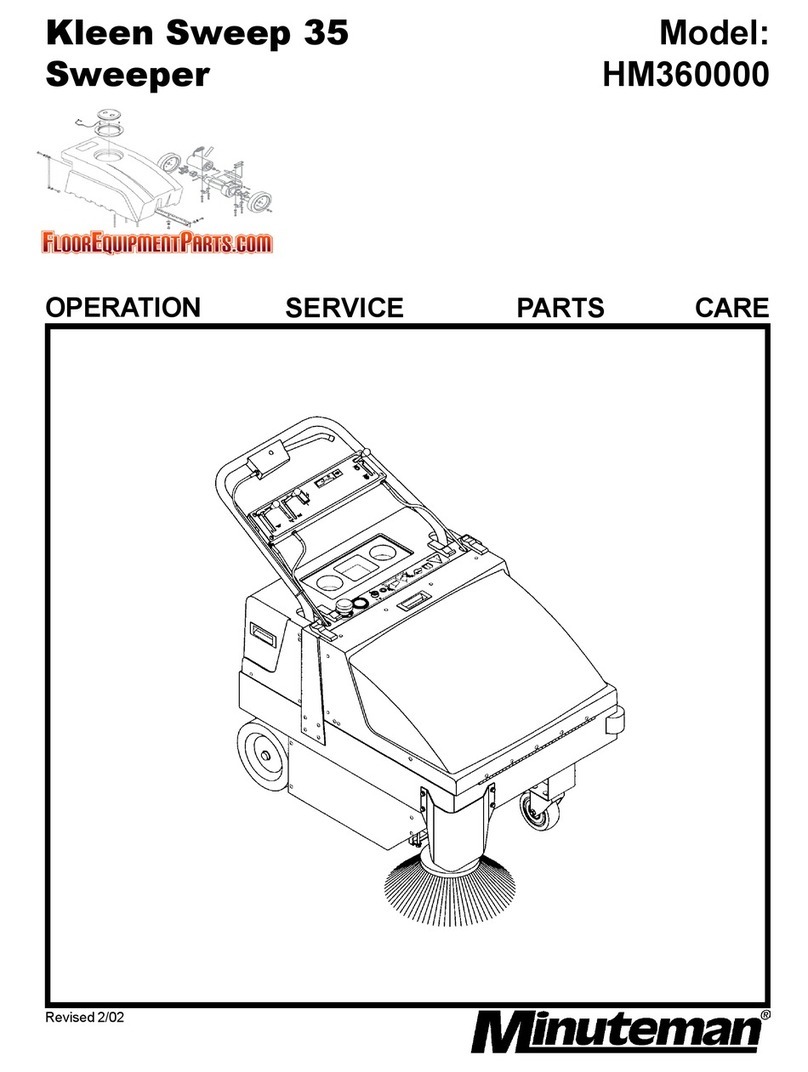

KLEEN SWEEP 35W – HOW IT WORKS..........................................................................8

ASSEMBLY ..................................................................................................................8

INSTALLING / SERVICING THE BATTERIES.......................................................................8

OPERATION OF THE KLEEN SWEEP 35W .......................................................................9

CONTROLS........................................................................................................ 10

HOW TO USE THE KLEEN SWEEP 35W........................................................................11

SWEEPING WITH THE KLEEN SWEEP 35W....................................................................11

EMPTY DIRT HOPPER.................................................................................................12

TRACTION DRIVE.......................................................................................................12

REPLACE BROOM ROLLER..........................................................................................12

ADJUST SWEEPING TRACK.........................................................................................13

REPLACING THE SIDE BROOM.....................................................................................13

REPLACING THE SIDE BROOM V-BELT.........................................................................14

FILTER SYSTEM – DUST EXTRACTOR ..........................................................................14

MAINTENANCE................................................................................................. 16

EXPLODED VIEWS ........................ FEHLER! TEXTMARKE NICHT DEFINIERT.

TRACTION DRIVE...............................................FEHLER! TEXTMARKE NICHT DEFINIERT.9

TRAVEL DRIVE ..........................................................................................................23

CHASSIS - COVERING ................................................................................................25

STEERING HANDLE ....................................................................................................29

SWEEP ROLLER WITH TRAVEL DRIVE ..........................................................................31

FILTER INSTALLATION.................................................................................................35

LIFTER HOPPER ........................................................................................................37

SIDE BRUSH DRIVE....................................................................................................39

CIRCUIT DIAGRAM........................................................................................... 40

WIRING DIAGRAM............................................................................................ 41

LIMITED WARANTY.......................................................................................... 42