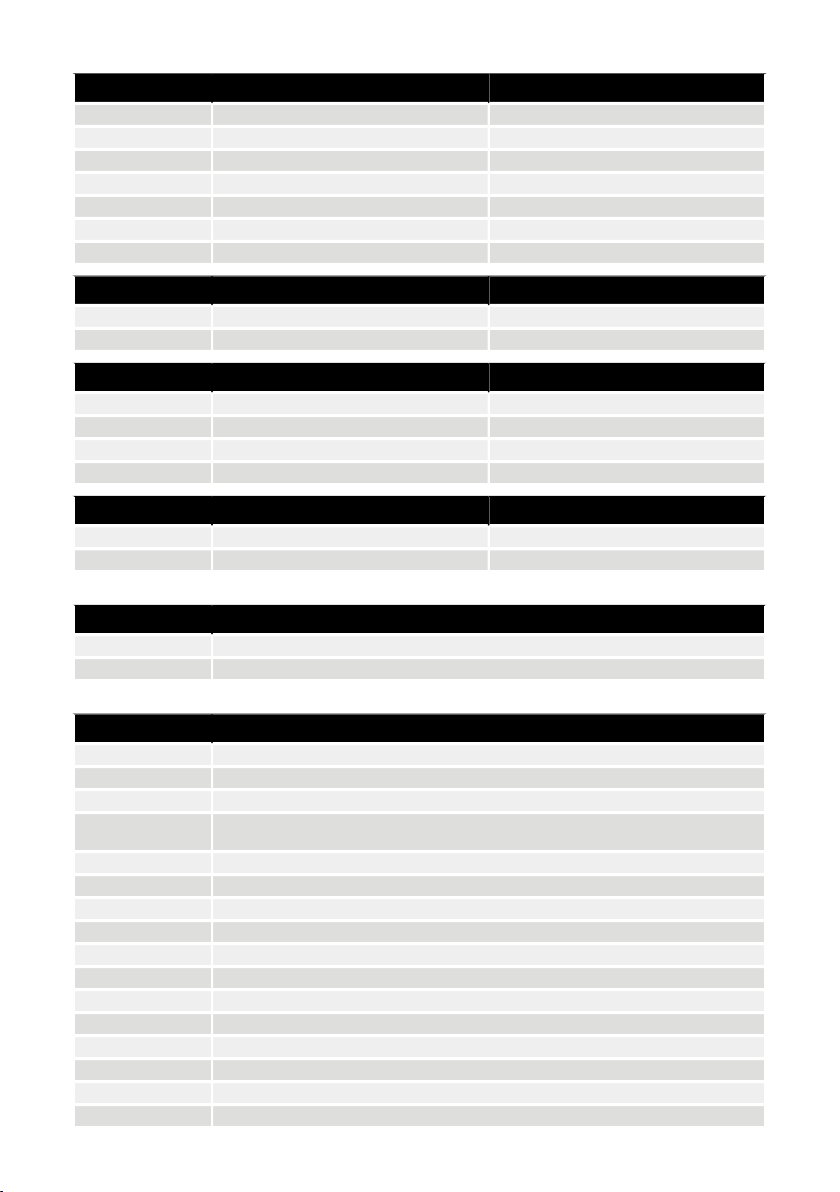

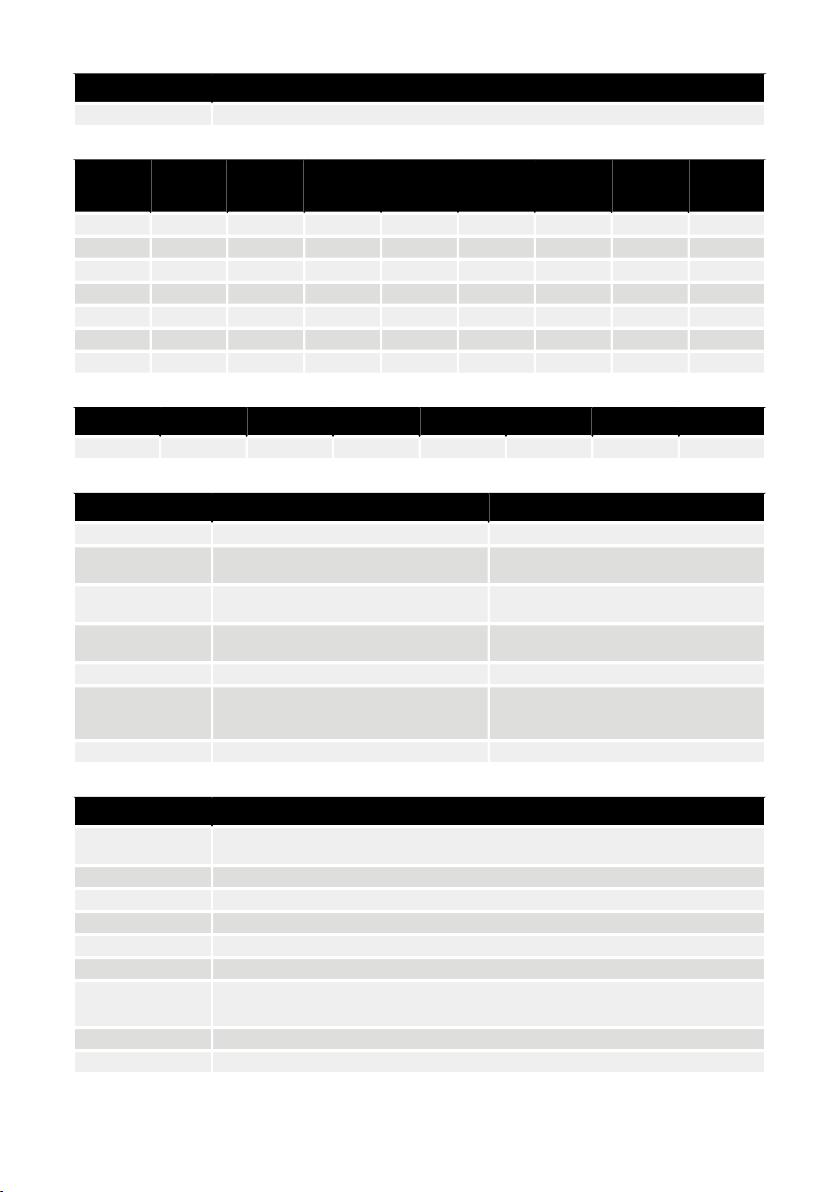

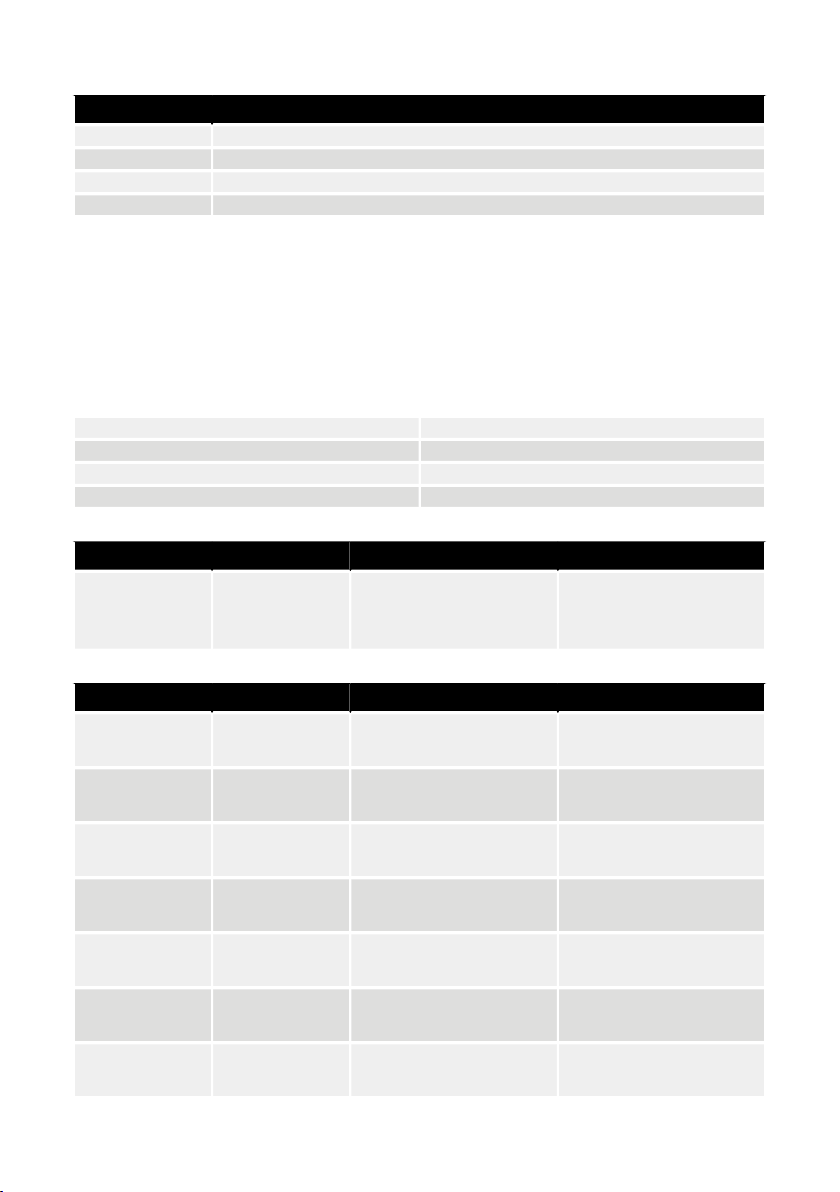

Hilscher NT 50-RS-EN adapter cable pinout (female DSUB-9)

DescriptionPIN (colour)

GND1 (white, WH)

Modbus RTU (A, RxD / TxD+)4 (brown, BN)

Modbus RTU (B, RxD / TxD–)5 (green, GN)

ShieldSHIELD

Modbus RTU

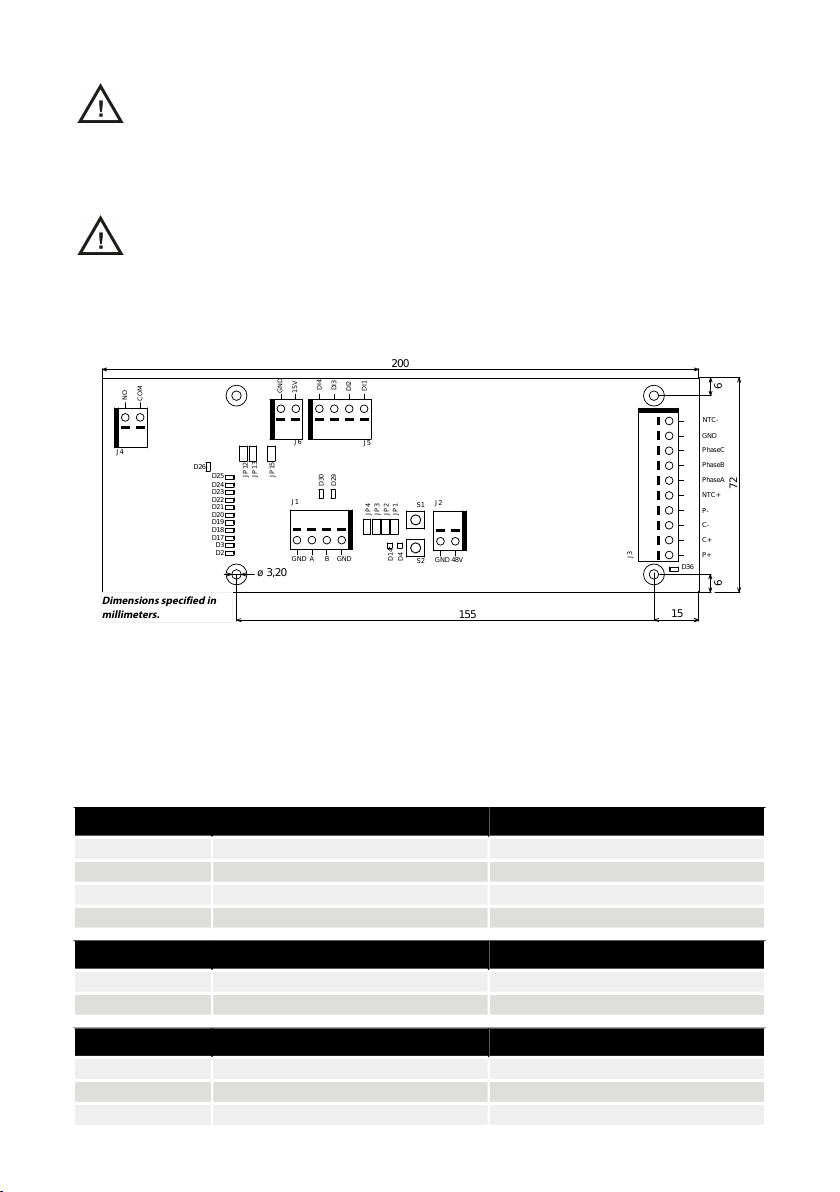

Modbus RTU over RS-485 is used to communicate with the motor drive. The motor drive is configured as a Modbus RTU

slave device and the default slave address is 86. The slave address can be changed if it conflicts with another Modbus

RTU slave device.

The J1 connector on the motor drive is used for Modbus RTU communication. A shielded twisted pair cable is recommended

and the shield should be earthed only at one point, normally at the master device. The A-pin of the J1 connector is

equivalent to RxD / TxD+ and the B-pin is equivalent to RxD / TxD–.

RS-485 configuration

19200BAUD RATE

EVENPARITY

1STOP BITS

8DATA BITS

Coil registers (F1, F5, F15)

DesciptionNameData typeAddress

Coils 1–11 are reserved for future

use.

Digital outputsUint1600001 - 00012

Coil 12 is the relay located on the

motor drive.

Input registers (F4)

DescriptionNameData typeAdress

The number of times the speed

has dropped from set-point by

more than 25%.

Drop RPM countUint1630001

The number of times the tool

temperature has exceeded the

“warm”limit, 79°C.

Warm tool countUint1630002

The number of times the motor

drive temperature has exceeded

the “warm”limit, 73°C.

Warm motor drive countUint1630003

The number of times the tool

temperature has exceeded the

“hot”limit, 134°C.

Hot tool countUint1630004

The number of times the motor

drive temperature has exceeded

the “hot”limit, 117°C.

Hot motor drive countUint1630005

The number of times the tool

temperature has exceeded the

“stop”limit, 142°C.

Stop tool countUint1630006

The number of times the motor

drive temperature has exceeded

the “stop”limit, 123°C.

Stop motor drive countUint1630007

9

en (original)