CONTENTS

1 Overview..................................................................................................................................................................2

1.1 Technical Parameters................................................................................................................................. 2

1.2 Functions &Features...................................................................................................................................2

1.3 Working Principle.........................................................................................................................................3

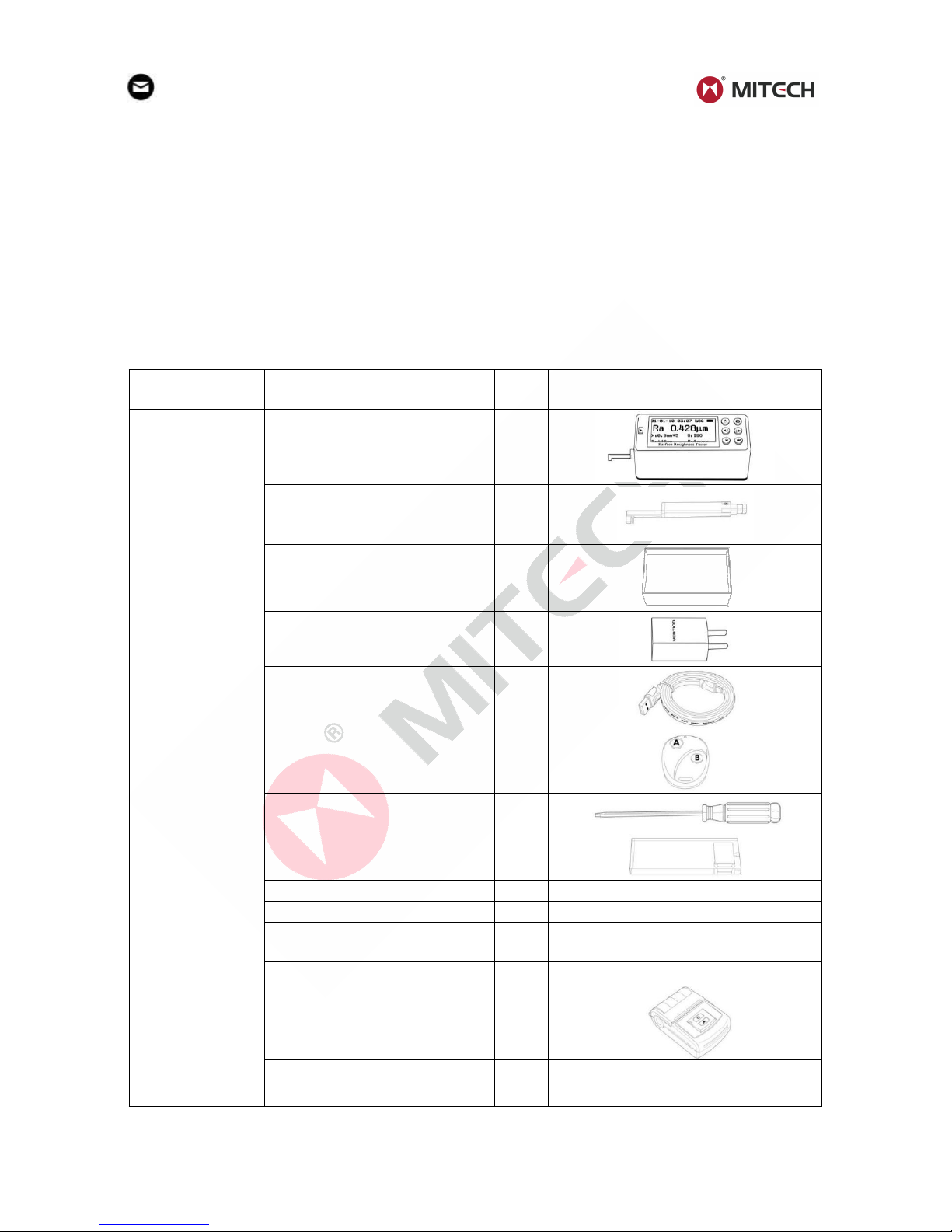

1.4 Instrument Configuration............................................................................................................................3

1.5 Working Conditions..................................................................................................................................... 4

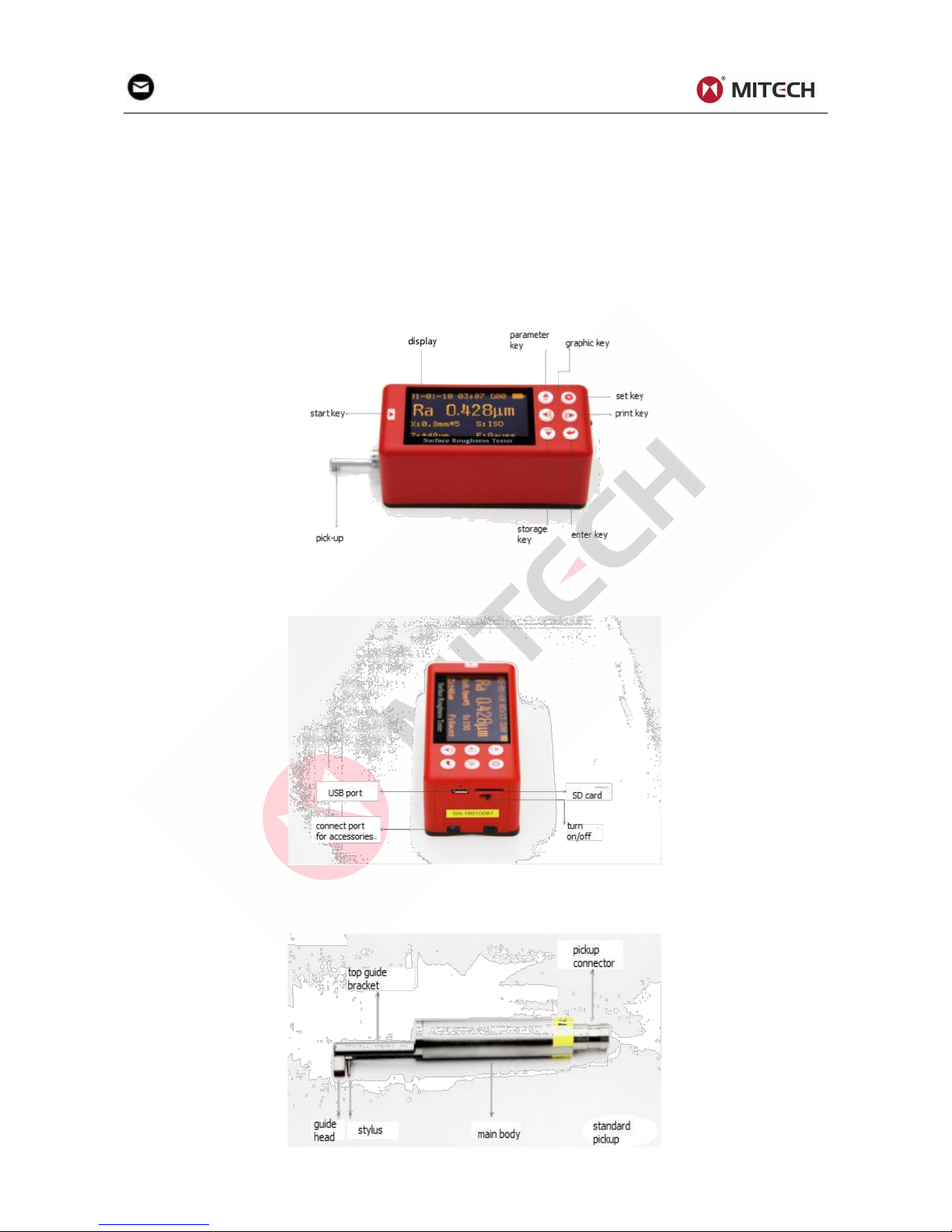

2 Structure and Outline.......................................................................................................................................... 4

2.1 Main Body Structure................................................................................................................................... 4

2.2 Probe Structure............................................................................................................................................4

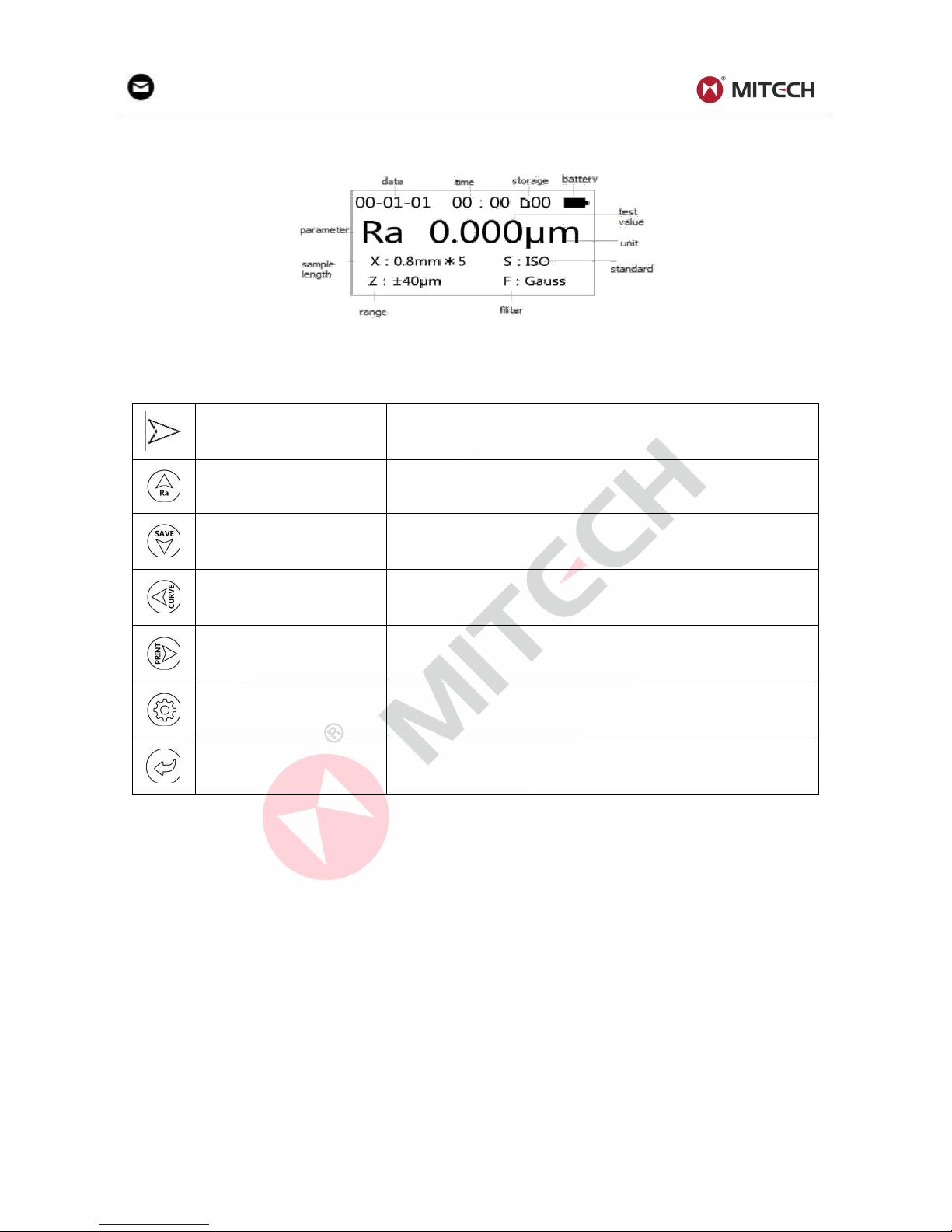

2.3 Display...........................................................................................................................................................5

2.4 Keypad Definitions...................................................................................................................................... 5

3. Operation............................................................................................................................................................... 5

3.1 Connecting Probe........................................................................................................................................5

3.2 Power On/Off................................................................................................................................................5

3.3 Battery Charging..........................................................................................................................................6

3.4 Parameter Setting........................................................................................................................................6

3.5 Preparation Before Measurement............................................................................................................ 7

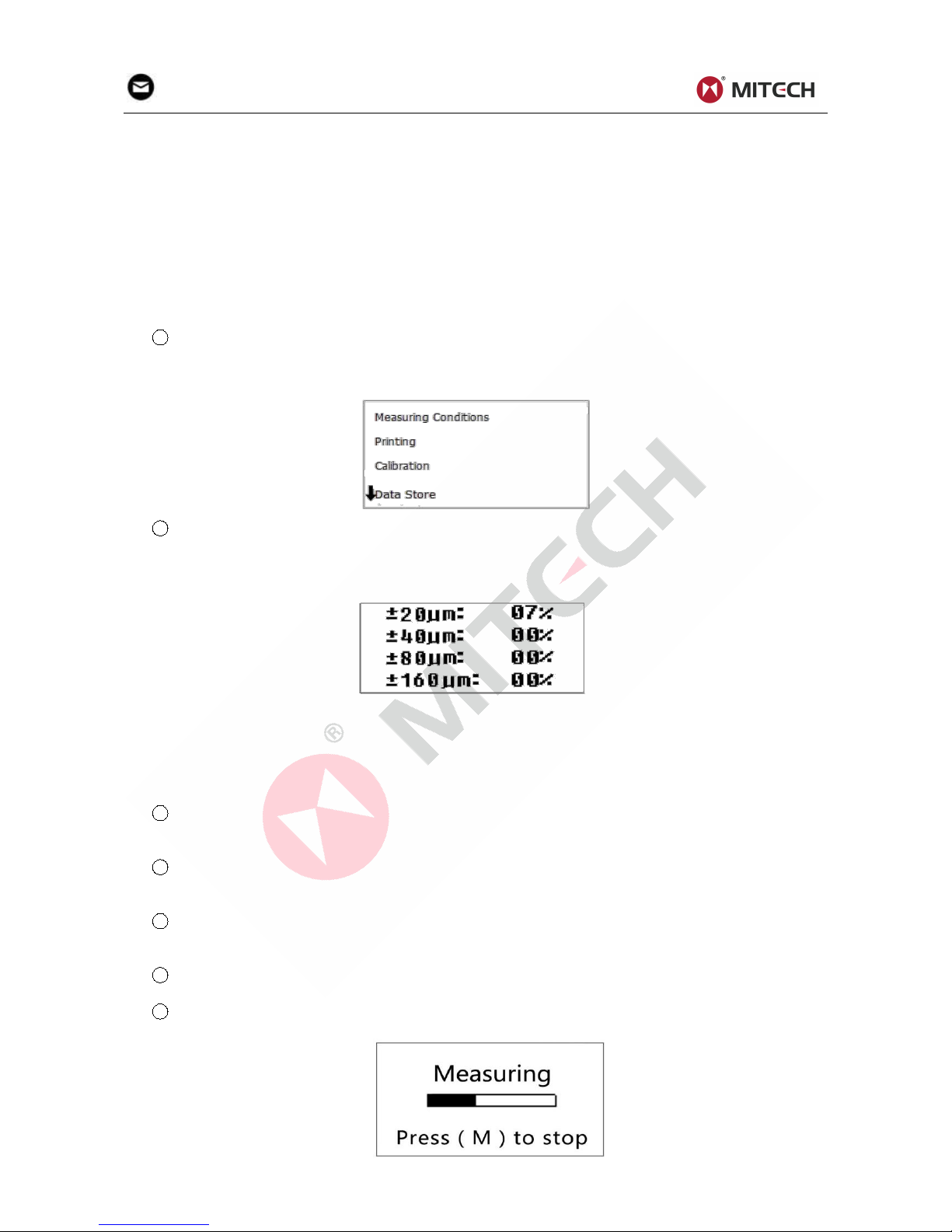

3.6 Start Measurement......................................................................................................................................8

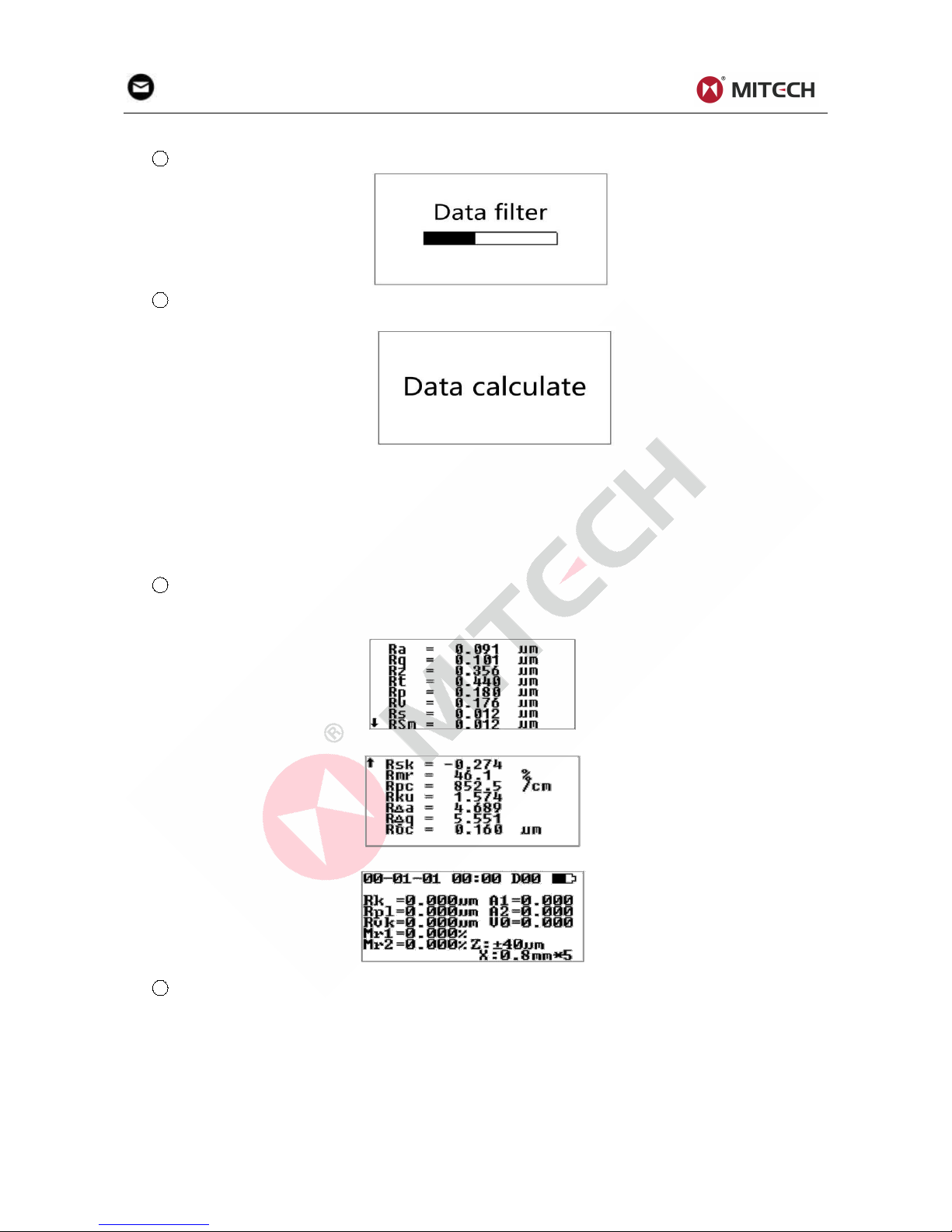

3.7 Display Readings.........................................................................................................................................9

3.8 Save/Read Measurement Results..........................................................................................................10

3.9 Print Measurement Results..................................................................................................................... 10

3.10 Communication With PC........................................................................................................................11

3.11 Remote Control and Measurement...................................................................................................... 12

3.12 SD Card Instructions...............................................................................................................................12

4 Software Information......................................................................................................................................... 12

5 Maintenance......................................................................................................................................................... 12

5.1 Probe........................................................................................................................................................... 12

5.2 Main Unit.....................................................................................................................................................12

5.3 Battery......................................................................................................................................................... 12

5.4 Calibration Specimen................................................................................................................................12

5.5 Maintenance Notice.................................................................................................................................. 12

6 Troubleshooting..................................................................................................................................................13

7 Optional Accessories........................................................................................................................................ 13

7.1 Height Support & Probe Sheath............................................................................................................. 13

Height Support and Probe Sheath................................................................................................................ 13

7.2 Height Lifting Pillar.................................................................................................................................... 13

7.3 Standard Probe..........................................................................................................................................14

7.4 Curved Surface Probe.............................................................................................................................. 14

7.5 Deep Groove Probe.................................................................................................................................. 15

7.6 Small Hole Probe.......................................................................................................................................16

7.7 Extension Bar.............................................................................................................................................17

8 References............................................................................................................................................................17

8.1Terms............................................................................................................................................................ 17

8.2 Traversing Length of Filters..................................................................................................................... 17

8.3 Parameters Definitions............................................................................................................................. 18

8.4 Recommended Table of Sampling Length............................................................................................ 20

Appendix.................................................................................................................................................................. 21

Appendix I: Standard Code and Name Table..............................................................................................21

Appendix II: Roughness Parameters Display Range.................................................................................21

User Notes................................................................................................................................................................22