CONTENTS

1 Overview................................................................................................................................................................. 3

1.1 Advantages................................................................................................................................................ 3

1.2 Main Application &Testing Range.......................................................................................................... 3

1.2.1 Main Application.....................................................................................................................................3

1.2.2 Testing Range.........................................................................................................................................3

1.3 Technical Specifications...........................................................................................................................4

1.4 Configuration............................................................................................................................................. 4

1.5 Working Conditions...................................................................................................................................5

1.6 Safety Instructions.................................................................................................................................... 5

2 Structure Feature &Testing Principle............................................................................................................. 5

2.1 Structure Feature...................................................................................................................................... 5

2.1.1 The Hardness Tester Appearance...................................................................................................... 5

2.1.2 Parts of the Main body.......................................................................................................................... 6

2.1.3 D Type Impact Device...........................................................................................................................7

2.1.4 Different Types of Impact Device........................................................................................................7

2.2 Main Screen...............................................................................................................................................7

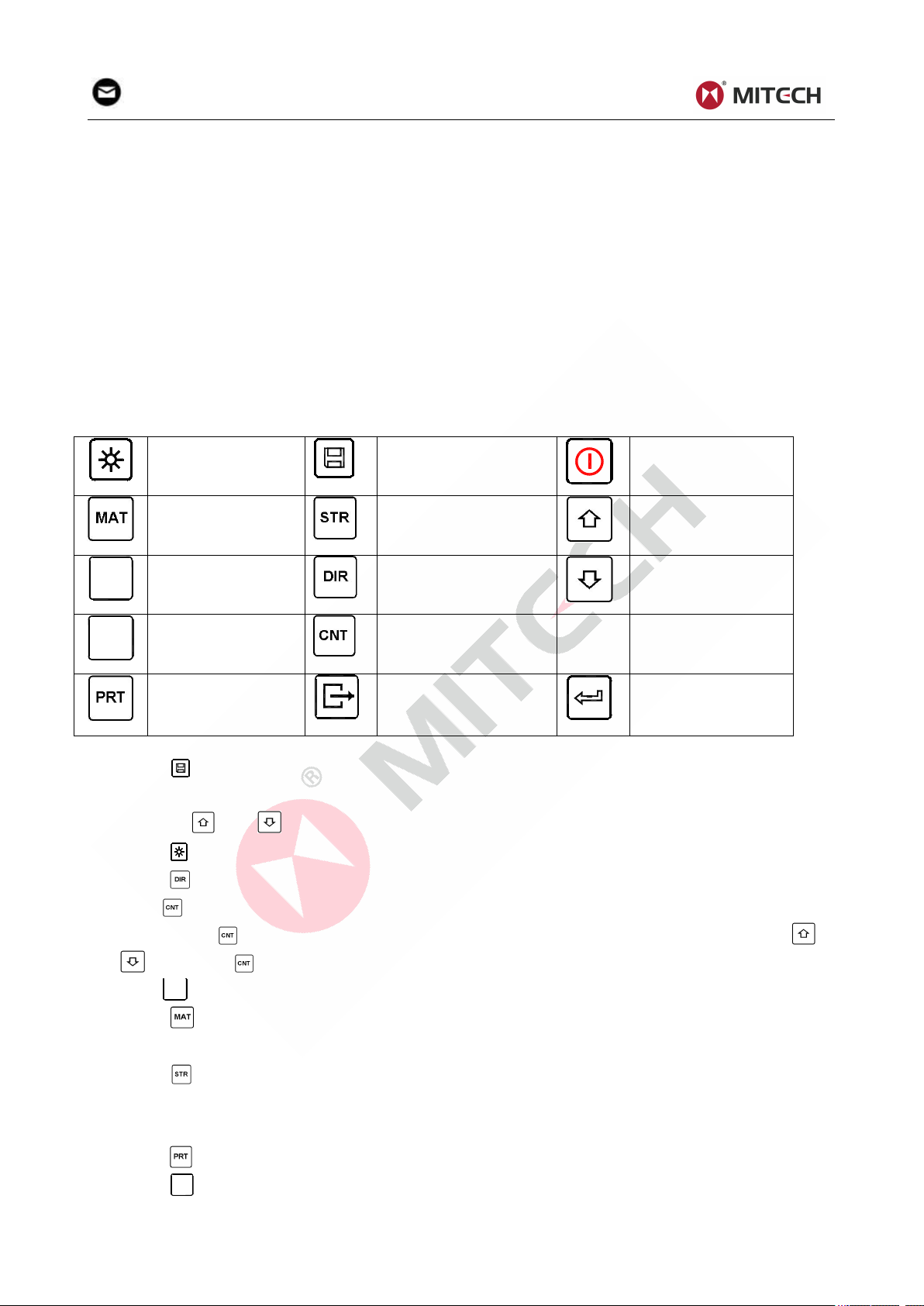

2.3 Keypad Definitions....................................................................................................................................8

2.4 Leeb Hardness Testing Principle............................................................................................................9

3 Preparation.............................................................................................................................................................9

3.1 Instrument Preparation and Inspection................................................................................................. 9

3.2 Impact Device Selection.......................................................................................................................... 9

3.3 Preparation of the Sample Surface........................................................................................................9

4 Testing Program................................................................................................................................................. 10

4.1 Start-Up.................................................................................................................................................... 10

4.3 Localization.............................................................................................................................................. 10

4.4 Testing.......................................................................................................................................................10

4.5 Read Measured Value............................................................................................................................11

4.6 Notification................................................................................................................................................11

5 Operation Detail.................................................................................................................................................. 11

5.1 Power On/Off........................................................................................................................................... 11

5.2 Material Setting....................................................................................................................................... 12

5.3 Hardness/Strength testing.....................................................................................................................12

5.4 Impact Direction Setting........................................................................................................................ 12

5.5 Average Times Setting...........................................................................................................................12

5.6 Data logging.............................................................................................................................................12

5.6.1 Viewing stored file/Group...................................................................................................................13

5.6.2 Deleting selected file/Group.............................................................................................................. 13

5.7 Print Function.......................................................................................................................................... 13

5.7.2Print the stored data.............................................................................................................................13

5.8 Date and Time Set..................................................................................................................................14

5.9 System Reset.......................................................................................................................................... 14

5.10 EL Backlight...........................................................................................................................................14

5.11 Auto Power Off...................................................................................................................................... 14

5.12 Paper Installation..................................................................................................................................14

5.13 Battery Charge......................................................................................................................................14

5.14 Battery Replacement........................................................................................................................... 15

5.15 Connecting to a Computer..................................................................................................................15

5.16 Error Code Reference..........................................................................................................................15

6 Maintenance & Servicing................................................................................................................................. 15

6.1 Impact Device Maintenance................................................................................................................. 15

6.2 Instrument Maintenance Program....................................................................................................... 15

6.3 Fault Analysis & Evacuation................................................................................................................. 16

6.4 Notice of Transport and Storage Conditions......................................................................................16

APPENDIX................................................................................................................................................................17

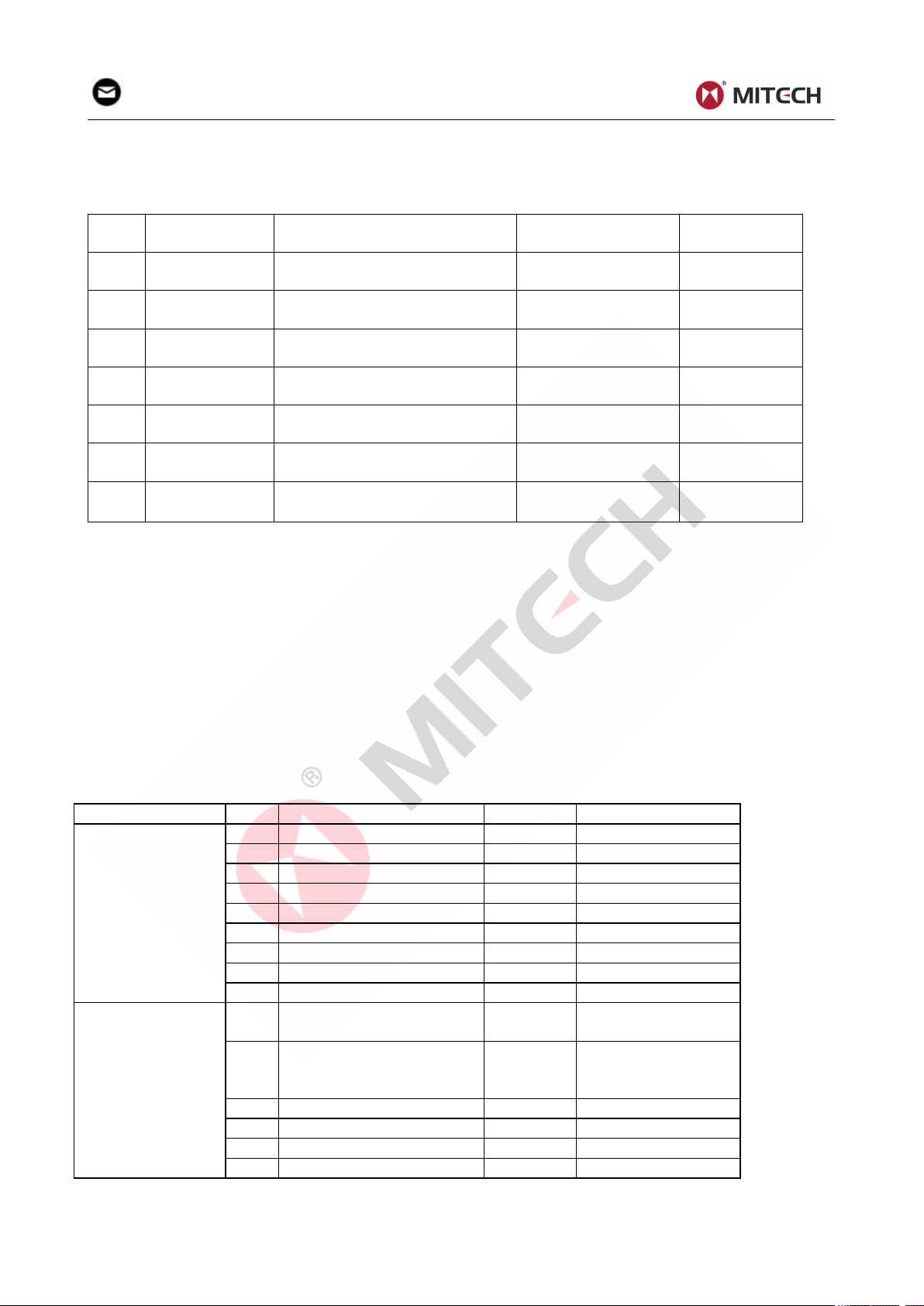

Table 1............................................................................................................................................................. 17

Table 2............................................................................................................................................................. 18