CONTENTS

1 Overview................................................................................................................................................................. 3

1.1 Advantages...................................................................................................................................................3

1.2 Main Application &Testing Range.............................................................................................................3

1.2.1 Main Application....................................................................................................................................... 3

1.2.2 Testing Range...........................................................................................................................................3

1.3 Configuration................................................................................................................................................4

1.4 Working Conditions.....................................................................................................................................4

1.5 Safety Instructions.......................................................................................................................................4

2 Structure Feature &Testing Principle............................................................................................................. 5

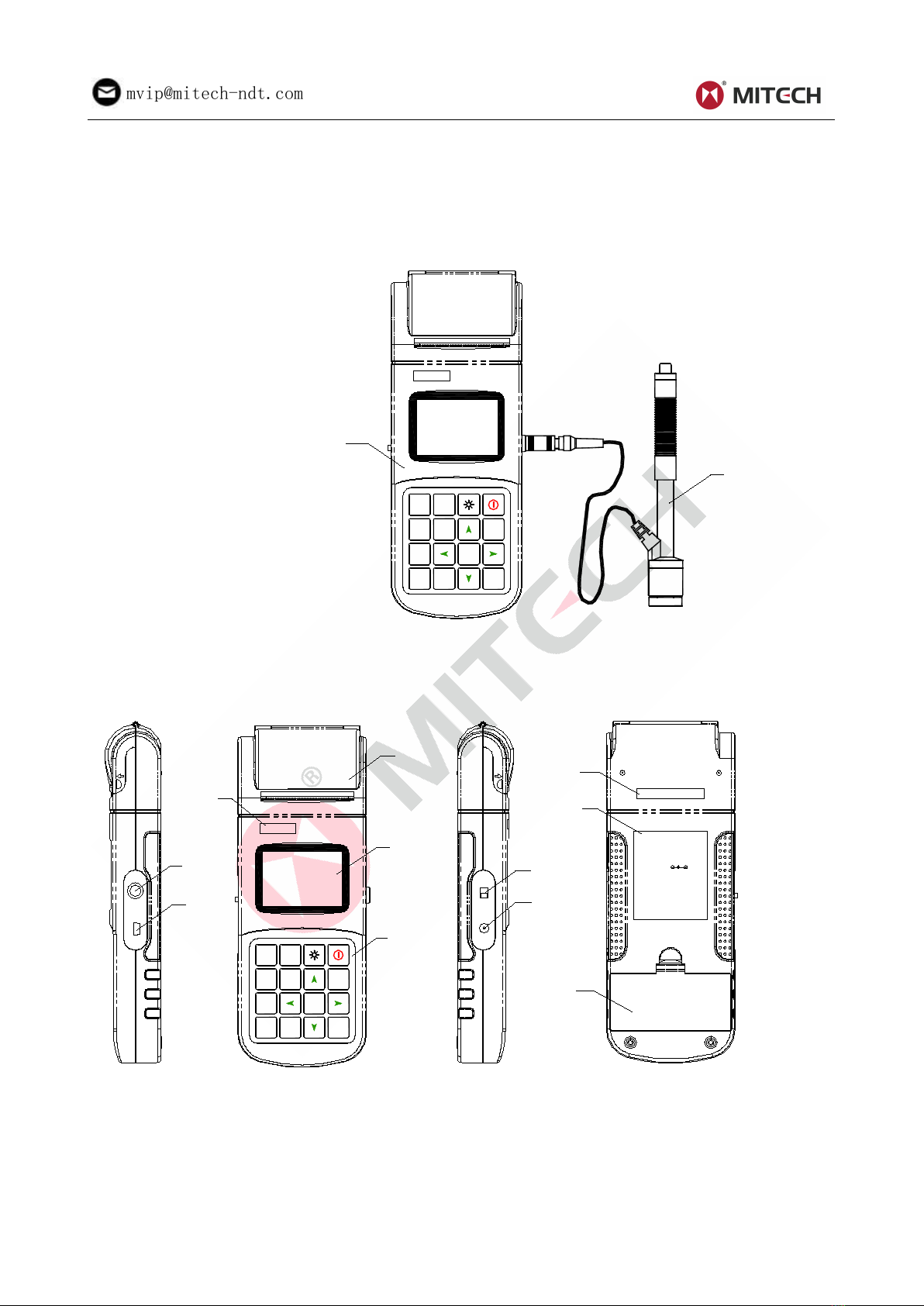

2.1 Structure Feature........................................................................................................................................ 5

2.1.1 The Hardness Tester Appearance........................................................................................................ 5

2.1.2 Parts of the Main body............................................................................................................................ 5

2.1.3 D Type Impact Device............................................................................................................................. 6

2.1.4 Different Types of Impact Device.......................................................................................................... 6

2.2 Leeb Hardness Testing Principle..............................................................................................................6

3 Technical Specifications.................................................................................................................................... 6

4 Preparation & Testing..........................................................................................................................................8

4.1 Preparation & Inspection before Testing................................................................................................. 8

4.1.1Preparation of Sample Surface.............................................................................................................. 8

4.1.2 System Setting......................................................................................................................................... 8

4.1.3Presetting Testing condition.................................................................................................................... 8

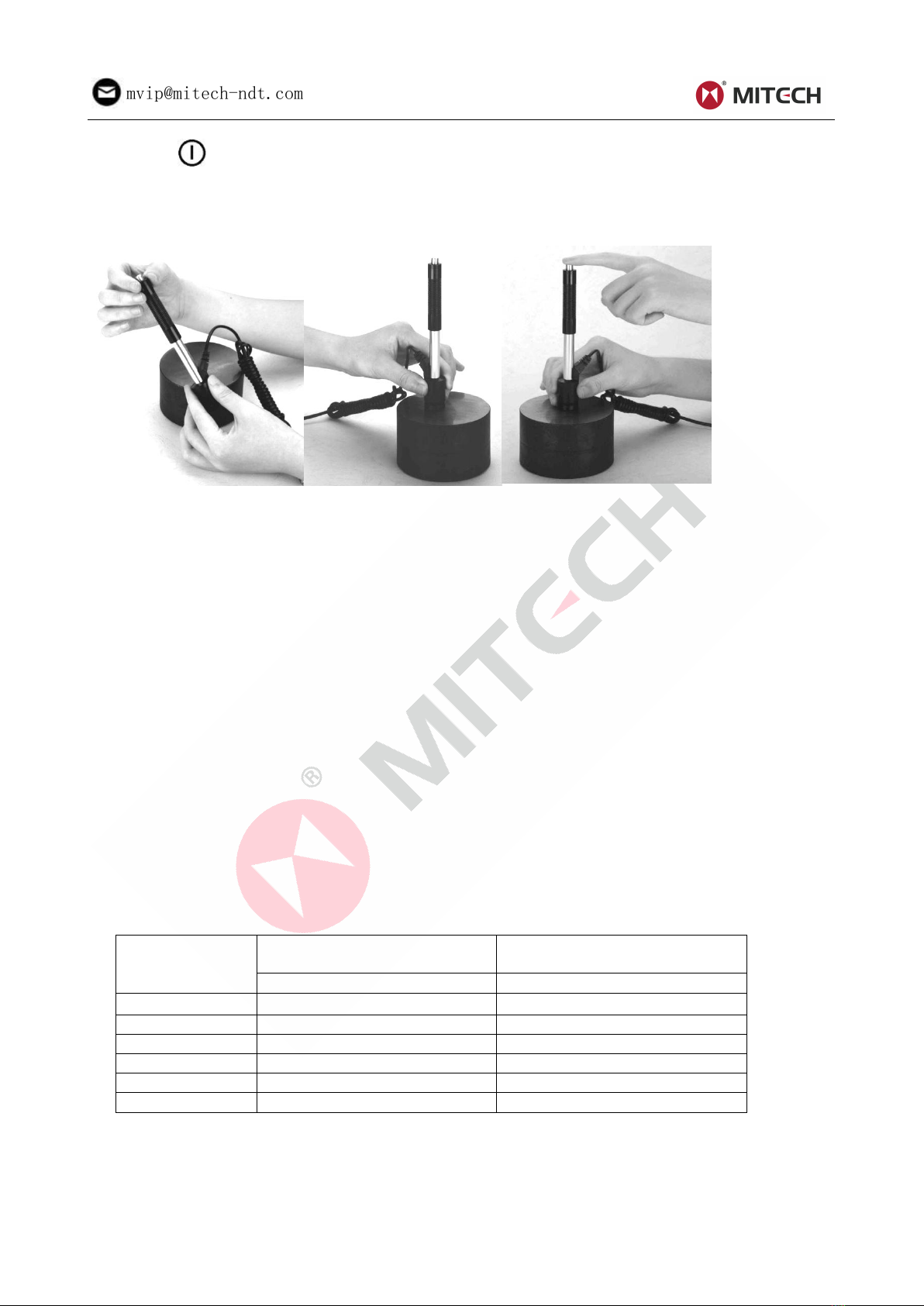

4.2 Testing Program.......................................................................................................................................... 8

4.2.1 Start-Up..................................................................................................................................................... 8

4.2.2 Loading...................................................................................................................................................... 9

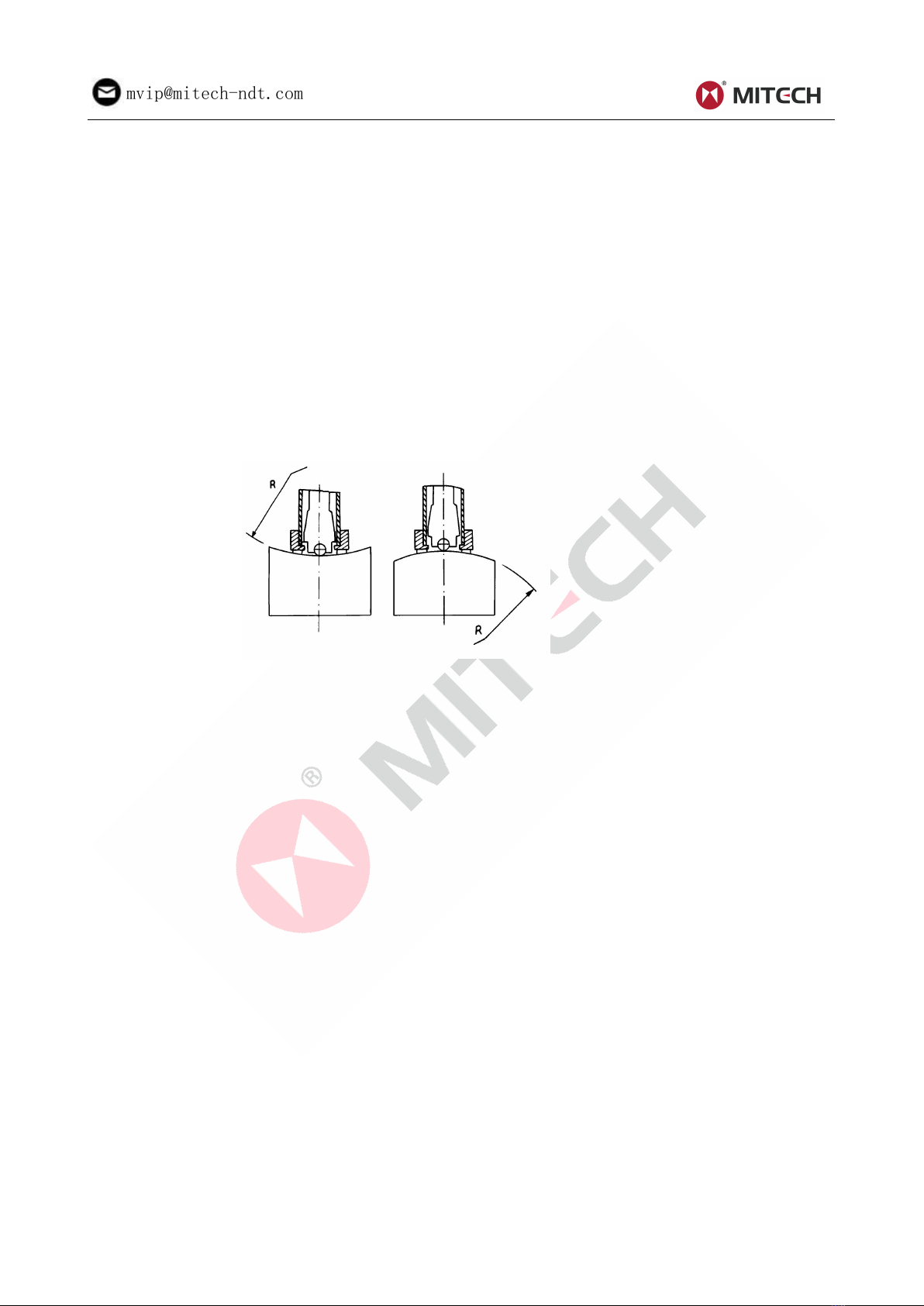

4.2.3 Localization............................................................................................................................................... 9

4.2.4 Testing........................................................................................................................................................9

4.2.5 Read measured value.............................................................................................................................9

4.2.6 Power Off................................................................................................................................................ 10

5 Advice....................................................................................................................................................................10

6 Operation in Details...........................................................................................................................................10

6.1 Power On....................................................................................................................................................10

6.2 Power Off....................................................................................................................................................10

6.3 Testing.........................................................................................................................................................10

6.3.1 Instruction of the Main Display Interface............................................................................................11

6.3.2 Testing Operation at the Main Display Interface...............................................................................11

6.3.3 Key Operation at the Main Display Interface.................................................................................... 11

6.4 Menu Structure.......................................................................................................................................... 11

6.5 Test Set....................................................................................................................................................... 13

6.6 Print Function.............................................................................................................................................15

6.7.Memory Manager......................................................................................................................................15

6.8 Browsing Memory Data Groups............................................................................................................. 17

6.9 System Set.................................................................................................................................................18

6.10 Software Information.............................................................................................................................. 19

6.11 System Calibration..................................................................................................................................19

6.12 EL Background Light..............................................................................................................................20

6.13 Auto Power Off........................................................................................................................................ 20

6.14 Paper Loading......................................................................................................................................... 20

6.15 Battery Charge........................................................................................................................................ 20

6.16 Battery Replacement..............................................................................................................................21

6.17 Connection of Data Transmission Cable............................................................................................ 21

7 Fault Analysis & Evacuation........................................................................................................................... 21

8 Servicing & Maintenance................................................................................................................................. 21

8.1 Impact Device Servicing.......................................................................................................................... 21

8.2 Normal Maintenance Program................................................................................................................21

9 Calibration............................................................................................................................................................21

10 Notice of Transport and Storage Conditions........................................................................................... 21