MEES21K047

PQRY-P-Z(S)LMU-A1

8

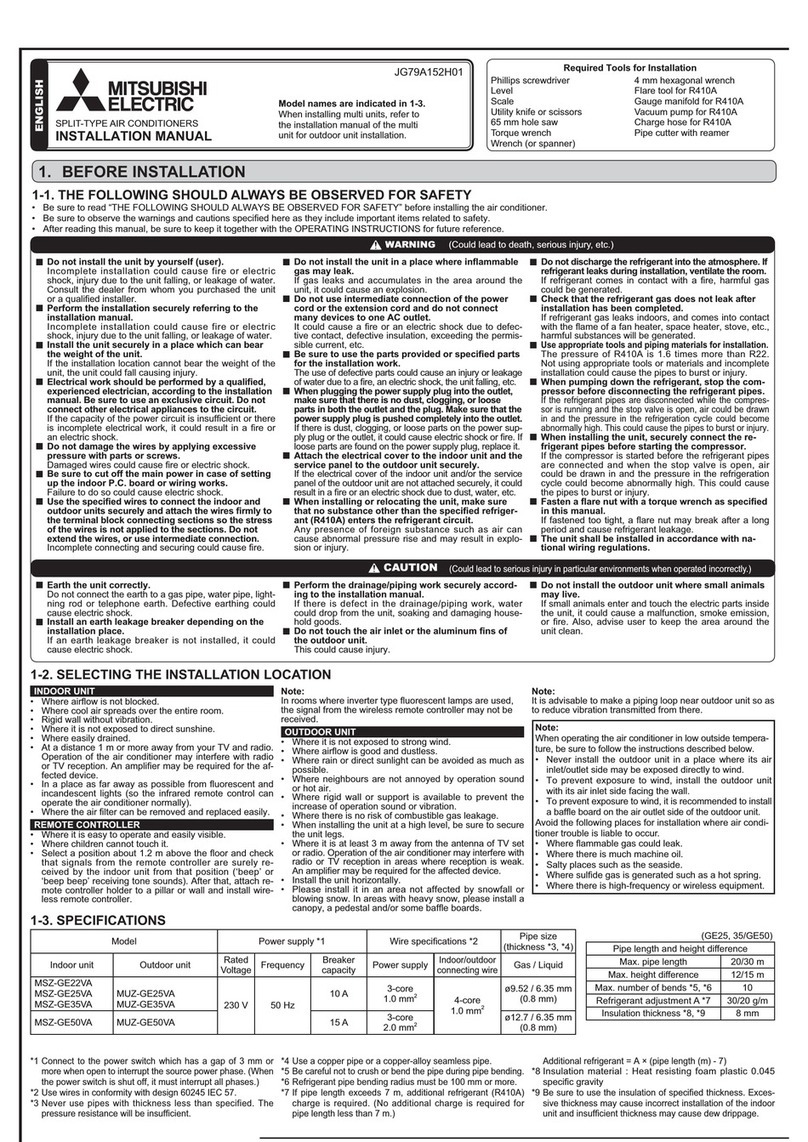

1. SPECIFICATIONS WR2-Series-575V

Heat Source Model PQRY-P144ZSLMU-A1

Indoor Model Non-Ducted Ducted

Power source 3-phase 3-wire 575 V ±10% 60 Hz

Cooling capacity *1 BTU/h 144,000

(Nominal) kW 42.2

Power input kW 7.11

(575) Current input A 7.9

(Rated) BTU/h 137,000

kW 40.2

Power input kW 6.53 7.72

(575) Current input A 7.2 8.6

Temp. range of Indoor W.B. 59~75°F (15~24°C)

cooling Inlet water ºF 50~113°F (10~45°C)

Heating capacity *2 BTU/h 160,000

(Nominal) kW 46.9

Power input kW 7.45

(575) Current input A 8.3

(Rated) BTU/h 152,000

kW 44.5

Power input kW 6.86 7.22

(575) Current input A 7.6 8.0

Temp. range of Indoor D.B. 59~81°F (15~27°C)

heating Inlet water ºF 50~113°F (10~45°C)

Indoor unit Total capacity 50~150% of heat source unit capacity

connectable Model/Quantity P04~P96/1~36

Sound pressure level (measured in anechoic room) dB <A> 49.0

Refrigerant High pressure in. (mm) 7/8 (22.2) Brazed

piping diameter Low pressure in. (mm) 1-1/8 (28.58) Brazed

Set Model

Model PQRY-P72ZLMU-A1 PQRY-P72ZLMU-A1

Minimum Circuit Ampacity A 5 5

Maximum Overcurrent Protection A 15 15

Circulating water Water flow rate G/h 1,522 + 1,522

G/min (gpm) 25.4 + 25.4

m3/h 5.76 + 5.76

L/min 96 + 96

cfm 3.4 + 3.4

Pressure drop psi 3.48 3.48

kPa 24 24

Operating volume G/h 793 + 793 ~ 1,902 + 1,902

range G/min (gpm) 13.2 + 13.2 ~ 31.7 + 31.7

m3/h 3.0 + 3.0 ~ 7.2 + 7.2

Compressor Type x Quantity Inverter scroll hermetic compressor x 1 Inverter scroll hermetic compressor x 1

Starting method Inverter Inverter

Motor output kW 4.3 4.3

Case heater kW - -

Lubricant MEL32 MEL32

External finish Galvanized steel sheets Galvanized steel sheets

External dimension H x W x D in. 43-5/16 x 34-11/16 x 21-11/16 43-5/16 x 34-11/16 x 21-11/16

mm 1,100 x 880 x 550 1,100 x 880 x 550

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

Inverter circuit Over-heat protection, Over-current protection Over-heat protection, Over-current protection

Compressor Over-heat protection Over-heat protection

Refrigerant Type x original charge R410A x 11 lbs + 1 oz (5.0 kg) R410A x 11 lbs + 1 oz (5.0 kg)

Control Indoor LEV and BC controller

Net weight lbs (kg) 411 (186) 411 (186)

Heat exchanger plate type plate type

Water volume in plate G 1.32 1.32

l 5.0 5.0

Water pressure Max. psi 290 290

MPa 2.0 2.0

HIC circuit (HIC: Heat Inter-Changer) - -

Pipe between unit and High pressure in. (mm) 5/8 (15.88) Brazed 5/8 (15.88) Brazed

distributor Low pressure in. (mm) - 3/4 (19.05) Brazed

Drawing External KL94C251

Wiring KE94G421 KE94G421

Standard Document Installation Manual

attachment Accessory Details refer to External Drw

Optional parts Heat Source Twinning kit: CMY-Q100CBK2

joint: CMY-Y102SS-G2, CMY-Y102LS-G2, CMY-R160-J1

Main BC controller: CMB-P108,1012,1016NU-JA1, CMB-P1016NU-KA1

Sub BC controller: CMB-P104,108NU-KB1

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be re-

ferred to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the Heat Source Unit needs to be kept below 104°FD.B. (40°CD.B.)

The ambient relative humidity of the Heat Source Unit needs to be kept below 80%.

The Heat Source Unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

The Heat Source twinning kit (low pressure) should be connected to the low pressure side of the heat source unit.

Install the supplied insulation material to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

The cooling tower and the water circuit must be a closed circuit (water is not exposed to the atmosphere).

Notes: Unit converter

1.Nominal cooling conditions (Test conditions are based on AHRI 1230)

Indoor: 81°FD.B./66°FW.B. (27°CD.B./19°CW.B.), Inlet water temperature: 86°F (30°C)

2.Nominal heating conditions (Test conditions are based on AHRI 1230)

Indoor: 68°FD.B. (20°CD.B.), Inlet water temperature: 68°F (20°C)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

0000006382.BOOK 8 ページ 2021年7月19日 月曜日 午後4時14分