3

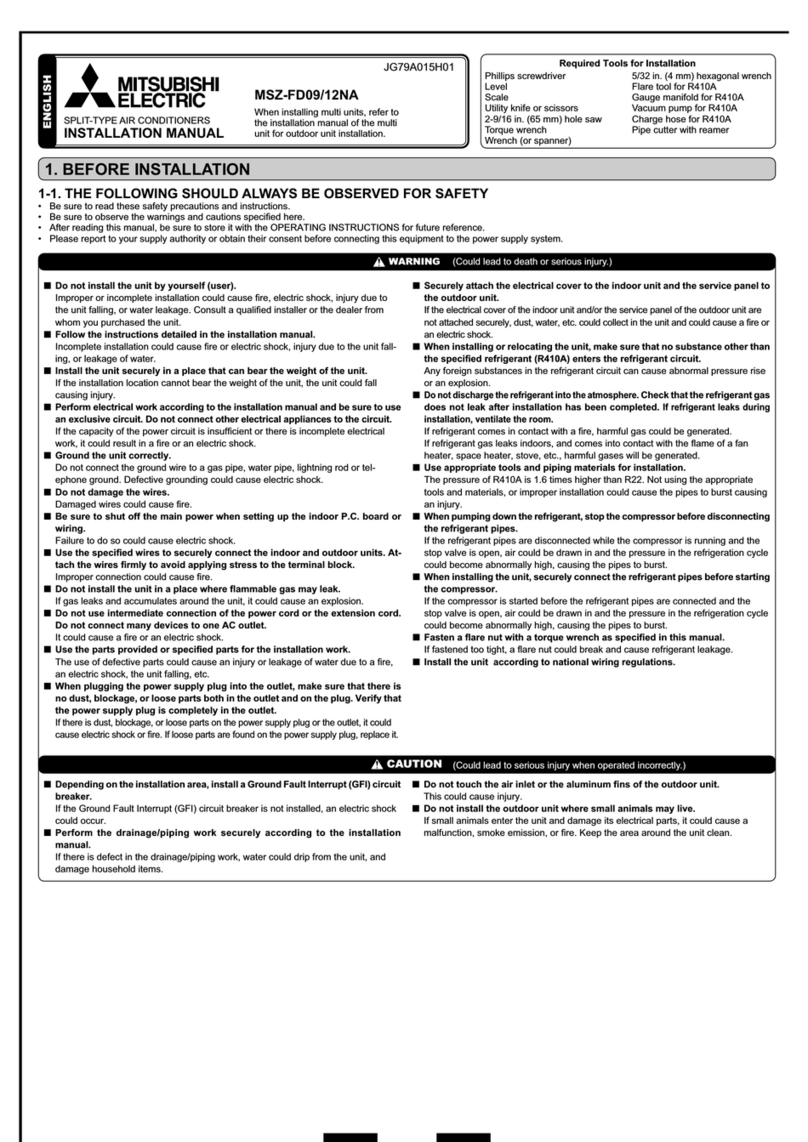

2SAFETY PRECAUTION

Precautions for devices that use R407C refriqerant.

Cautions for connecting with R407C outdoor unit.

.Caution:

· Do not use R407C piping after use it for R22.

· Do not use the existing refrigerant piping.

-The o d refrigerant and refrigerator oi in the existing piping contains a arge amount of ch orine which may cause the

refrigerator oi of the new unit to deteriorate.

· Use refrigerant piping made of C1220(CU-DHP) phosphorus deoxidized copper as specified in the JIS H3300

“Copper and copper alloy seamless pipes and tubes”. In addition, be sure that the inner and outer surfaces of the

pipes are clean and free of hazardous sulphur, oxides, dust/dirt, shaving particles, oils, moisture, or any other

contaminant.

-Contaminants on the inside of the refrigerant piping may cause the refrigerant residua oi to deteriorate.

· Store the piping to be used during installation indoors and keep both ends of the piping sealed until just before

brazing. (Store elbows and other joints in a plastic bag.)

-If dust, dirt, or water enters the refrigerant cyc e, deterioration of the oi and compressor troub e may resu t.

· Use ester oil, ether oil or alkylbenzene (small amount) as the refrigerator oil to coat flares and flange connections.

-The refrigerator oi with degrade if it is mixed with a arge amount of minera oi .

· Use liquid refrigerant to fill the system.

-If gas refrigerant is used to sea the system, the composition of the refrigerant in the cy inder wi change and performance

may drop.

· Do not use a refrigerant other than R407C.

-If another refrigerant (R22, etc.) is used, the ch orine in the refrigerant may cause the refrigerator oi to deteriorate.

· Use a vacuum pump with a reverse flow check valve. Evacuate sufficiently for one hour, leave it put for another one

hour and be sure not to down the vacuum degree.

· Do not use the following tools that are used with conventional refrigerants.

No. Too name Specifications

1Gauge manifo d ·On y for R407C.

·Use the existing fitting SPECIFICATIONS. (UNF7/16)

·Use high-tension side pressure of 35kgf/cm2or over.

2Charge hose ·On y for R407C.

·Use pressure performance of 52kgf/cm2or over.

3E ectronic sca e

4Gas eak detector ·Use the detector for R134a or R407C.

5Adapter for reverse f ow check. ·Attach on vacuum pump.

6Refrigerant charge base.

7Refrigerant cy inder. ·For R407C ·Top of cy inder (Brown)

·Cy inder with syphon

8Refrigerant recovery equipment.

· Do not use a charging cylinder.

-Using a charging cy inder may cause the refrigerator to deteriorate.

· Be especially careful when managing the tools.

-If dust, dirt, or water gets in the refrigerant cyc e, the refrigerant may deteriorate.

· For gas leak detecter, be sure to use it only for HFC refrigerant. (same as for R134a)

· If moving, put the cap on the flare at indoor unit side to prevent to mix dust or water.

· If measures on refrigerant leackage or repair servicing, be sure to refer the manual for outdoor unit.