E-2

Safety precautions

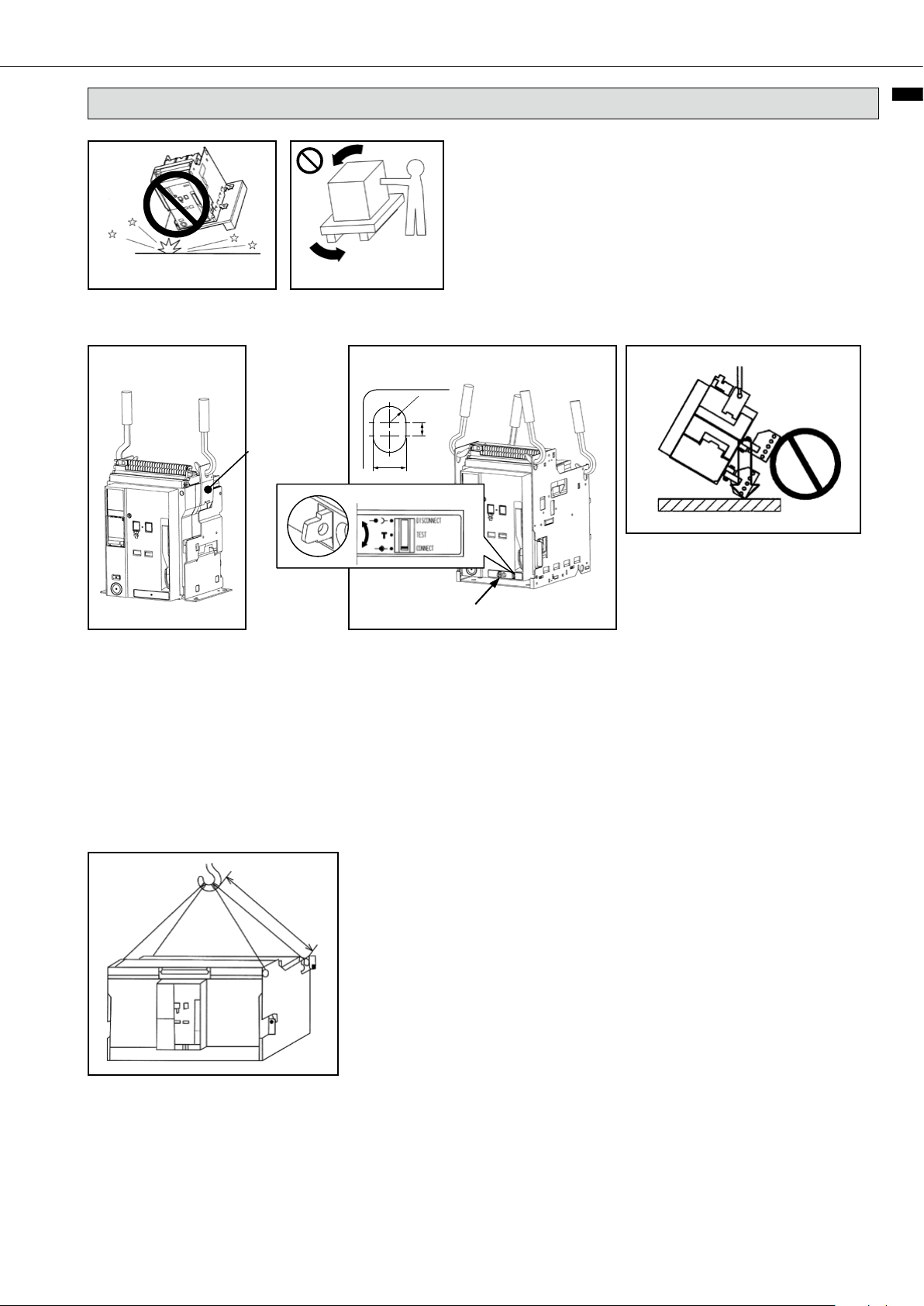

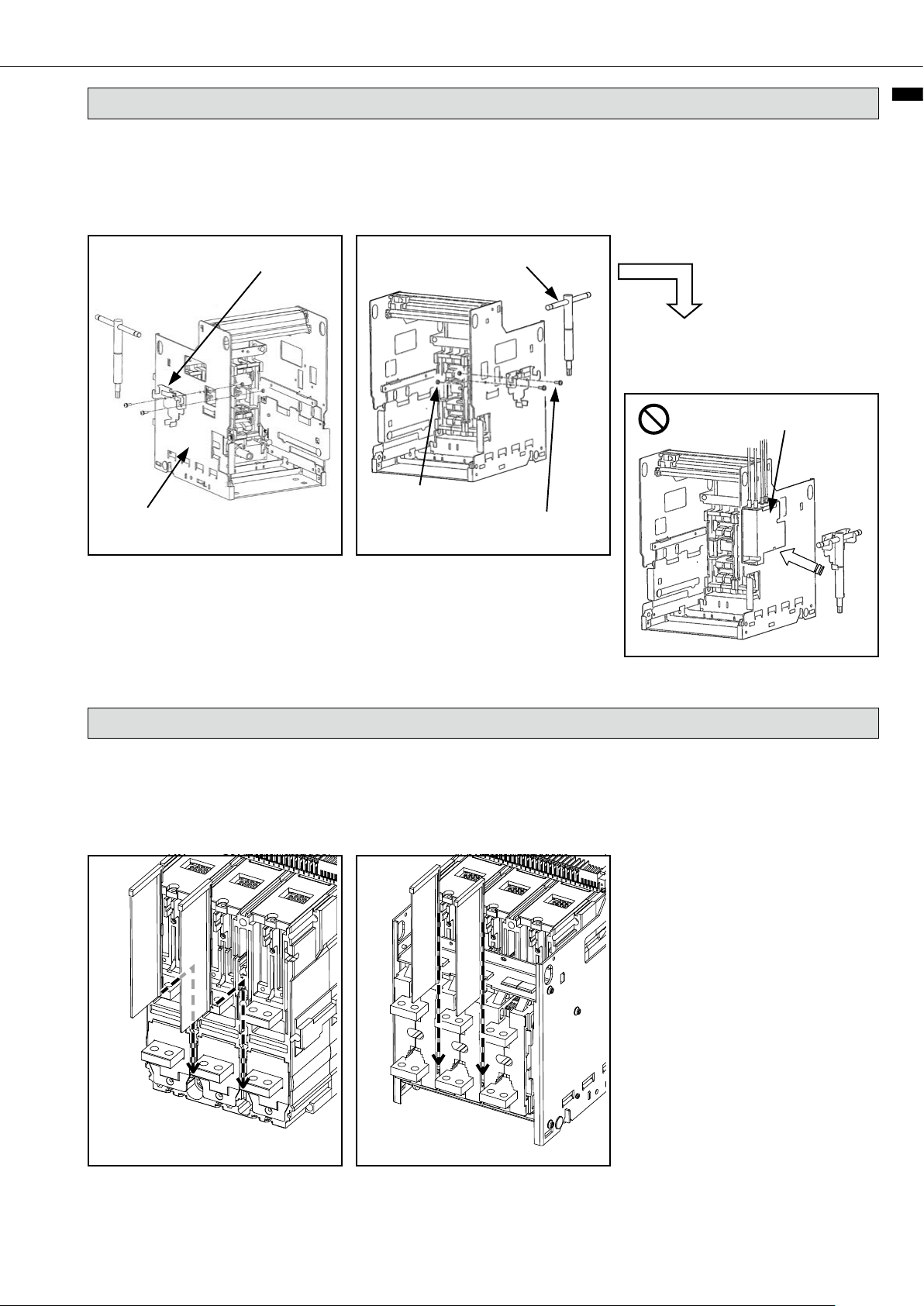

This means prohibition. Never ignore

this instruction.

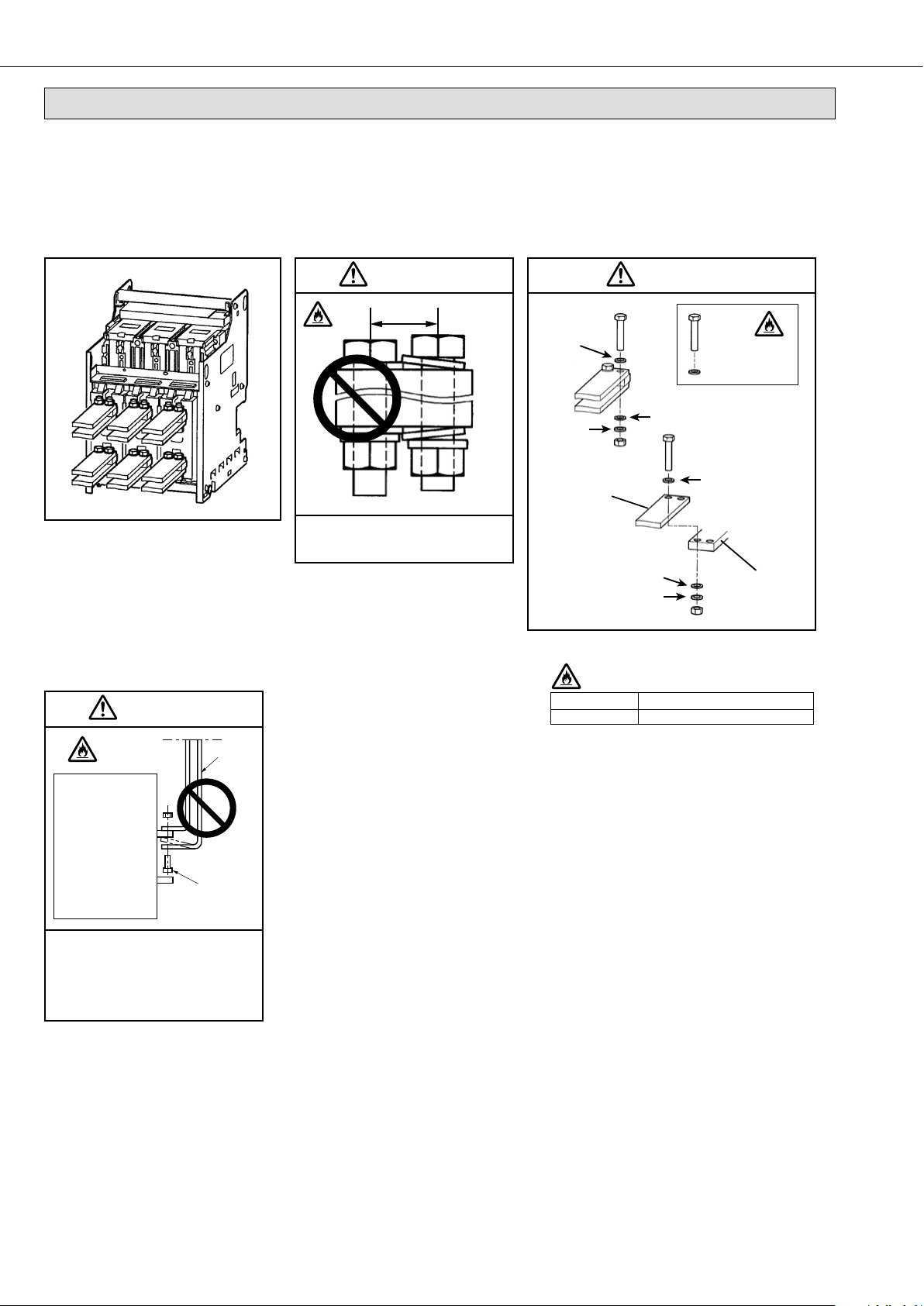

Warning for possible outbreak of a fire

under certain conditions.

Warning for possible electrical shock

under certain conditions.

Do not use the product under the conditions with over-rated current. Otherwise, ground-fault or short circuit fault

could occur due to dielectric breakdown, or explosion could occur due to a short circuit protection failure.

Do not touch terminal area. There is a risk of electrical shock.

Be sure to follow these instructions

without fail.

Before using this device, make sure to read this instruction manual thoroughly.

Important safety information is included in this manual. Be sure to follow the instructions.

Please make sure that the end user receives this instruction manual.

This instruction manual is prepared for an electrical expert.

Symbols have the following meaning.

Incorrect handling of the

product will result in a haz-

ardous situation, such as

death or serious injury.

Incorrect handling of the

product may result in a

hazardous situation ac-

cording to circumstances.

The electrical work shall be performed by qualified personnel (electrical expert).

Inspection and maintenance should be performed by qualified personnel (electrical expert). Before performing wir-

ing works, turn off the upstream circuit breaker. Failure to do so may expose you to electrical shock.

Tighten the terminal screw with the torque specified in the instruction manual. Failure to do so may cause a fire.

Do not install or store in an abnormal environment with high temperature, high humidity, dust, corrosive gas, vibra-

tions, or shocks, etc. To do so may cause a fire, malfunction of the circuit breaker or make it inoperative.

Protect the circuit breaker so that foreign particles, such as dust, concrete powder and iron powder, and rain water

will not enter the circuit breaker. Failure to do so may cause malfunction or fire.

When the circuit breaker trips automatically, remove the cause before turning on the handle. Failure to do so may

cause an electric shock or a fire.

Retighten the terminals periodically. Failure to do so may cause a fire.

Use the product in 50/60 Hz. Failure to do so may cause malfunction, inoperativeness or fire.

Do not use in strong magnetic field.

When using a transceiver, keep it off at least 1 meter from the ACB.

Do not disassemble.

Malfunction and operation fallures can be caused.

Dispose of the product as industrial waste.