2 | Worm Gearbox line

1General Considerations ..............................................................................Erro! Indicador não definido.

1.1Safety and information indications ...........................................................Erro! Indicador não definido.

1.2General information.............................................................................Erro! Indicador não definido.

1.3Exclusion of liability .............................................................................Erro! Indicador não definido.

1.4Copyright and Protection Rights..........................................................Erro! Indicador não definido.

2General safety ..............................................................................................Erro! Indicador não definido.

3Transport ................................................................................................................................................. 7

3.1Moviment.............................................................................................Erro! Indicador não definido.

4Storage..........................................................................................................Erro! Indicador não definido.

4.1Period without operation......................................................................Erro! Indicador não definido.

4.2Long Term Storage .............................................................................Erro! Indicador não definido.

4.3Storage Preparation ............................................................................Erro! Indicador não definido.

4.4Operation after Storage.......................................................................Erro! Indicador não definido.

5Installation ............................................................................................................................................. 10

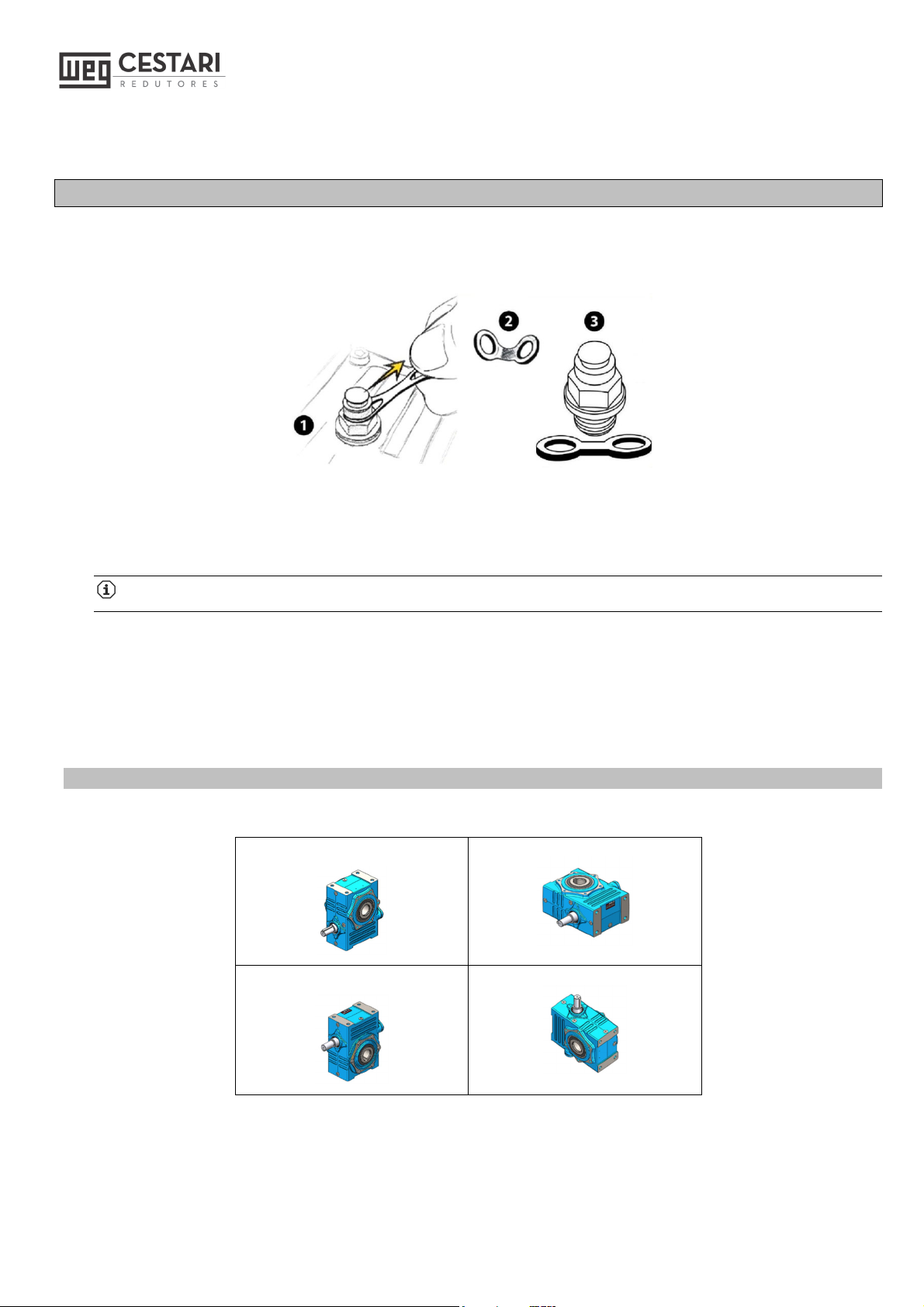

5.1Example of Working Position ..............................................................Erro! Indicador não definido.

5.2Minimum permissible diameter for the drive element mounted on the shaftErro! Indicador não

definido.

5.3Mounting position of notched hub .......................................................Erro! Indicador não definido.

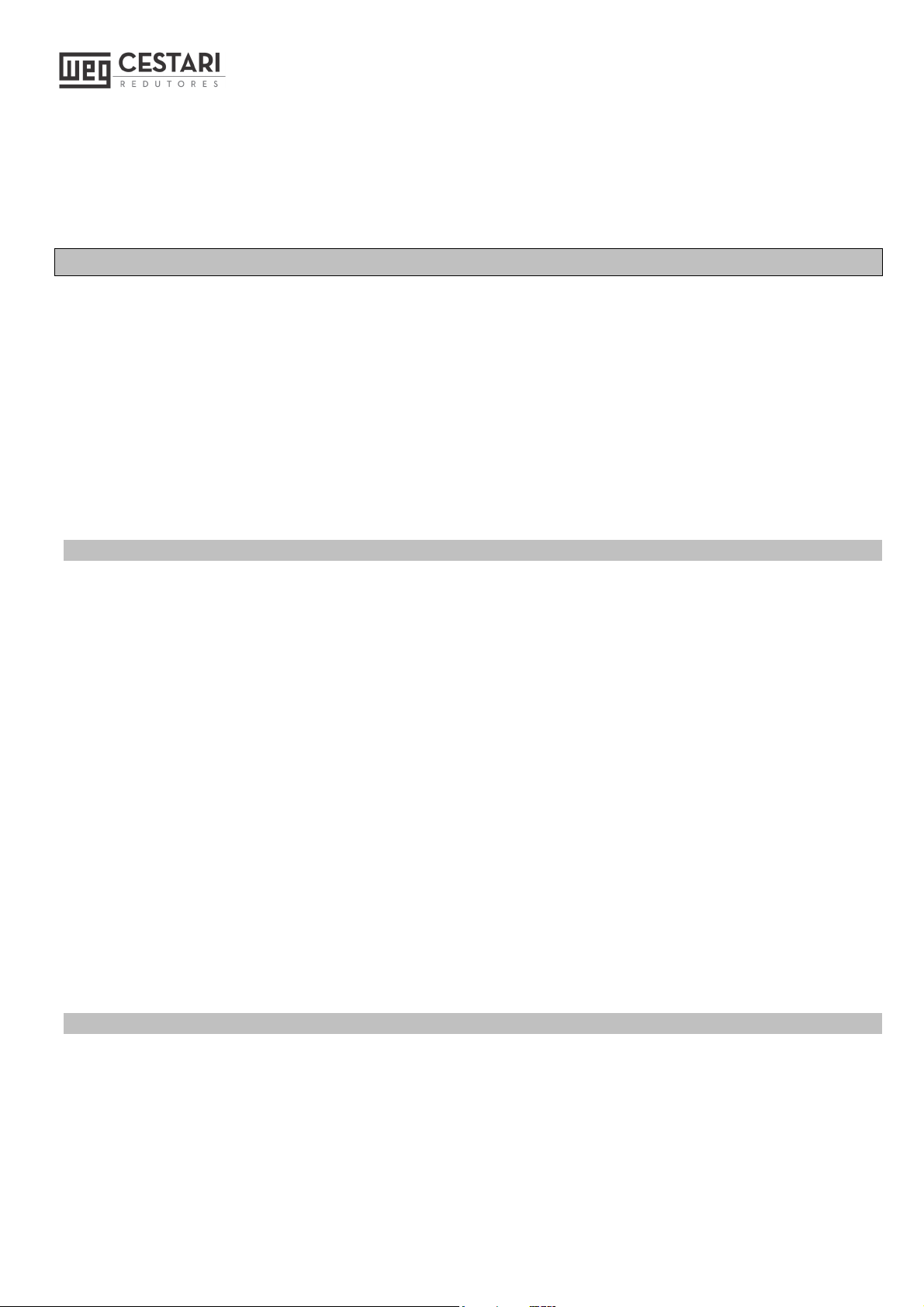

5.4Axial clearance for bearing mounting ............................................................................................... 13

6Lubrication ...................................................................................................Erro! Indicador não definido.

6.1Operating temperature and oil temperature ........................................Erro! Indicador não definido.

6.2Quantity of lubricant Magma M Line................................................................................................. 16

6.3Lubricant quantity Alumag line ......................................................................................................... 16

6.4Quantity of lubricant Magma K Line ................................................................................................. 16

6.5Quantity of lubricant 1st stage of the duplex gearboxes Magma K line .......................................... 17

6.6Recommended synthetic lubricants ................................................................................................. 17

6.7Recommended mineral lubricants.................................................................................................... 17

6.8Check list - Installation and assembly of gearboxes ........................................................................ 18

7Operation ......................................................................................................Erro! Indicador não definido.

8Maintenance .................................................................................................Erro! Indicador não definido.

8.1Maintenance Task List ........................................................................Erro! Indicador não definido.

8.2Gearbox faults .....................................................................................Erro! Indicador não definido.

9Repairs..........................................................................................................Erro! Indicador não definido.

9.1Compact Single Input Assembly ...................................................................................................... 23

9.2Compact single entry list .................................................................................................................. 24

9.3Compact Dual Input Assembly ......................................................................................................... 25

9.4Compact dual entry list...................................................................................................................... 26

9.5Single input Assembly ...................................................................................................................... 27

9.6Simple Input List............................................................................................................................... 28

9.7Dual Input Assembly ........................................................................................................................ 29