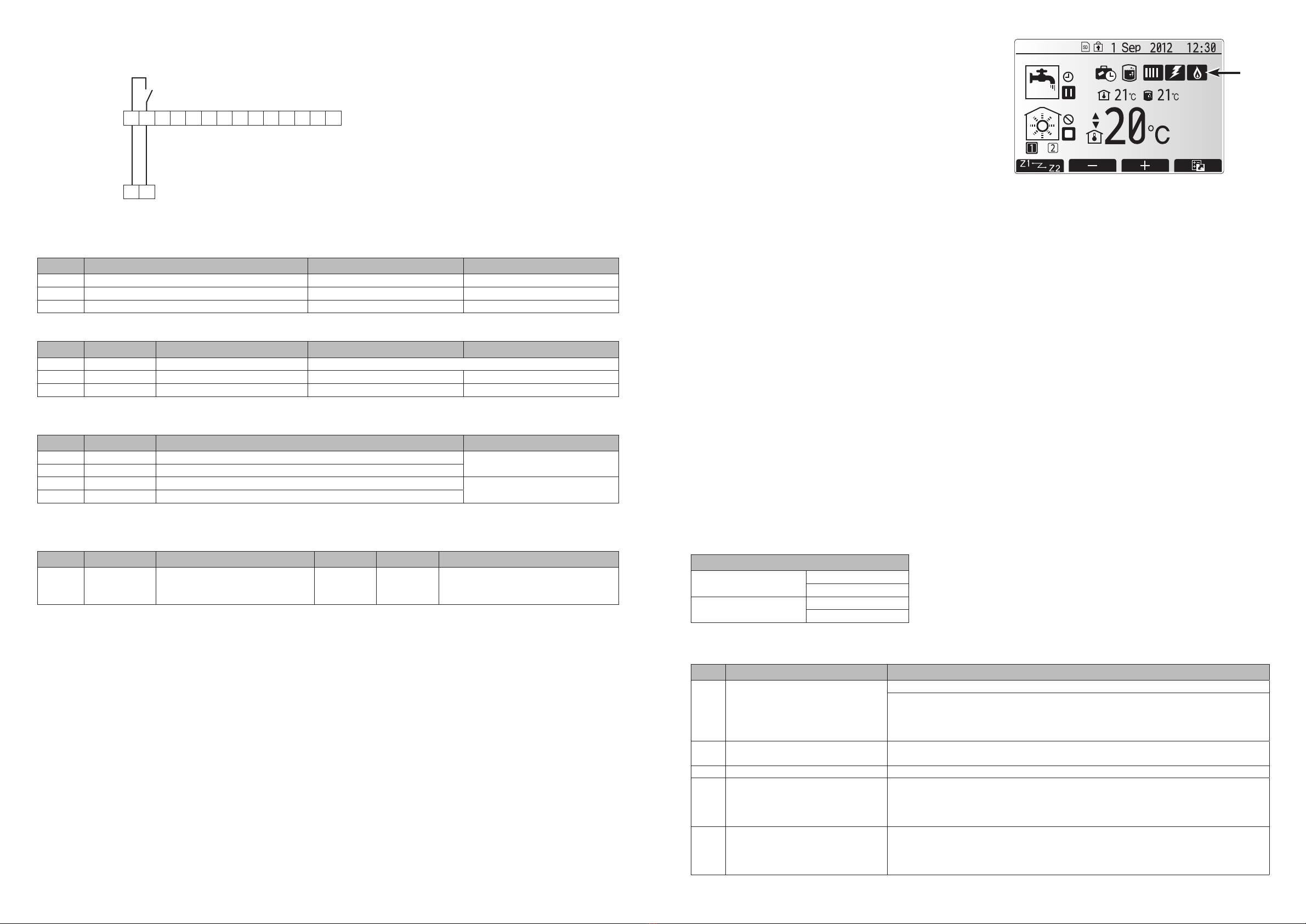

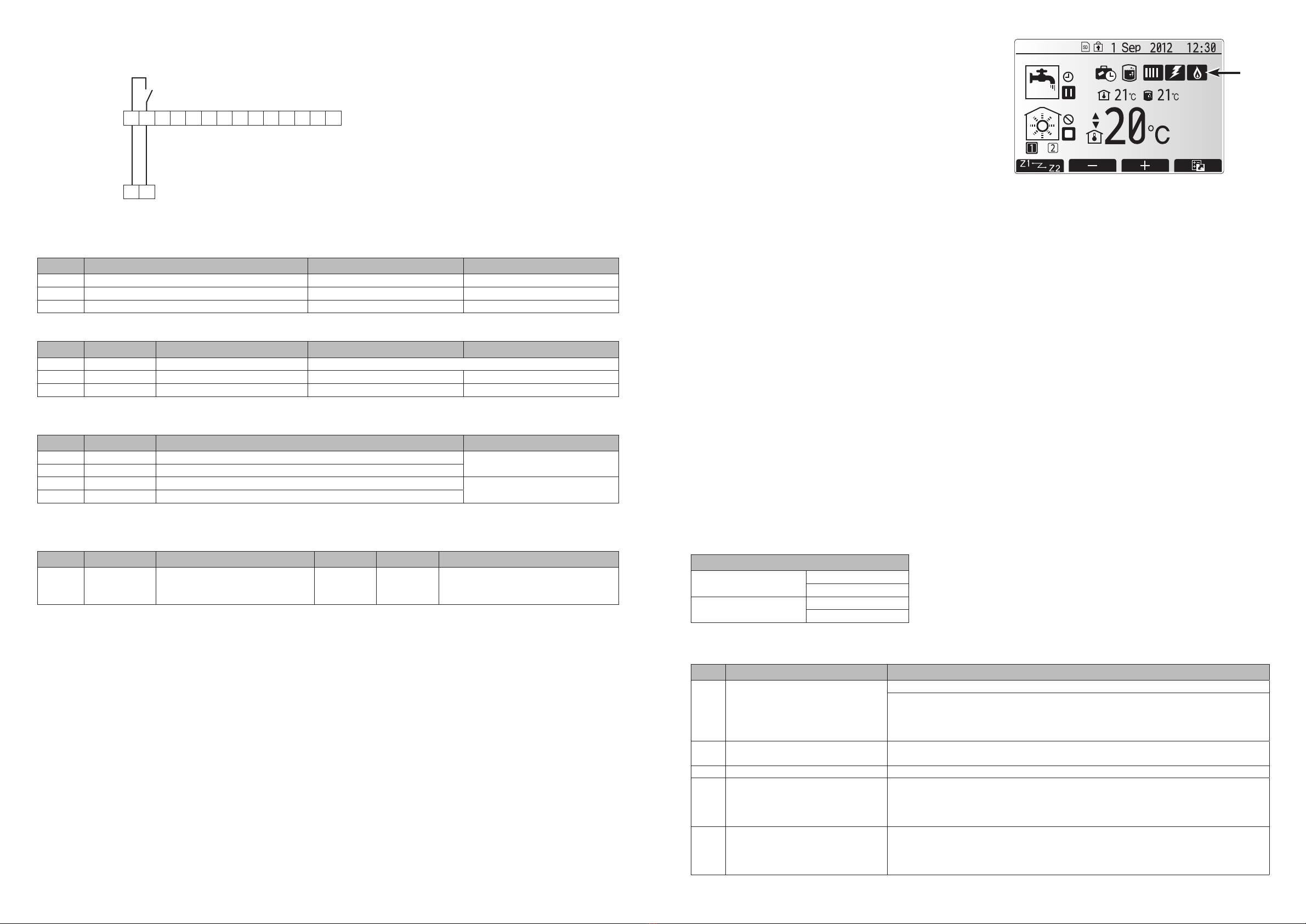

Screw positions

6

Place the terminal

blocks so that the

orientations of the

labels are correct.

BH79T377H02

2. Setting the Main Controller

<Main screen icons>

When boiler is running, icon 1 is displayed.

<Service menu>

(1) Heat source setting

Select heat sources to run.

[Standard] *1

• Heat pump and Electric heater

[Heater] *1

• Electric heater only

[Boiler]

• Boiler only (for emergency operation)

Note: DHW mode is NOT available in this setting.

[Hybrid]*1

• Standard (Heat pump and Electric heater) and Boiler

• Switch between heat sources dependent on energy saving calculation (running cost/CO2 emission) or outdoor ambient tempera-

ture. *2

*1 FTC4 can switch heat source to Boiler by external signal when Boiler is selected in “External input settings”.

*2 Make detailed settings in "Boiler settings" of "Operation settings ".

(2) Operation settings → Boiler settings

• Select prioritised items in energy saving calculation.

[Hybrid settings]

(a) Outdoor ambient temperature

Set the ambient temperature to switch to Boiler operation.

(b) Priority mode

Ambient: Heat source is switched based on outdoor ambient temperature.

Cost: Heat source is switched based on running cost or outdoor ambient temperature.

CO2: Heat source is switched based on CO2 emission or outdoor ambient temperature.

[Intelligent settings]

Set parameters for energy saving calculation.

The following settings will be applied when "Cost" or "CO2" is selected in Priority mode.

(c) Energy price

Enter unit prices of electricity, and gas or oil (depending on boiler type) per 1 kWh.

(d) CO2emission

Enter CO2 emission amount from electricity or boiler (gas or oil).

(e) Heat source

Enter outdoor unit capacity, electric heater capacity, and boiler efciency.

(3) External input settings

• Select which heat source to run when IN4 or IN5 external input signal is received.

• If Boiler is selected, boiler will start running by receiving external input signals.

External input settings

Demand control (IN4) Boiler

Heat source OFF

Outdoor thermostat (IN5) Boiler

Heater

3. Error codes

Code Error Action

LC Boiler circulation water temperature

overheat protection

Check if the setting temperature of the Boiler for heating exceeds the restriction.

Flow rate of the heating circuit from the boiler may be reduced. Check for

water leakage

strainer blockage

water circulation pump function

•

•

•

LD Boiler temperature thermistor

(THWB1, THWB2) failure

Re-attach any thermistors that have become dislodged. Check resistance across the

thermistor.

LE Boiler operation error Re-attach any thermistors that have become dislodged. Check the status of the boiler.

LH Boiler circulation water freeze

protection

Flow rate of the heating circuit from the boiler may be reduced. Check for

water leakage

strainer blockage

water circulation pump function

•

•

•

LL Setting errors of Dip switches on

FTC4 control board

For boiler operation, check that Dip SW1-1 is set to ON (With Boiler) and Dip SW2-6

is set to ON (With Mixing Tank).

For 2-zone temperature control, check Dip SW2-7 is set to ON (2-zone) and Dip

SW2-6 is set to ON (With Mixing Tank).

1.3 Wiring for boiler control

Connect OUT10 to boiler external input (room thermostat).

1.4 Dip switch functions

Set Dip SW1-1 and SW2-6 to ON .

Dip switch

Function OFF ON

SW1-1 Boiler WITHOUT Boiler WITH Boiler

SW2-5 Automatic switch to backup heater only operation Inactive Active

SW2-6 Mixing tank WITHOUT Mixing tank WITH Mixing tank

<Signal inputs>

When connecting room thermostat (eld supply), wire the cable to IN1.

Name

Terminal block

Item OFF (Open) ON (Short)

IN1 TBI.1 1-2 Room thermostat 1 input Refer to SW2-1.

IN4 TBI.1 7-8 Demand control input Normal Heat source OFF/Boiler operation

IN5 TBI.1 9-10 Outdoor thermostat input Standard operation Heat operation/Boiler operation

<Thermistor inputs>

For details on where to install the thermistors, refer to chapter “1.2 Pipe work” in this manual.

Name

Terminal block

Item Optional part model

THW6 TBI.2 7-8 Zone 1 ow water temp. thermistor (Option) PAC-TH011-E

THW7 TBI.2 9-10 Zone 1 return water temp. thermistor (Option)

THWB1 TBI.2 3-4 Boiler ow water temp. thermistor —

THWB2 TBI.2 5-6 Boiler return water temp. thermistor

<Outputs>

Connect OUT10 to boiler external input (Room thermostat).

Name

Terminal block

Item OFF ON Signal/Max current

OUT10 TBO.1 1-2 Boiler output OFF ON

non-voltage contact

• 220 - 240V AC (30V DC) 0.5 A or less

• 10 mA 5V DC or more

Note:

• OUT10 is separated by basic insulation from other external output signals in FTC4.

• Connect the surge absorber according to the load at site.

• When the wires are wired to adjacent terminals , use ring terminals and insulate the wires.

• Do not splice the wiring to extend or shorten it, or this could affect correct monitoring of each temperature.

If the wiring is too long, bundle it with a strap to adjust the length.

(External input)

Room thermostat

1

1 2 3 4 567 8 9 10 11 12 13 14

FTC4 (OUT10)

TBO.1 1-2

Boiler

Non-voltage contact

• 220 - 240V AC (30V DC) 0.5 A or less

• 10 mA 5V DC or more