Form 801817 Page Number - 3

Introduction

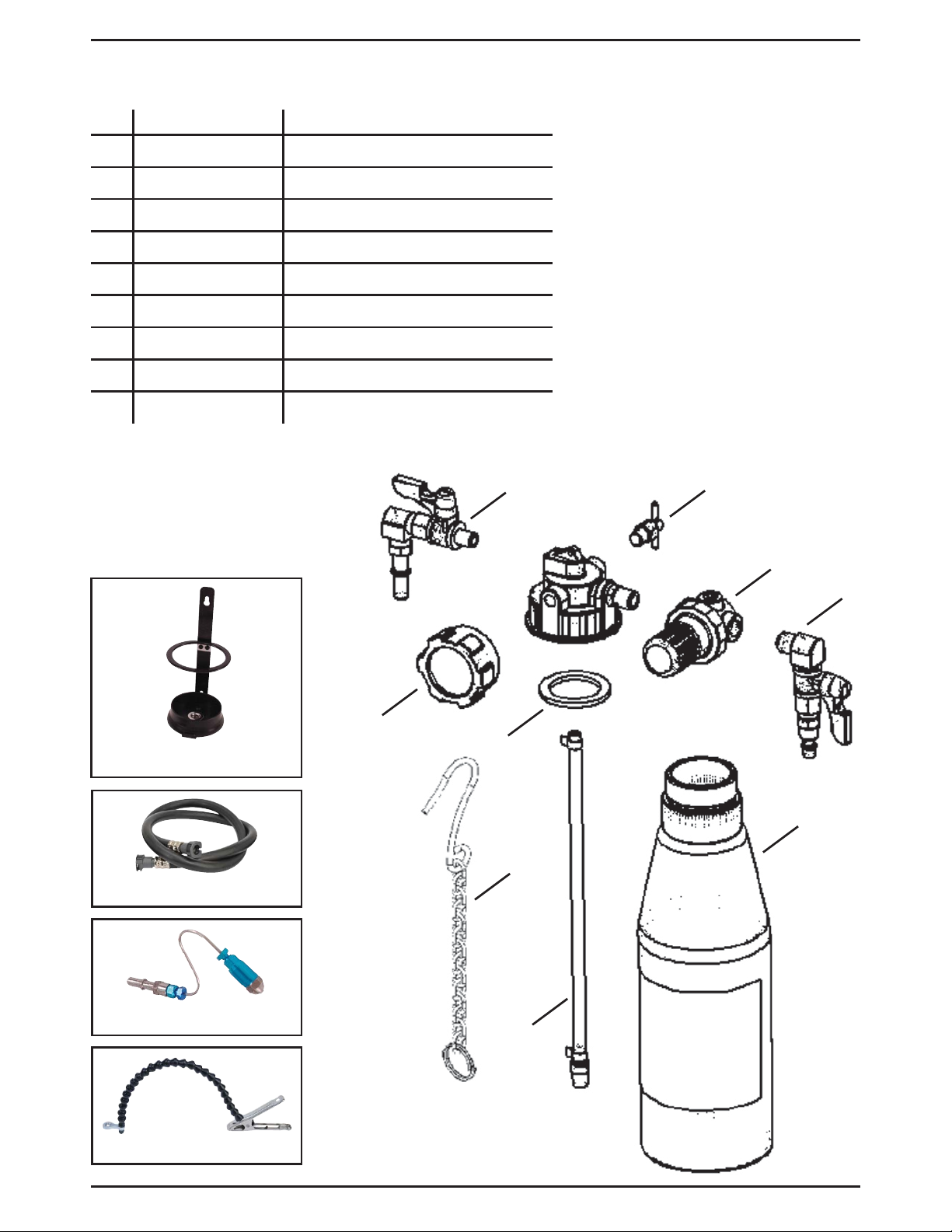

The Mityvac Fuel Injection Cleaner can perform

two types of engine cleaning services:

1. Fuel Injector Cleaning

2. Air Induction System Cleaning

Fuel Injector Cleaning is performed by installing

the Cleaner directly into the fuel delivery system,

where it dispenses a specially formulated solution

directly into the engine. The solution dissolves

deposits from the injectors and prevents future

buildup.

Air Induction System Cleaning is performed by

inserting a nozzle (sold separately) into the air

intake stream. The Cleaner delivers cleaning

solution to the nozzle under pressure, where it

is injected into the air stream as a fine mist. The

solution coats the inside of the throttle body,

intake manifold, and valves, to loosen and

dissolve carbon deposits. The deposits are then

burned off by engine combustion.

Both types of cleaning services can enhance

engine performance, improve fuel economy,

reduce maintenance and improve emissions.

Application Precautions

This equipment is intended for use by vehicle

service professionals with experience and knowl-

edge of its application and limitations. While it is

designed for servicing a variety of vehicles in a

safe and convenient manner, due to variations

between vehicle manufacturers, makes, models

and years, use of this equipment is not always

feasible, possible, or recommended.

Use common sense when operating this equip-

ment. If something does not seem or feel right,

stop immediately and consult a professional with

knowledge of the application. Don’t force the use

of this equipment on an application for which it is

not intended.

The procedures documented in this manual

are to serve as guidelines for general use of

this equipment. In addition to these guidelines,

always follow the vehicle manufacturer’s recom-

mended procedures when attempting to use this

equipment.

When installing this equipment for induction

system cleaning, insure the cleaning solution is

introduced downstream from the mass airflow

sensor. Installing the nozzle upstream of the sen-

sor can cause permanent damage to the sensor.

Harsh cleaning solutions can damage some

delicate idle air control valves. If unsure of the

effect of the cleaning solution on the IAC for the

vehicle, consult the vehicle’s manufacturer for

further information.

When performing a fuel injector cleaning service,

keep the Cleaner pressure below the rated fuel

pressure of the vehicle to prevent damage to the

injectors, and to prevent cleaning solution from

bypassing the regulator and entering the fuel

tank.

Safety Precautions

• Carefully read and understand these

instructions prior to using this equipment

• Always wear safety glasses when using this

equipment

• Avoid burns by remaining cautious of engine

parts that may become hot when the engine

is running

• Operate the vehicle only in a well ventilated

area, and away from potential sources of

flame or ignition

• Prior to starting an engine, make sure all

components of the tester, body parts, and

personal clothing are clear of rotating engine

components.

• Never leave a vehicle unattended during the

cleaning process.

• Check and secure all fuel system connec-

tions before starting the vehicle or pressur-

izing the system.

• Always keep a fire extinguisher on hand

when performing fuel related procedures.

Make sure the extinguisher is rated for fuel,

electrical, and chemical fires.

• Protect painted surfaces from fuel and

cleaning solutions.

• Release fuel system pressure before

servicing or disconnecting any fuel system

related components.

• This system is designed for use on gasoline

systems only.

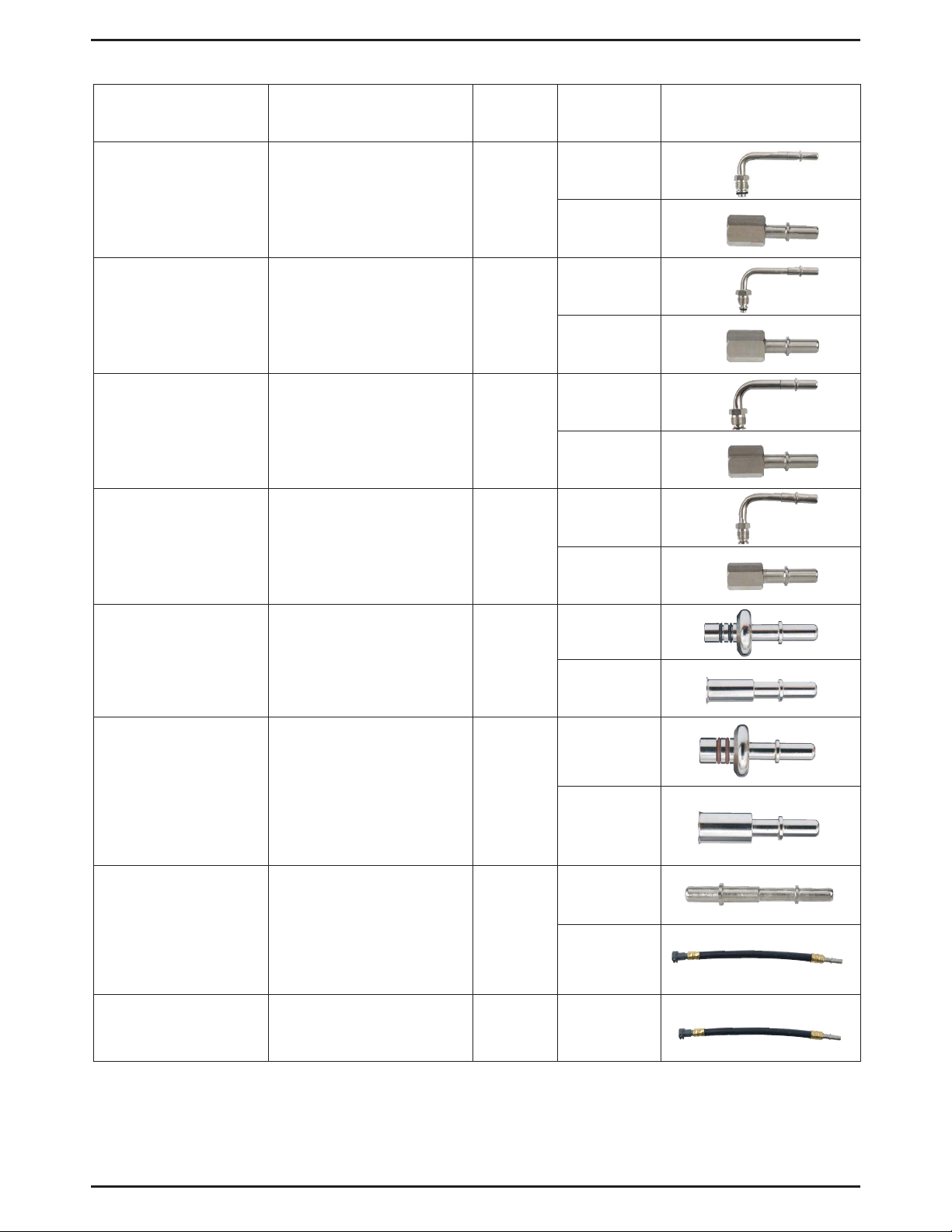

MVA550 - Decarb Nozzle MVA551 – Extended Nozzle Clamp