Directory of contents

3Installation instructions

1Introduction......................................................................... 5

1.1About this manual ............................................................................ 5

1.1.1Explanation of signs .................................................................................. 6

1.2Staff qualification ............................................................................. 7

1.3Use of the unit................................................................................... 7

1.4Warranty............................................................................................ 7

2Safety information.............................................................. 8

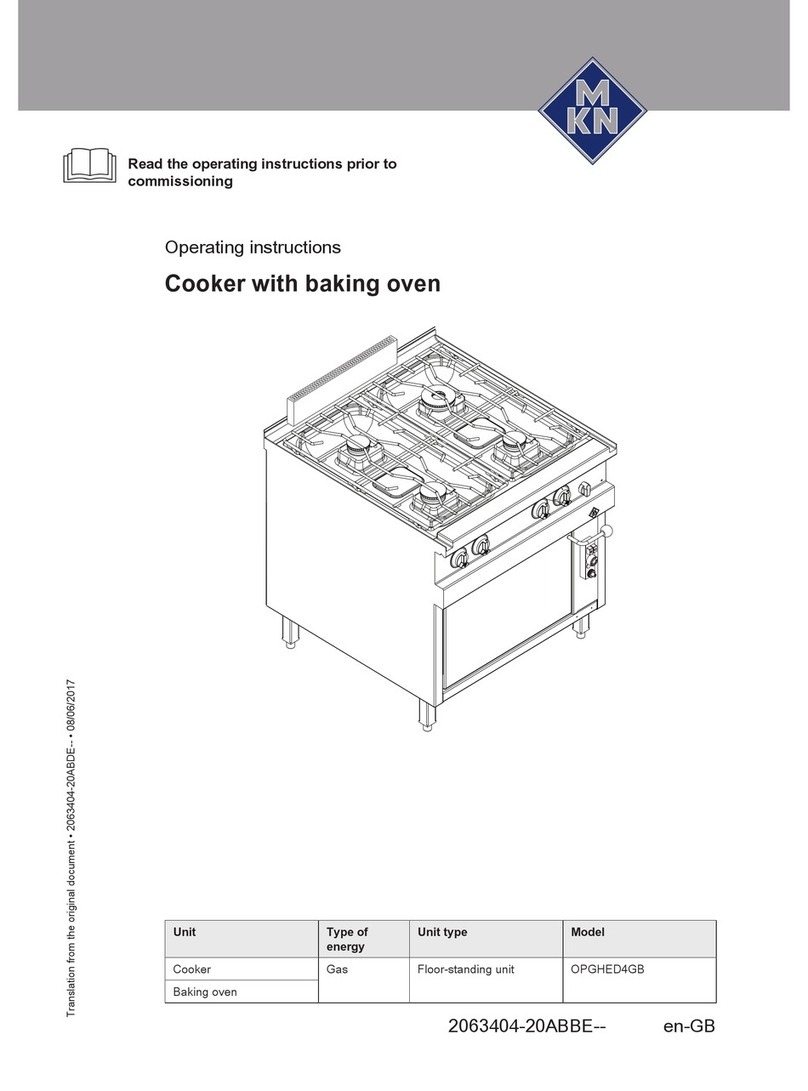

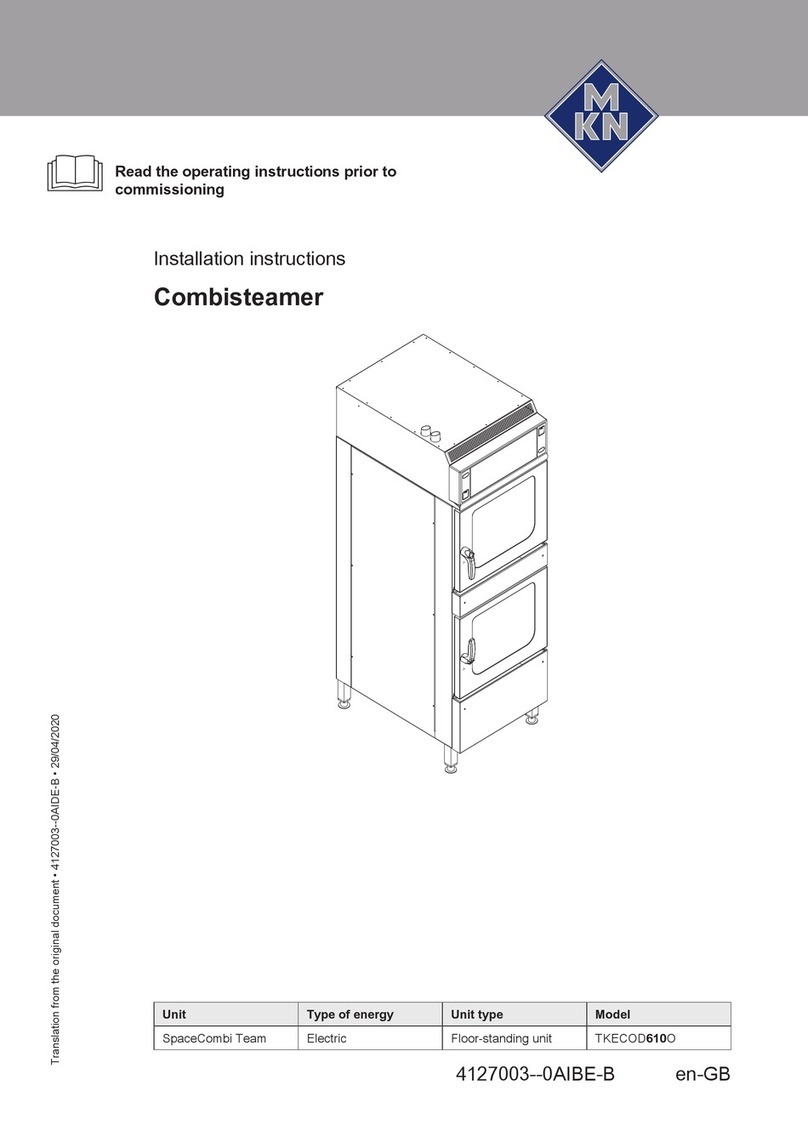

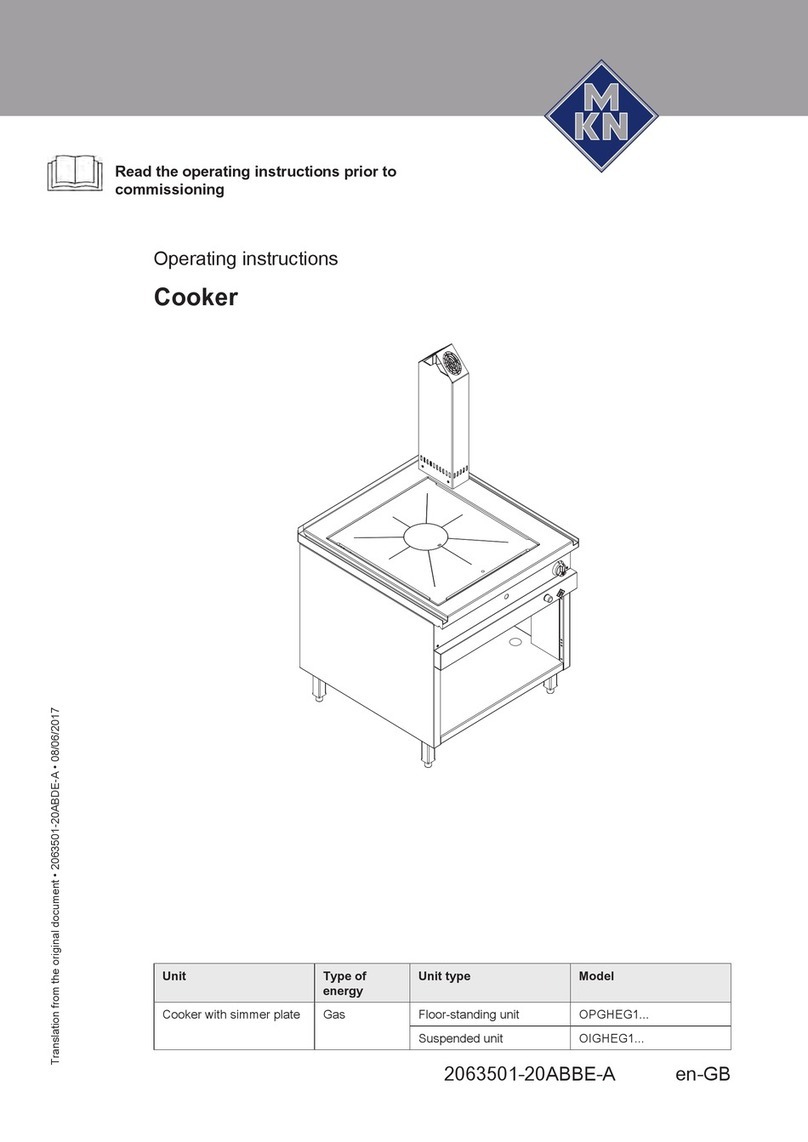

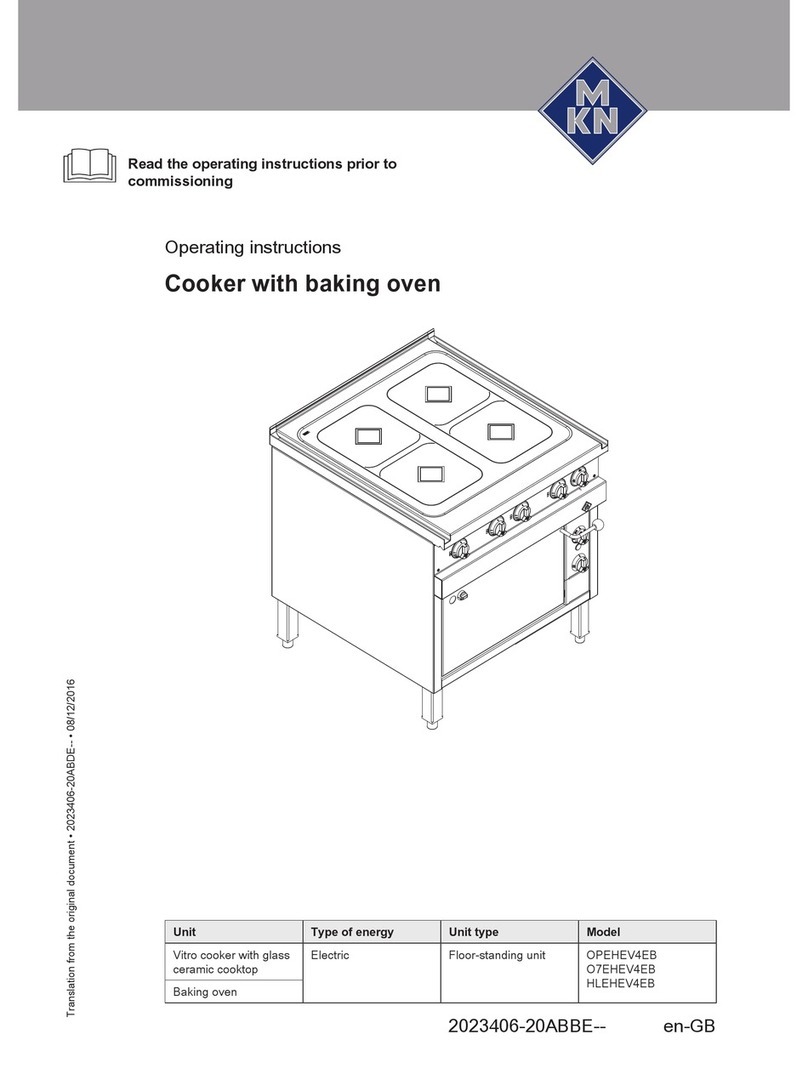

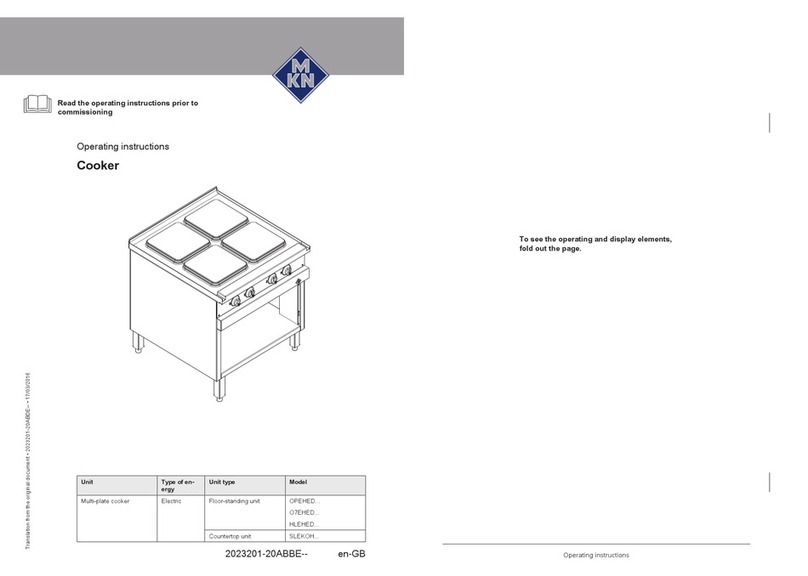

3Description of the unit ..................................................... 10

3.1Overview of the unit ....................................................................... 10

3.2Equipment and connection data................................................... 11

4Transporting the unit ....................................................... 16

4.1Transporting the unit to the installation site ............................... 16

4.2Unpacking the unit ......................................................................... 17

5Setting up the unit............................................................ 18

5.1Minimum clearances ...................................................................... 19

5.2Lifting the unit off the pallet .......................................................... 19

5.3Placing the unit on the equipment legs........................................ 20

5.4Aligning the unit ............................................................................. 20

5.5Checking the filter on the air recirculation hood......................... 21

5.6Fastening the unit to the floor....................................................... 22

5.6.1Securing the unit against tilting ............................................................... 22

6Connecting the unit.......................................................... 25

6.1Opening and closing the housing................................................. 25

6.1.1Removing and attaching the rear panel .................................................. 25

6.2Making the electrical connection.................................................. 26

6.2.1Connecting the power connection cable ................................................. 28

6.2.2Connecting the power optimizing system................................................ 29

6.2.3Connecting to the potential equalisation circuit ....................................... 30

6.3Connecting the kitchen management system ............................. 31

6.4Making the basic control setting................................................... 32

6.4.1Changing the basic control setting .......................................................... 32

6.5Making the water connection ........................................................ 33

6.5.1Connecting the tap water connection line ............................................... 34

6.5.2Connecting softened tap water to both connections ............................... 35

6.6Making the wastewater connection .............................................. 35

6.6.1Connecting the wastewater line to a permanent connection................... 36

6.6.2Connecting wastewater line to collection basin (optional)....................... 37

7Checking operation.......................................................... 38

7.1Checking the air recirculation hood ............................................. 38

4127002--0AIBE-C