With VC and EC types the air exhaust is

protected by a cover at the rear wall of the

unit. This cover is placed inside the unit

while shipping. When installing the unit,

insert the cover into the horizontal openings

bellow and above the exhaust to attach it

behind the exhaust.

DC-type – regarding the fact that it is the

inner chamber only which is resistant to

corrosive effects, the following must be

ensured during the application:

a) Processes specied in the previous

chapter must be performed in the chamber

in closed vessels (corrosive substances

release into the chamber must be prevented);

b) Exhalations from the exhaust outlet must

be exhausted actively to prevent vapour

condensation on the outlet and its dripping

down to the electric part of the device;

c) The whole device must be placed in a

no-corrosive atmosphere (damage of the

source and regulation electronics must be

prevented).

The units are designed for indoor operation

within the ambient temperatures ranges

from 5 °C to 40 °C and at maximum relative

humidity 80 %.

The oven shall be installed in a distance of

min. 100 mm from the rear and sidewalls.

The temperature of the outlet air on the

exhaust may be up to 250 °C (or 300 °C);

this area is labeled by .The walls near

the oven shall be incombustible.

The load-bearing capacity of the oor

during installation of the device shall

correspond to the weight of the unit itself

taking the weight of the maximum charge

into consideration (see chapter

5 - Parameters of the Unit).

The unit must not be placed on a support

that could cause a danger of re or

smothering in case of falling some hot

object out of the unit.

Noinammable,explosiveortoxic

materialsmaybeputintooven!The

same applies to materials that could

release such substances.

Material is only to be put on trays, never

directly on the bottom of the unit!

No articles may be put on he external

surface of the unit.

The unit is not intended for warming up the

liquids.

The units are not intended for use in the

atmosphere with a possible danger of

ammable or explosive anesthetics.

Any assembly or disassembly may be

done only when disconnected from the

mains! After switching the unit off with

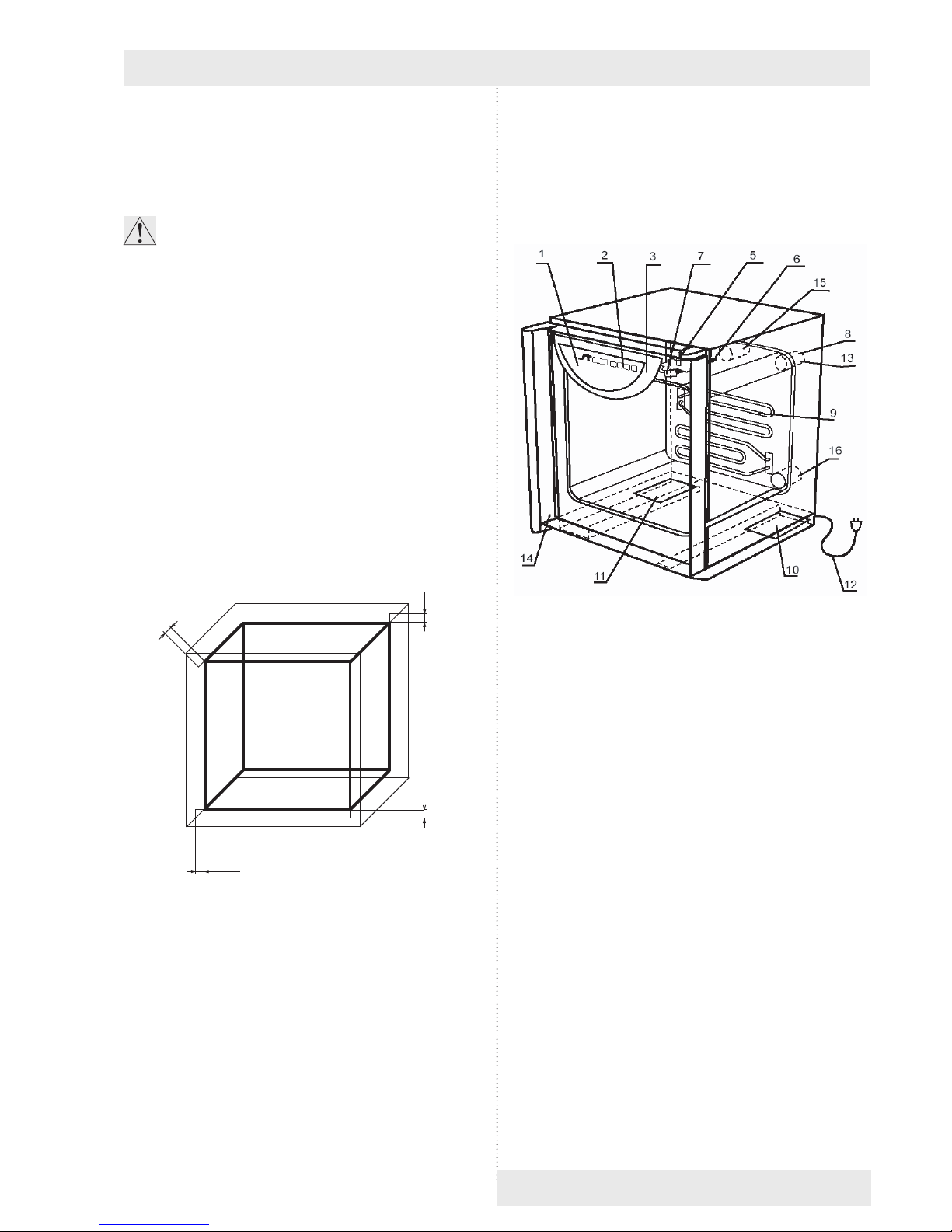

thekey(key11,g.4)theunitcomes

onlytoastand-bymode,however,itis

not disconnected from the mains!

● If the unit is not used for a longer time,

disconnect it from mains by pulling the

power cord out of the socket.

The units are supplied with the maximum

permitted temperature set to the maximum.

The power cord must not come in contact

with hot parts of the units – with the

exhaust hole cover.

● Protection of the temperature box, its

surroundings and processed material

against inadmissible temperature excess is

secured by a safety system.

Pull out and subsequently push in the

upper metal plate piece of internal chamber

carefully, there is a danger of cutting

through the rubber gasket of the chamber

through careless manipulation.

The maximum permitted loads: see chapter

5 - Parameters of the Unit.

When operating the cabinets at high

chamber temperatures there can be the

maximum allowed temperature of 70 °C at

their external surface (exhaust ports and

their surroundings and the surroundings

of the chamber sealing, window and door

surface in case of the optional type with

window in door) surpassed and there is a

danger of burns. Please be very careful.

● During the operation of the devices of

404 and 707 at high temperatures a

deformation of the inner door surface

occurs as a consequence of thermal

tension, which makes their closing more

Instructions for use

4 LSI-S_np_en_1309_mmm_V2.10_B2V