7

mo systeme GmbH & Co.KG

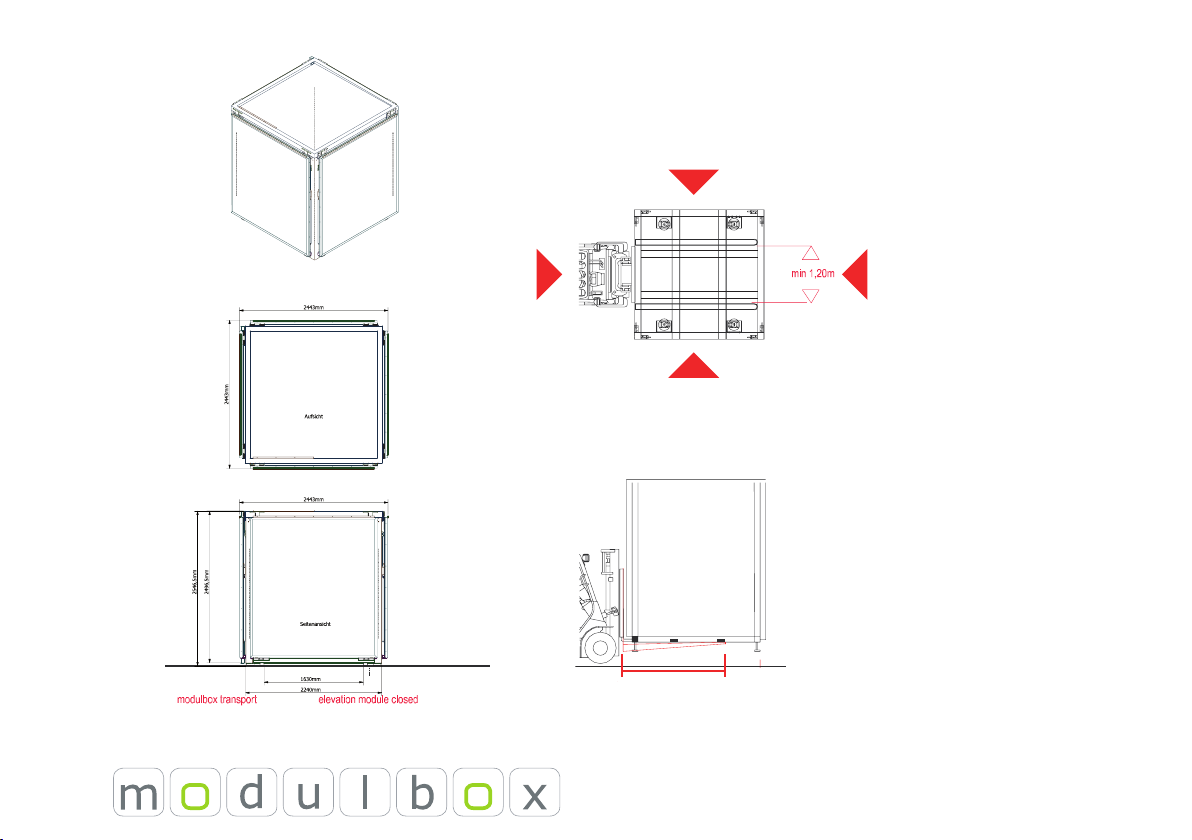

C. Transport and Installation

The modulbox has to be set up horizontally so

that any rain water can be channelled away at the

lowest point. Do not open the modulbox during a

storm. Further usage instructions are to be found

in the section ‘Warnings’ and the introduction to

use.

C.1 Transport with truck and fork-lift

The modulbox has a total height of 2.65m and a

weight of up to 2t per modulbox, depending on

ttings. These data should determine the choice of

transport vehicle and fork-lift (load centre).

The transport vehicle has to have a suitable load

height (Jumbo Roller).

During transport on an open vehicle the

modulbox should be covered with a transport

cover (special ttings).

When using a protective cover during transport,

protect the corner of the rain tube in order to

ensure that the cover is not ripped.

Fork-lift trucks whose forks are a minimum of

1,80m long can lift the modulbox HC2 from all

4 sides (the two sides marked with the sticker).

(C1.3). In this case it is important to place the

modulbox on the transport vehicle in such a way

that it can be unloaded from the same side – see

Figure.

The modulbox must not be stored on its

adjustable feet (C1.1) during transport and

storage. These should be screwed in. Suitable

timber bearers are to be placed under the

modulbox (c. 10x10x80cm) (C1.2).

When on the transport vehicle, the modulbox

must be tightly secured so as to prevent any

movement. Securing straps should be fastened to

the fastening points. Four securing straps must be

used for each modulbox (one at each corner).

Alternatively, securing straps can be attached from

the oor points on the truck over the attic sheeting

of the modulbox. If so, careful attention must be

paid that the securing straps do not damage the

foldable roof parts.

Check every installation site for the modulbox

very carefully. Make certain that the ground is rm

enough to bear the modulbox. On soft ground

the modulbox must be placed on load-distributing

stone slabs or steel plates. Bear in mind that,

depending upon use, a load of up to one ton must

be borne by each of the feet.

External measurements of the modulbox

Length x width x height

2.45m x 2.45 x 2.65

Weight: up to 2t gross weight