TDR Eco Pro User manual

©Total Disc R epair Ltd | www. totaldiscr epair.co.uk | Technical Support: 0800 412 5424 - support@ totaldiscr epair.co.uk | Sales: 01202 489 500 - sales@ totaldiscr epair.co.uk

What’s In This User Guide?

Getting started - repair a disc right now

Getting to know your machine and how it works

Advanced features of your machine

Maintenance and other useful information

©Total Disc R epair Ltd | www. totaldiscr epair.co.uk | Technical Support: 0800 412 5424 - support@ totaldiscr epair.co.uk | Sales: 01202 489 500 - sales@ totaldiscr epair.co.uk

Getting Started

Initial setup

Basic operation

Inspecting a repaired disc

With the machine you will nd a setup sheet which

includes a list of contents and briey explains the

setup of the machine. Once the machine is ready to

go, the display will show “CD/DVD” and will display

the number of minutes remaining on the chip.

Choose a disc for repair. For information on what

can and cannot be repaired please refer to the

“Disc Types” sheet.

For this rst disc, we

will run a light, 30

second repair cycle.

Choose a CD, DVD,

game or data disc (not

a PS3/Blu-ray at this

stage - we will discuss

these later).

The disc should come out of the machine clean, dry

and warm. Have a look at the repaired side; the light

repair should have made a visible improvement.

If a more heavily damaged disc was chosen, the disc

may need an additional repair.

Repair process:

1. The lid will automatically open when you turn the

power on.

2. Place the disc shiny side up on the turntable.

3. Close the lid rmly until it clicks.

4. The machine will automatically start a 30 second

cycle.

5. Once the cycle has nished, the lid will open.

6. Remove the repaired disc.

Polishing pads

Power switch

Chip slot

Display Start

button

Stop

button

Polish bottle

Feed tubes

Bottle Holder

Water bottle

Power Inlet

Turntable

WARNING - Closing the lid without a disc may

cause damage to the pads and turntable. Always

place a disc on the turntable if closing the lid

when the machine is switched on.

Parts of the machine

Function

button

Disc Well

Polishing

pads

Compound

nozzle valve

Water drip

feed

Compound

nozzle valve

Water drip

feed

Filter

©Total Disc R epair Ltd | www. totaldiscr epair.co.uk | Technical Support: 0800 412 5424 - support@ totaldiscr epair.co.uk | Sales: 01202 489 500 - sales@ totaldiscr epair.co.uk

Getting To Know The Machine

Understanding the repair cycle

Cleaning the pads

Setting up the consumables

The Eco Pro uses a single-stage disc repair process.

In other words, the machine applies a constant,

gradual repair to the disc in one operation.

A combination of abrasive liquid and heat is used to

perform a repair. The plastic playing surface is heated

up and softened, and then the liquid abrasive grinds

away a thin layer of plastic, removing the scratches

within it.

The machine uses two soft foam pads to apply both

the liquid abrasive and water solution to the disc. The

liquid abrasive removes the scratches while the water

solution is used to stop the disc overheating.

With this process, the longer the disc is being

repaired the more scratches are removed.

For a clean and dry disc every time it is important

to clean the pads regularly. There is a reminder

programed into the machine which displays every 20

repair cycles. The message is “Clean Pads”.

Press any button to clear the message.

Simply rinse the pads with water from a tap until all

visible signs of polish residue are removed. We advise

waiting until the pads have dried out before re-tting

them in the machine.

If you choose not to clean the pads at this stage you

will start to see some residue transfer to the disc.

This may not directly aect the repair, but will require

you to wipe each disc after each repair.

Everything you need to operate your machine is

included within the consumables pack. Each pack is

designed to last for a set time – 800 minutes.

There will be a little surplus polish in the container

when the chip expires. This is normal. The bottle is

overlled a little to ensure you do not run out. There

is no reason to keep this surplus as the new bottle is

also a little overlled - please discard it with the used

pads and the chip.

The pads are attached with Velcro and are very

simple to change.

1. Peel the pads away from the edge of the pad

holder.

2. Position the new pads to line up with the pad

holder and rmly stick them down.

Replacing the pads

When the consumables have expired the message

“Change KEY CARD” (Change Consumables) will

appear. Discard the used pads, polish, water and chip

before installing new ones.

Unlike most disc repair machines, the Eco Pro does

not create any signicant waste, however because

of the heat generated by the machine, any leftover

compound dries and so a small powdery residue will

build up over time.

The well inside the machine is designed to catch most

of this residue (please refer to the Maintenance section

on how to clear this).

There are two other parts of the machine which collect

reside and will ultimately eect the repair over time.

Always remember these important points,

Please read the next sections on how to combat this

and how to get the most from your machine.

Compound considerations

Clearing the nozzle valves

The two nozzle valves are designed to stop the

compound drying in the lines. However these will over

time become blocked with dried compound.

Before using the machine, remove the nozzle valves,

roll them between your ngers to clear any dried

polish and then reinstall them on the machine.

Blocked nozzle valves will damage your machine

Dirtypadswillgiveapoornish

Nozzle valves

©Total Disc R epair Ltd | www. totaldiscr epair.co.uk | Technical Support: 0800 412 5424 - support@ totaldiscr epair.co.uk | Sales: 01202 489 500 - sales@ totaldiscr epair.co.uk

Getting To Know The Machine

Installing the chip

Changing the polish & water

Priming the pumps

Clearing the polish tube

There is a chip attached to a card in each

consumables pack, which monitors consumables

usage and ensures the highest quality repairs.

The replacement polish is included in the consumables

pack. To change this:-

1. Unscrew the old bottle and replace with the new

one.

2. Ensure the marker on the polish tube is at the top

of the cap.

3. Rell the water bottle from the tap.

4. Ensure the water tube does not sit on the bottom

of the bottle.

Your machine will have already arrived with the polish

and water pumps primed and ready to go. However it

is important to understand how to do this yourself as

you will need to prime the pumps again if the tubes

become cleared of liquid for any reason.

If you are not going to use the machine for a while

it is important to clear the polish tube of polish so

that it doesn’t dry in the tube.

1. Press and hold “START” followed by “FUNC” to

start water pump. “Water Pump on” will show on

the display.

2. Once you see water coming out of the drip feed,

press any button to stop the pump.

Step 1 - Preparation

When priming pumps, place a tissue under the drip

feeds as shown to stop the turntable getting wet.

Step 2 - Priming the water

Step 3 - Priming the polish

1. Press and hold “STOP” followed by “FUNC” to

start polish pump. “Compound Pump on” will

show on the display.

2. Once you see polish coming out of the drip feed,

press any button to stop the pump.

1. Press and hold “START” and “STOP” together

followed by “FUNC” to start the polish pump in

reverse. “Compound Pump Rev” will show on

the display.

2. Once the tubes are empty press any button to

stop the pump.

Water

solution

Polish

* The slots are

dierent sizes

and cannot be

confused.

Marker

©Total Disc R epair Ltd | www. totaldiscr epair.co.uk | Technical Support: 0800 412 5424 - support@ totaldiscr epair.co.uk | Sales: 01202 489 500 - sales@ totaldiscr epair.co.uk

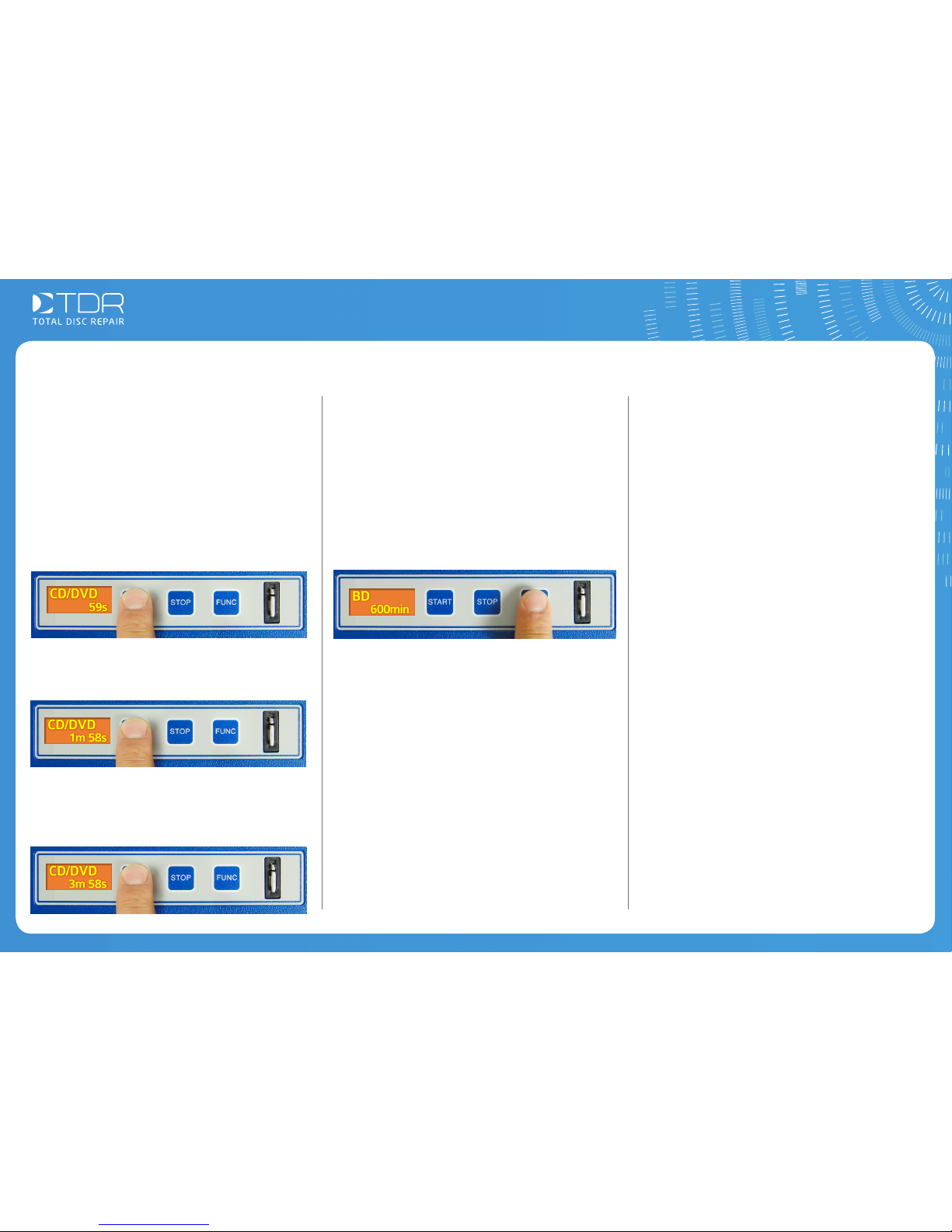

The Eco Pro is a single stage repair machine. The

depth of repair is dictated by the length of time that

the disc is processed for.

When you close the lid, the standard repair cycle will

start, which lasts for 30 seconds. However, you may

wish to extend this repair cycle for more heavily

damaged discs.

• Closing the lid starts a 30 second repair, pressing

the “START” button once during this repair will

extend the total repair time to one minute.

Advanced Features

Extended cycles Using the Blu-ray cycle Notes

Your Eco Pro disc repair machine has already been

installed with the Blu-ray software required to repair

Blu-ray discs. Refer to the “Disc Types” section for

more information on the dierences with Blu-ray

discs.

To switch to Blu-ray repairs:

• Press the “FUNC” button. The display will change

from “CD/DVD” to “BD” when in Blu-ray mode.

• Pressing the “START” button twice after closing the

lid, will add an additional minute, extending the total

repair time to two minutes. • The Bluray timings are the same as the standard

timings (30 seconds, 1 minute, 2 minutes, 4 minutes).

• Just press the “START” button repeatedly to

increase the timings.

• Press the “FUNC” button to go back to standard

disc mode.

• Finally, pressing the “START” button three times

after closing the lid, will add an additional two

minutes, extending the total repair time to four

minutes.

Table of contents

Popular Office Equipment manuals by other brands

hushoffice

hushoffice hushtwin HUS-BX-019 Maintenance and safety manual

silen

silen Space 2 Assembly manual

Middle Atlantic Products

Middle Atlantic Products LD Series instruction sheet

SHFL

SHFL DECK MATE BLACKJACK Service manual

VITRA

VITRA Stefan Hürlemann Dancing Wall Assembly instructions

BISLEY

BISLEY Glide V2 Assembly instructions