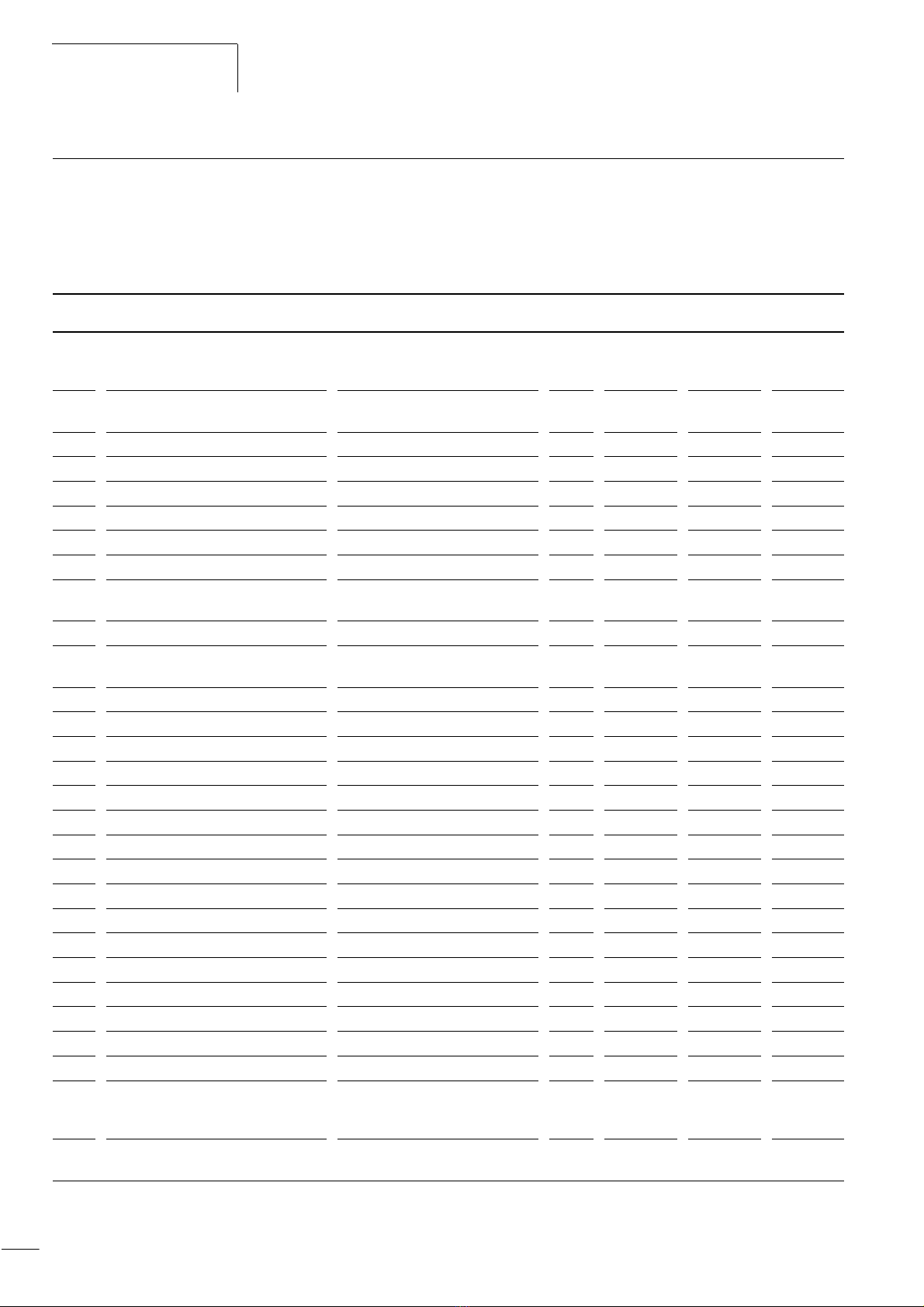

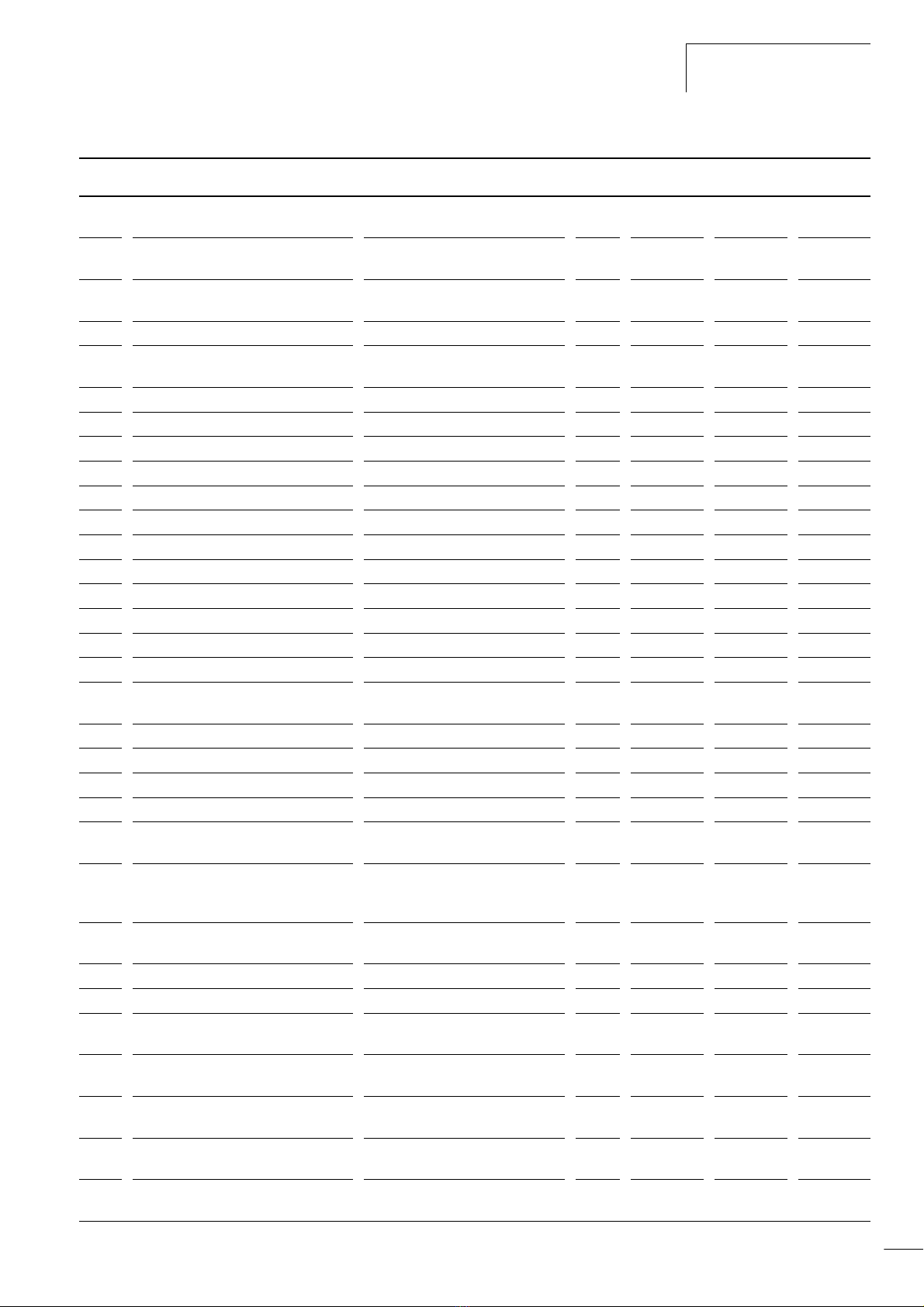

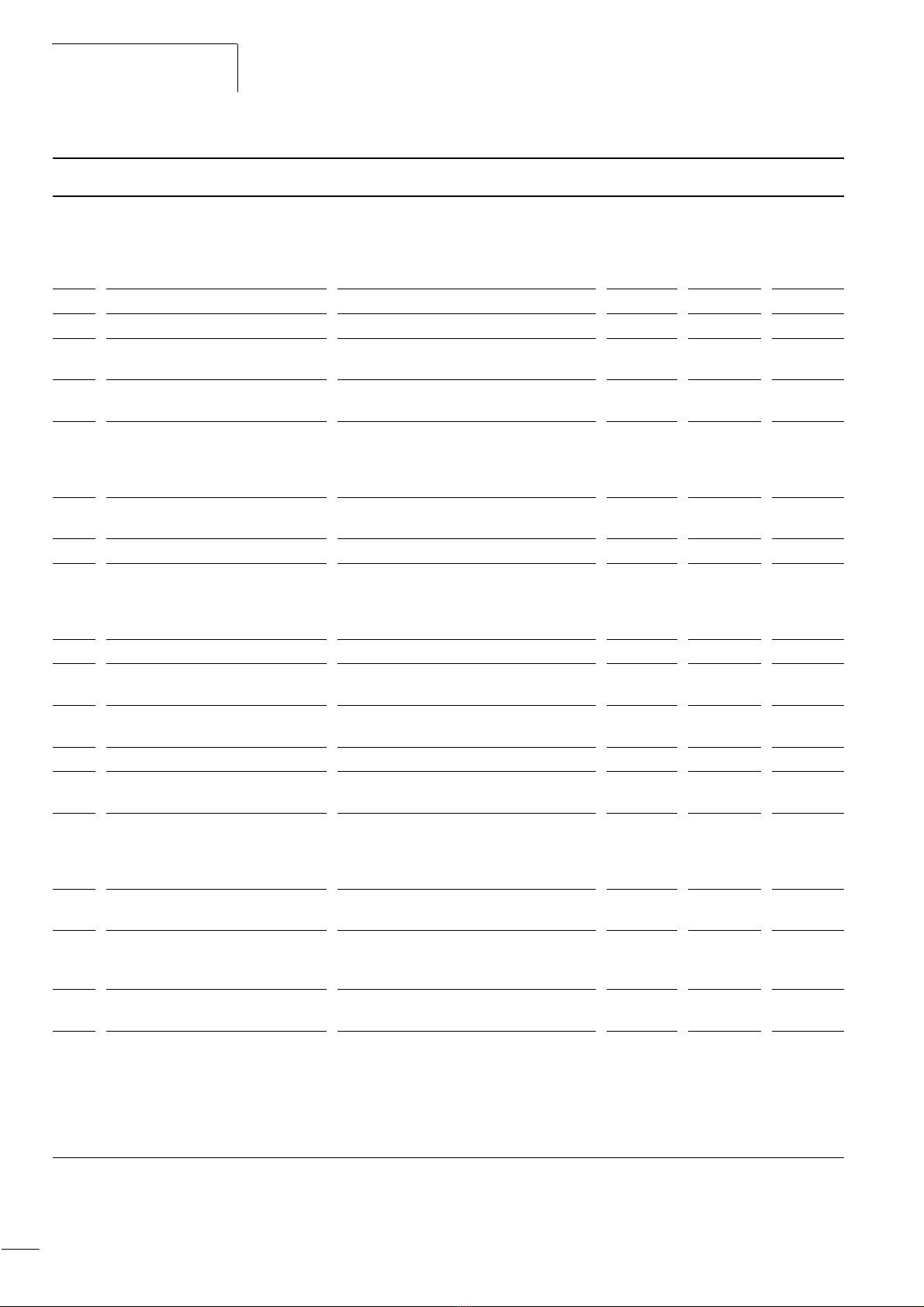

02/02 AWB8230-1447GB Standard form for user defined

parameter settings

9

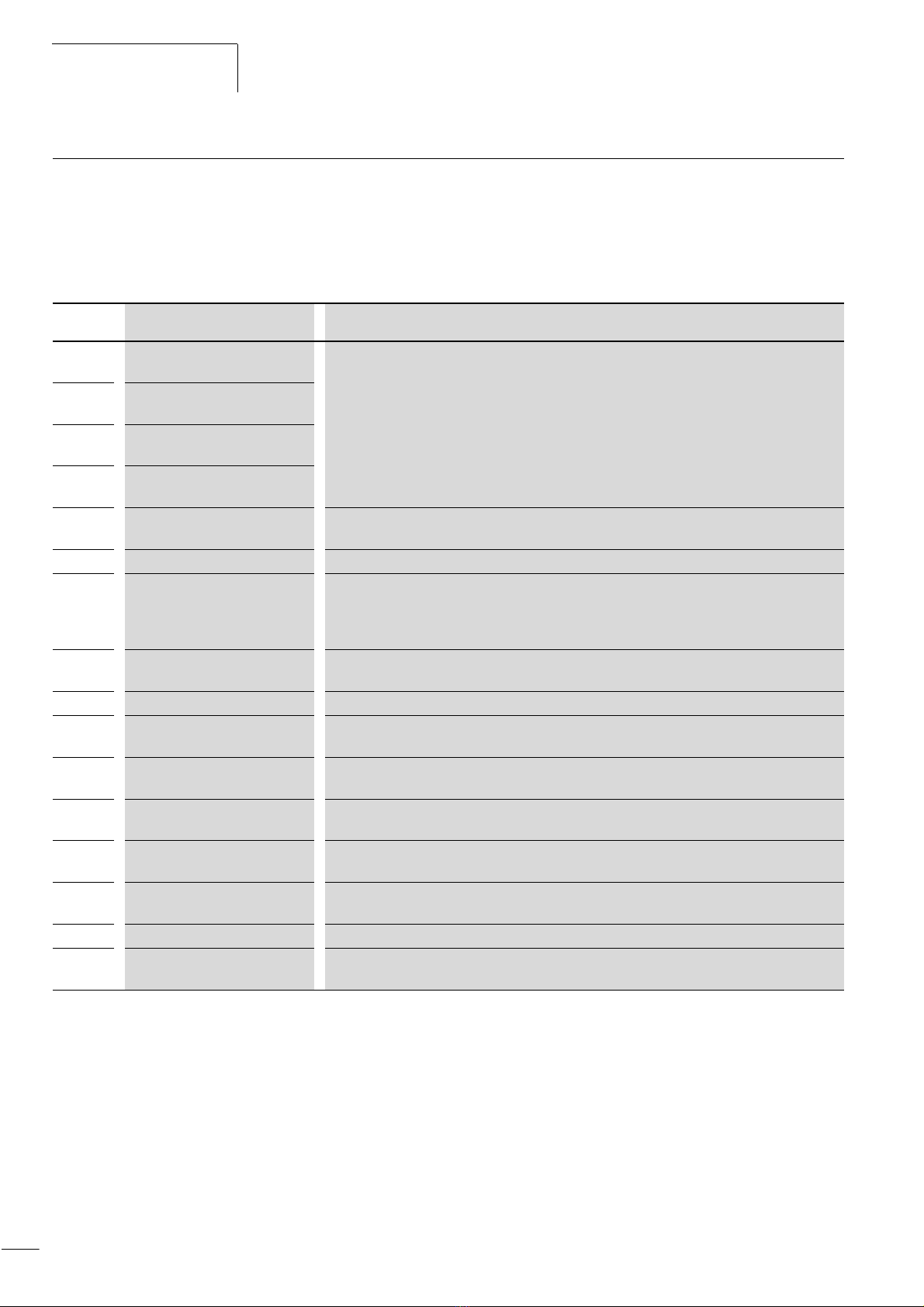

PNU Meaning Value range Def. Setpoint

C01 Function of digital input 1 • 00: FWD, clockwise operation

• 01: REV, anticlockwise operation

• 02: FF1, first fixed frequency input

• 03: FF2, second fixed frequency input

• 04: FF3, third fixed frequency input

• 05: FF4, fourth fixed frequency input

• 06: JOG, jog mode

• 09: 2CH, second time ramp

• 11: FRS, controller inhibit

• 12: EXT, external fault

• 13: USP, unattended start protection

• 15: SFT, parameter protection

• 16: AT, input OI is used

• 18: RST, reset

• 19: PTC, PTC thermistor input

(digital input 5 only)

00

C02 Function of digital input 2 Values aPNU C01 01

C03 Function of digital input 3 Values aPNU C01 02

C04 Function of digital input 4 Values aPNU C01 03

C05 Function of digital input 5 Values aPNU C01 18

C11 Digital input 1 • 00: Make contact

• 01: Break contact

00

C12 Digital input 2 Values aPNU C11 00

C13 Digital input 3 Values aPNU C11 00

C14 Digital input 4 Values aPNU C11 00

C15 Digital input 5 Values aPNU C11 00

C21 Signal on digital output 11 • 00: RUN signal

• 01: FA1, frequency reached

• 02: FA2, frequency exceeded

• 03: OL, Overload

• 04: OD, PID deviation exceeded

• 05: AL, fault

01

C22 Signal on digital output 12 Values aPNU C21 00

C23 Indication through FM output • 00: Frequency, analog

• 01: Motor current, analog

• 02: Output frequency pulse signal

00

C31 Digital output 11 • 00: Make contact

• 01: Break contact

01

C32 Digital output 12 • 00: Make contact

• 01: Break contact

01

C33 Relay output K11-K12 (signalling relay) • 00: Make contact

• 01: Break contact

01

C41 Threshold for overload alarm at digital

outputs 11 and 12

0 to 2 xIe[A] Ie

C42 Frequency from which FA2 is switched on

during acceleration

0 to 360 Hz 0.0

C43 Frequency from which FA2 is switched off

during deceleration

0 to 360 Hz 0.0

C44 PID control deviation (from the maximum

set point value)

0 to 100 % 3.0