2

1.0 Introduction

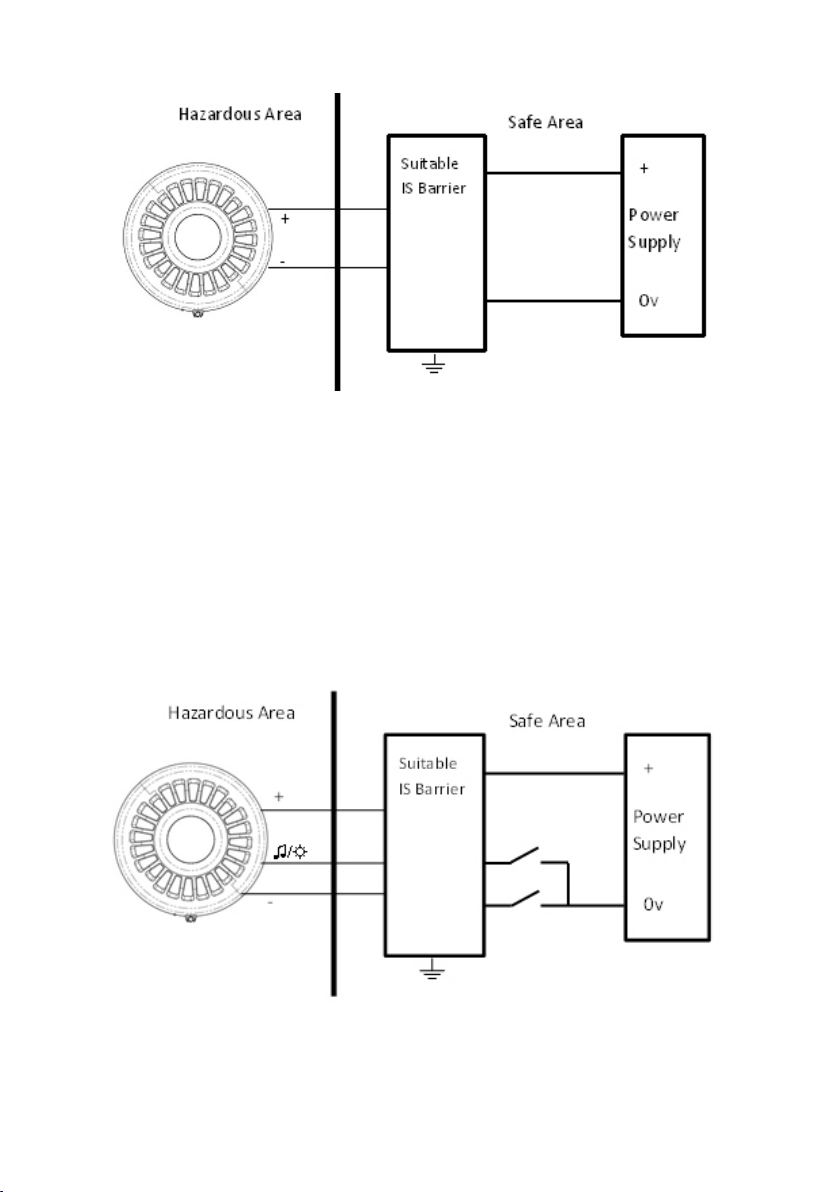

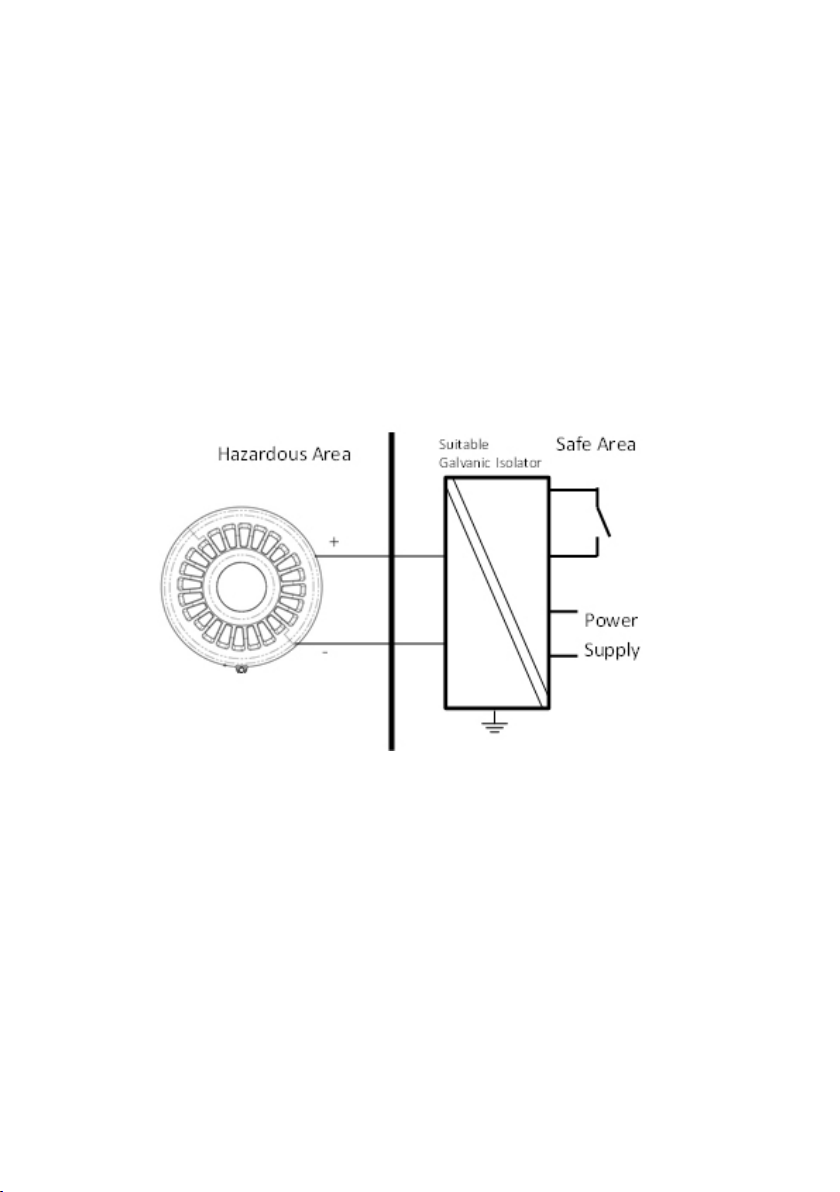

The Moash Intrinsically Safe Sounder product (IS-S-02) is ATEX and IECEx

certied. The Sounder is approved to be installed in Groups I (Mining) and

Group II (above ground), Zones 0, 1 or 2 with gas groups IIA, IIB, IIC and

Zones 20, 21 and 22 for dust groups IIIC and carries a temperature classication

of T6. The Sounder comprises of a 2 stage alarm and has a total of 32 selectable

alarm tones via a DIP switch which is set upon installation. When powered via

a suitable Galvanic Isolator or Zener Barrier the Sounder will draw a constant

33mA. The Sounder has diode reverse polarity protection and is also End of

Line resistor compatible.

2.0 Intrinsically Safe Labelling

The product will have an individual serial number printed onto the head base

plate, an example of the sounder label is shown below.

These products have been tested by notied body Element Materials Technol-

ogy Rotterdam who are UKAS accredited to BS EN ISO/IEC 17025:2005 and

ISO/IEC 17065:2012. It is also a Notied Body for the ATEX Directive, an

IECEx Certication Body and an IECEx Testing Laboratory.

The sufx X at the end of the certicate numbers indicates that there are special

clauses added for safe use of these units.

3.0 Types of Approval and Standards Applied

The Moash IS Sounder product has been approved to the following standards:

IEC 60079-0:2011 / EN 60079-0:2012 + A11:2013

IEC 60079-11:2011 / EN 60079-11:2012

EN 54-3:2001+A1:2002+A2:2006