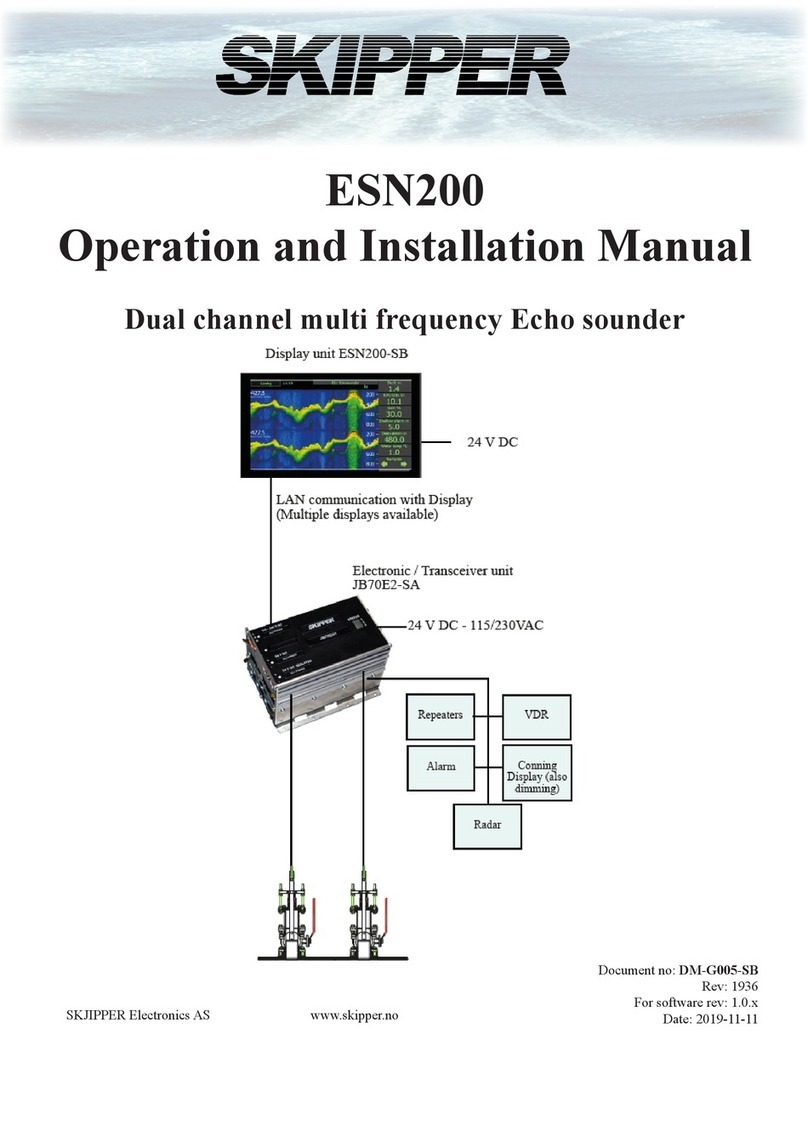

FHF Aiza AX05 User manual

Sounder AX05 and

Sounder-Strobe-Combination AXL05

FHF BA 6031-10 04/11

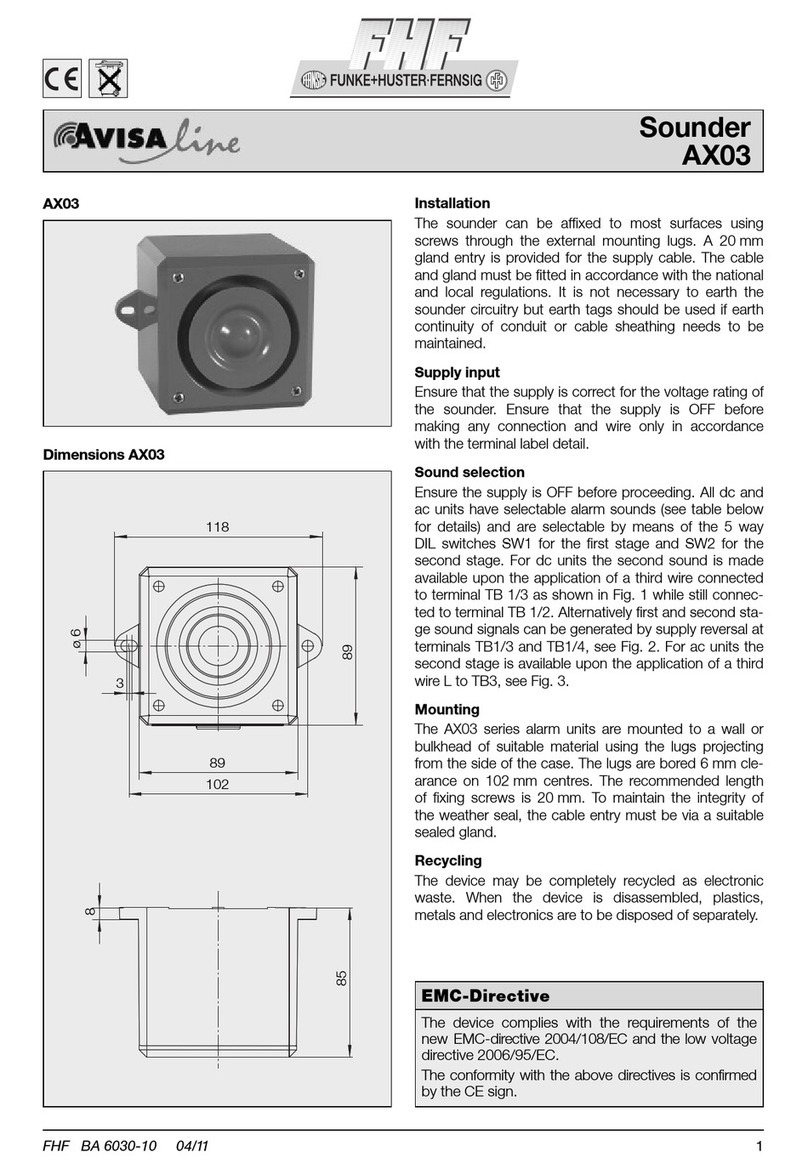

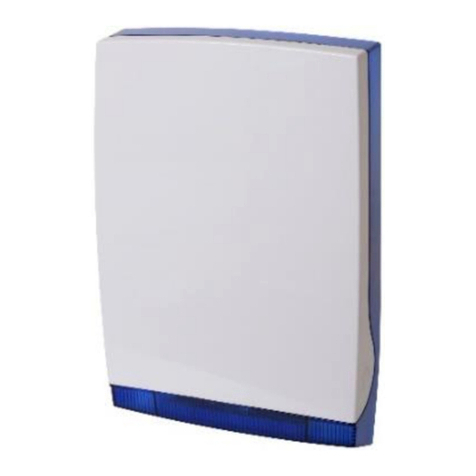

AX05 AXL05

1

Dimensions

AX05

153

134

3

134

ø 8

169

128

9.5

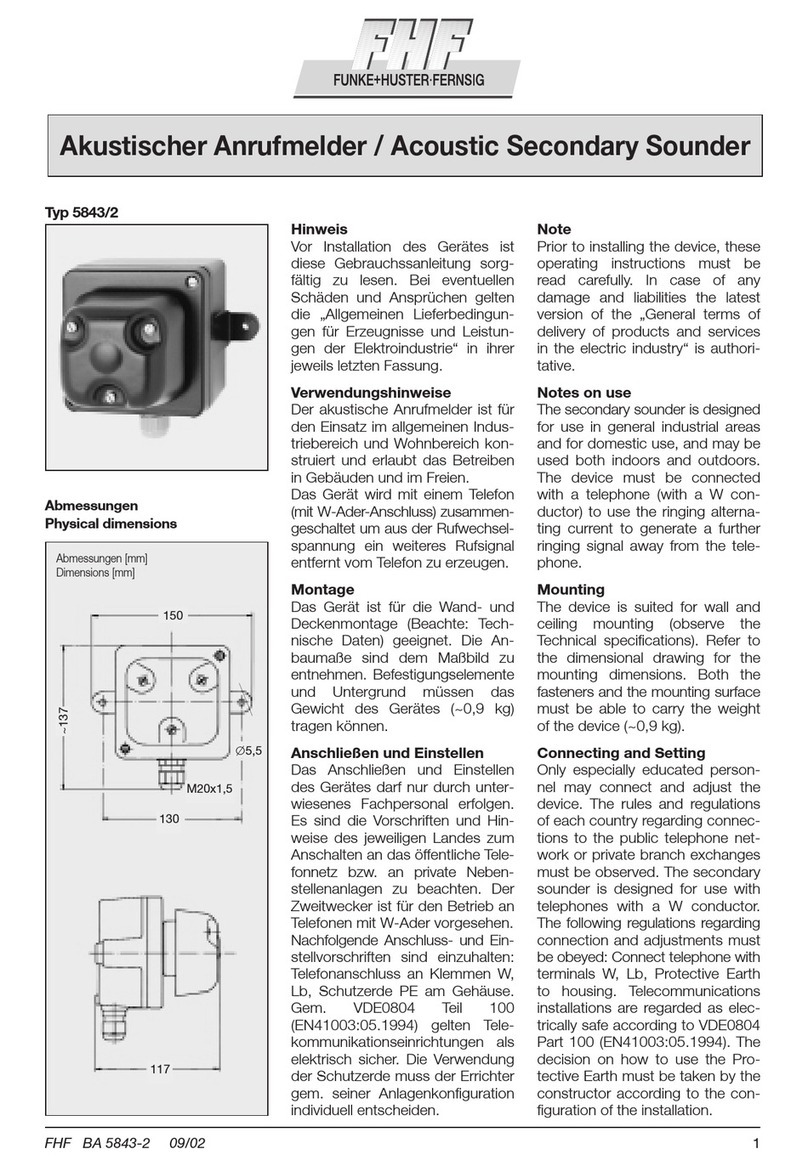

Dimensions

AXL05

169

153

134

134 57.5

ø 8

88

128

9.5

3

2

Housing Polycarbonate

Colour Red, similar to RAL 2002

Insulation class II

Protection degree IP 65 acc. to IEC 60529

Cable gland intended for M20 x 1.5 or Self-sealing grommet

Volume approx. 97-110 dB(A) (depending on signal tone)

Signals 32 different signal tones (see diagrams), 2nd stage can be turned on externally

Temperature range

Operation -25 C to +55 C

Storage -40 C to +70 C

Weight AC 1 kg / DC 0.9 kg

Operating voltage 24 VDC, 115 VAC, 230 VAC

Connecting terminals Clamping capacity 2.5 mm2solid conductor / 1.5 mm2stranded conductor

Flash power 5 J

Cap colours red, yellow, green, blue, clear

Technical Data AXL05

Housing Polycarbonate

Colour Red, similar to RAL 2002

Insulation class II

Protection degree IP 65 acc. to IEC 60529

Cable gland intended for M20 x 1.5 or Self-sealing grommet

Volume approx. 97-110 dB(A) (depending on signal tone)

Signals 32 different signal tones (see diagrams), 2nd stage can be turned on externally

Temperature range

Operation -25 C to +55 C

Storage -40 C to +70 C

Weight AC 0.7 kg / DC 0.6 kg

Operating voltage 24 VDC, 115 VAC, 230 VAC

Connecting terminals Clamping capacity 2.5 mm2solid conductor / 1.5 mm2stranded conductor

Technical Data AX05

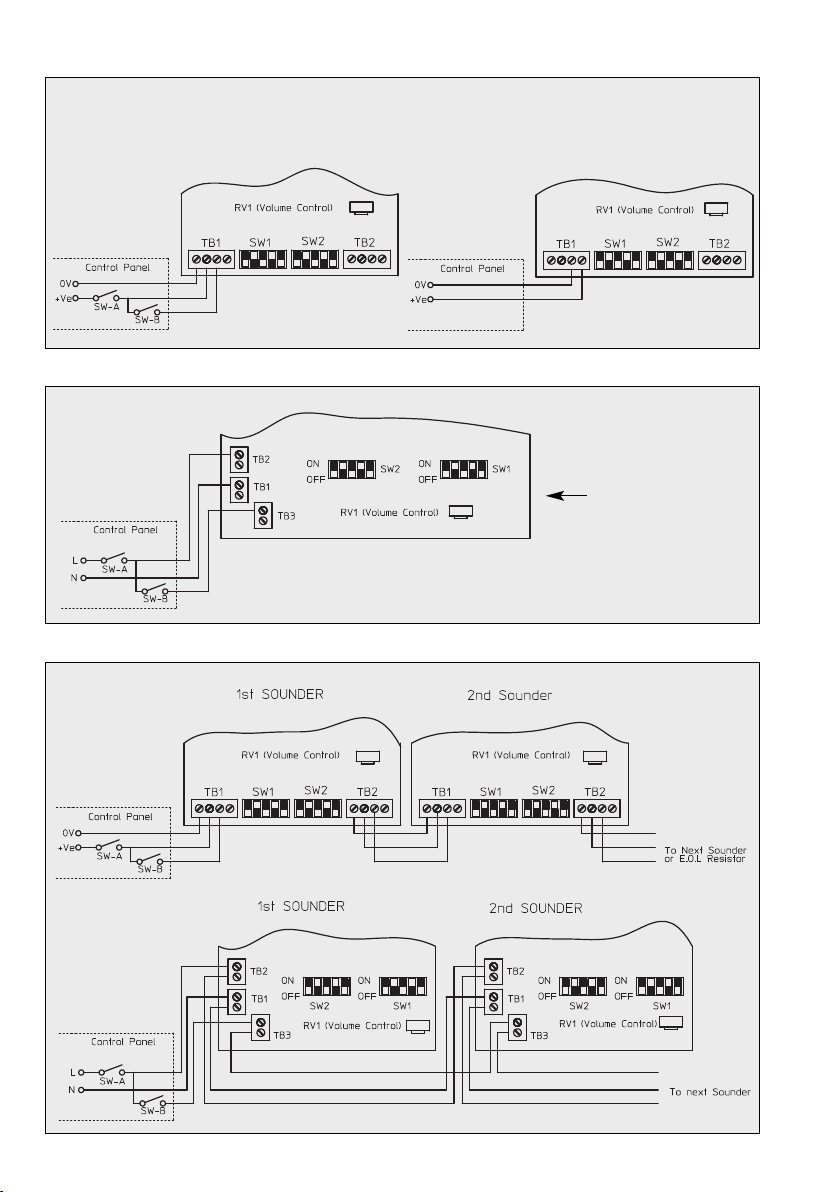

TB1/3 and TB1/4, see Fig. 2. For ac units the second

stage is available upon the application of a third wire L to

TB3, see Fig. 3.

Mounting

The AX05 / AXL05 series alarm units are mounted to

a wall or bulkhead of suitable material using the lugs

projecting from the side of the case. The lugs are bored

8mm clearance on 153 mm centres. The recommended

length of fixing screws is 25 mm. To maintain the integrity

of the weather seal, the cable entry must be via a suitable

sealed gland.

Recycling

The device may be completely recycled as electronic

waste. When the device is disassembled, plastics,

metals and electronics are to be disposed of separately.

Installation

The sounder or combined sounder strobe units can be

affixed to most surfaces using screws through the exter-

nal mounting lugs. A 20 mm gland entry is provided for

the supply cable. The cable and gland must be fitted in

accordance with the national and local regulations. It is

not necessary to earth the sounder circuitry but earth

tags should be used if earth continuity of conduit or

cable sheathing needs to be maintained.

Supply input

Ensure that the supply is correct for the voltage rating of

the sounder or combined sounder strobe being installed.

Ensure that the supply is OFF before making any con-

nection and wire only in accordance with the terminal

label detail.

Sound selection

Ensure the supply is OFF before proceeding. All dc and

ac units have selectable alarm sounds (see table below

for details) and are selectable by means of the 5 way DIL

switches SW1 for the first stage and SW2 for the second

stage. For dc units the second sound is made available

upon the application of a third wire connected to terminal

TB 1/3 as shown in Fig. 1 while still connected to termi-

nal TB 1/2. Alternatively first and second stage sound

signals can be generated by supply reversal at terminals

The device complies with the requirements of the

new EMC-directive 2004/108/EC and the low voltage

directive 2006/95/EC.

The conformity with the above directives is confirmed

by the CE sign.

EMC-Directive

3

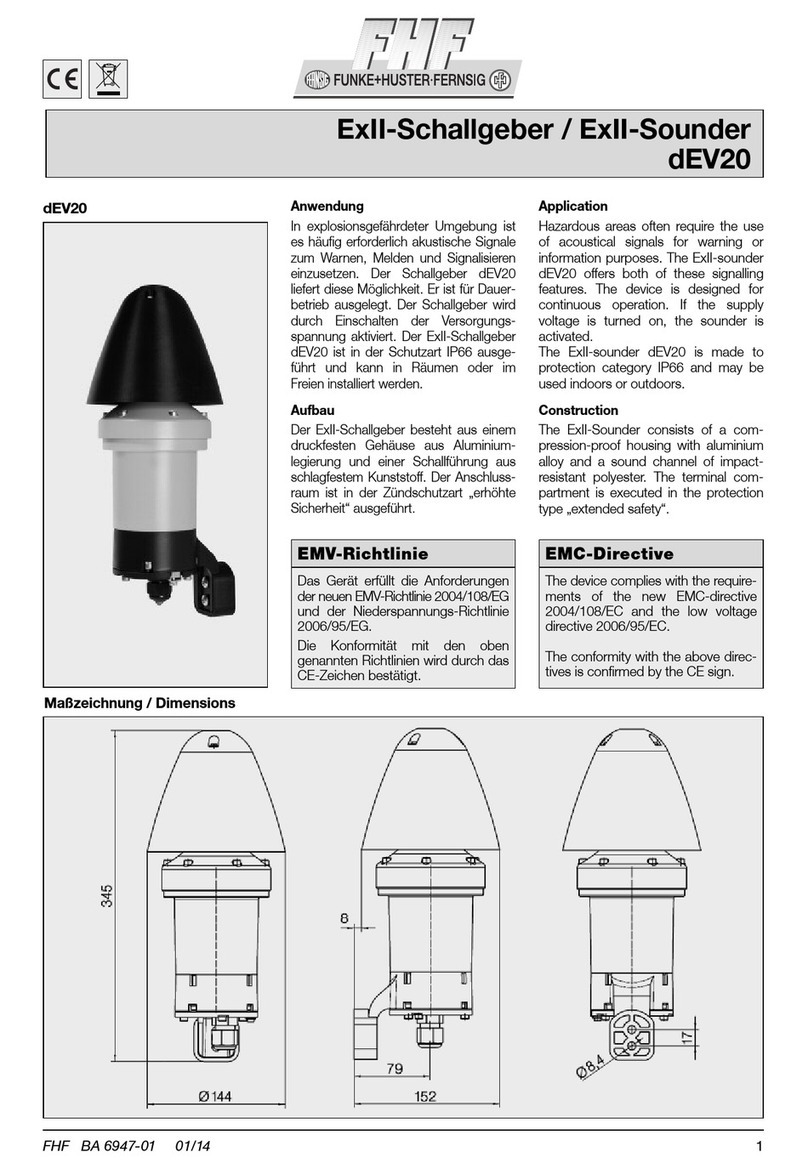

1 Alternate two-tone 800 - 1000 0.5 1 1 1 1 1 Fire Alarms

2 Alternate two-tone 2500 - 3100 0.5 0 1 1 1 1 Security Alarms

3 Alternate fast two-tone 800 - 1000 0.25 1 0 1 1 1 Increased urgency

4 Alternate fast two-tone 2500 - 3100 0.25 0 0 1 1 1 Security deterrent

5 Alternate two-tone 440 - 554 0.4/0.1 1 1 0 1 1 AFNOR, France

6 Alternate two-tone 430 - 470 1.0 0 1 0 1 1

7 Alternate v. fast two-tone 800 - 1000 0.13 1 0 0 1 1

8 Alternate v. fast two-tone 2500 - 3200 0.07 0 0 0 1 1

9 Alternate two-tone 440 - 554 2.0 1 1 1 0 1 Turn-out, Sweden

10 Continuous tone 700 - 0 1 1 0 1 All-clear, Sweden

11 Continuous tone 1000 - 1 0 1 0 1

12 Continuous tone 1000 - 0 0 1 0 1

13 Continuous tone 2300 - 1 1 0 0 1

14 Continuous tone 440 - 0 1 0 0 1

15 Interrupted tone 1000 2.0 1 0 0 0 1

16 Interrupted tone 420 1.25 0 0 0 0 1 AS2220, Australia

17 Interrupted tone 1000 0.5 1 1 1 1 0

18 Interrupted tone 2500 0.25 0 1 1 1 0

19 Interrupted tone 2500 0.5 1 0 1 1 0

20 Interrupted tone 700 6/12 0 0 1 1 0 Pre-vital mess, Sweden

21 Interrupted tone 1000 1.0 1 1 0 1 0

22 Interrupted tone 700 4.0 0 1 0 1 0 Air-raid, Sweden

23 Interrupted tone 700 0.25 1 0 0 1 0 Local warning, Sweden

24 Interrupted tone 720 0.7/0.3 0 0 0 1 0 Industrial alarm, Germany

25 Int. fast rising volume 1400 0.25 1 1 1 0 0

26 Fast siren 250 - 1200 0.085 0 1 1 0 0

27 Rising constant, fall 1000 10/40/10 1 0 1 0 0 Industrial alarm, Germany

28 ISO 8201 Evacuation 800 - 1000 as std 0 0 1 0 0 Int. evacuation alarm

29 Fast whoop 500 - 1000 0.15 1 1 0 0 0

30 Slow whoop 500 - 1200 4.5 0 1 0 0 0 Evacuation, The Netherlands

31 Reverse sweep 1200 - 500 1 1 0 0 0 0 Evacuation, Germany

32 Siren 500 - 1200 3.0 0 0 0 0 0

Switch settings: ON=1 und OFF=0

First and Second Stage Frequency / Rept. Switches Special

Hz rate 2 3 4 5 Application

The PFEER sound signa s recommended by UKOOA are:

General Alarm Sound signal 15 Interrupted tone 1000 Hz

PAPA Sound signal l 31 Reverse Sweep 1200-500 Hz

Toxic gas Sound signal 11 Continuous tone 1000 Hz

Warning: Loud a arm sound. Wear ear defenders when

testing, insta ing and commissioning. High vo tages are

present within the beacon when operationa .

Sound selection table

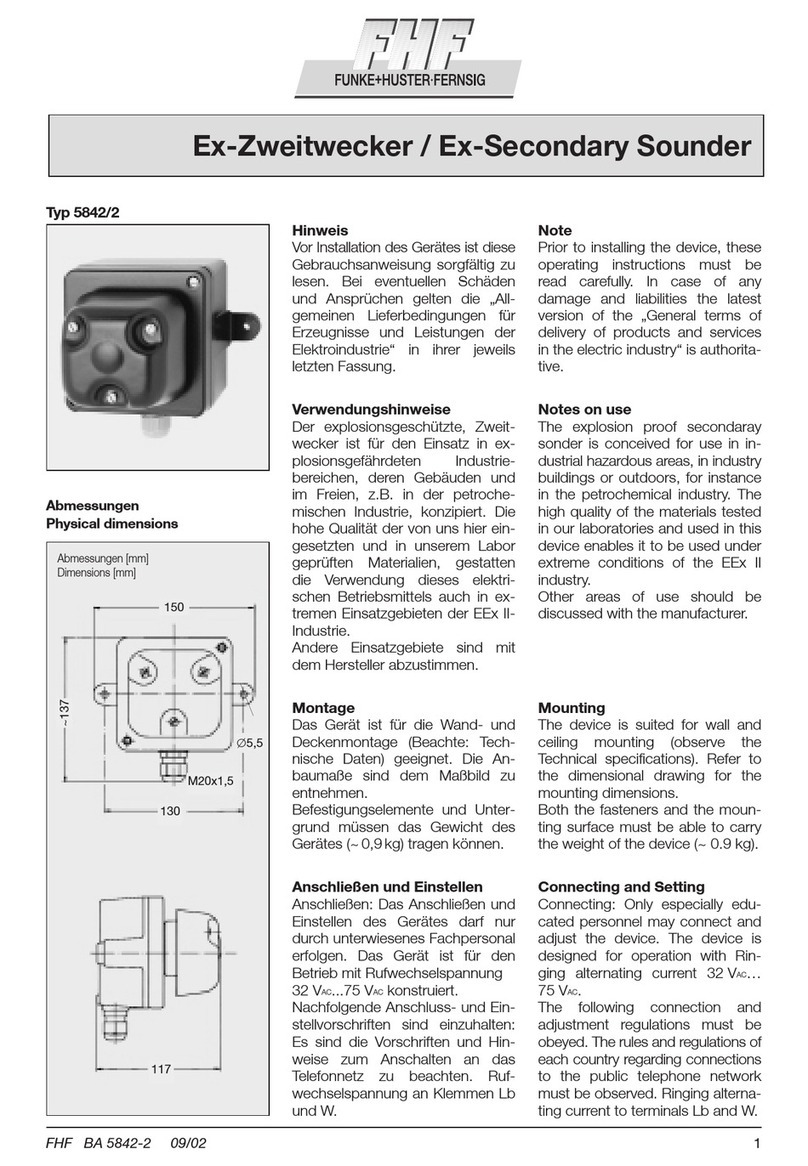

DC Input - second stage with third wire

Line integrity: monitor via reverse polarity

DC Input - second stage by supp y reversa

Line integrity: monitor via threshold (applied voltage ≤ 1 V)

An end-of-line (E.O.L) resistor is required for line monitoring and

it should be a minimum resistance of 3K3 ohms and 0.5 watts.

AC Input

System connection

SOUND SELECTION

4

Figure

Figure 3

Figure 4

Figure 2

Warning: high voltages are present

within the beacon when operational

Wiring detai s for AXL units (opt. /acoust. combination)

User information

1. The appliance has been designed for insulation class II and is only to be connected to, and operated with, the specified

voltage. Specifications of polarity must be observed.

2. Ensure that the casing is not damaged.

3. The relevant codes of Practice an Trade Association requirements for save operation must be observed.

4. Live components may be come exposed when covers are opened or parts are removed. Before opening the appliance

for alignment, maintenance, repair or replacement of parts, the appliance must be disconnected from all power sup-

plies. If it is necessary to carry out alignment, maintenance or repair on the open and live device, this is only to be

undertaken by a qualified specialist who has received corres ponding instruction.

5. Capacitors may still be in a charged state even after the appliance has been disconnected from all power supplies.

6. The appliance is only to be operated under the specified ambient conditions and in the specified mode of operation.

Unfavou rable ambient conditions may cause damage to the appliance and put the user’s life at risk. Unfavou rable

ambient conditions may be:

• excessive air humidity (>75%, relative, condensing)

• moisture, dust (observe protection class)

• flammable gases, vapours, solvents

• excessively high ambient temperatures (>55 C)

7. The ambient temperatures must be within the specified range.

8. The appliance is designed for both indoor and outdoor use.

9. The installation and commissioning of the appliance may only be carried out by a qua lified specialist; the same applies

to any repairs with original spare parts. The use of other than original spare parts may cause damage or injury.

10. The AXL05 has a very intense lighting strength. In order to avoid damage to eyesight, please refrain from looking at

the lamp for any length of time when it is in operation.

5

Figure 5

FHF Funke + Huster Fernsig GmbH

Gewerbeallee 15-19 · D-45478 Mülheim an der Ruhr

Phone +49 / 208 / 82 68-0 · Fax +49 / 208 / 82 68-286

http://www.fhf.de · e-mail: [email protected]

Subject to alterations or errors

This manual suits for next models

1

Table of contents

Other FHF Marine Equipment manuals

Popular Marine Equipment manuals by other brands

allpa

allpa TWIN DISC TECHNODRIVE MC 60 A Service manual

Thales

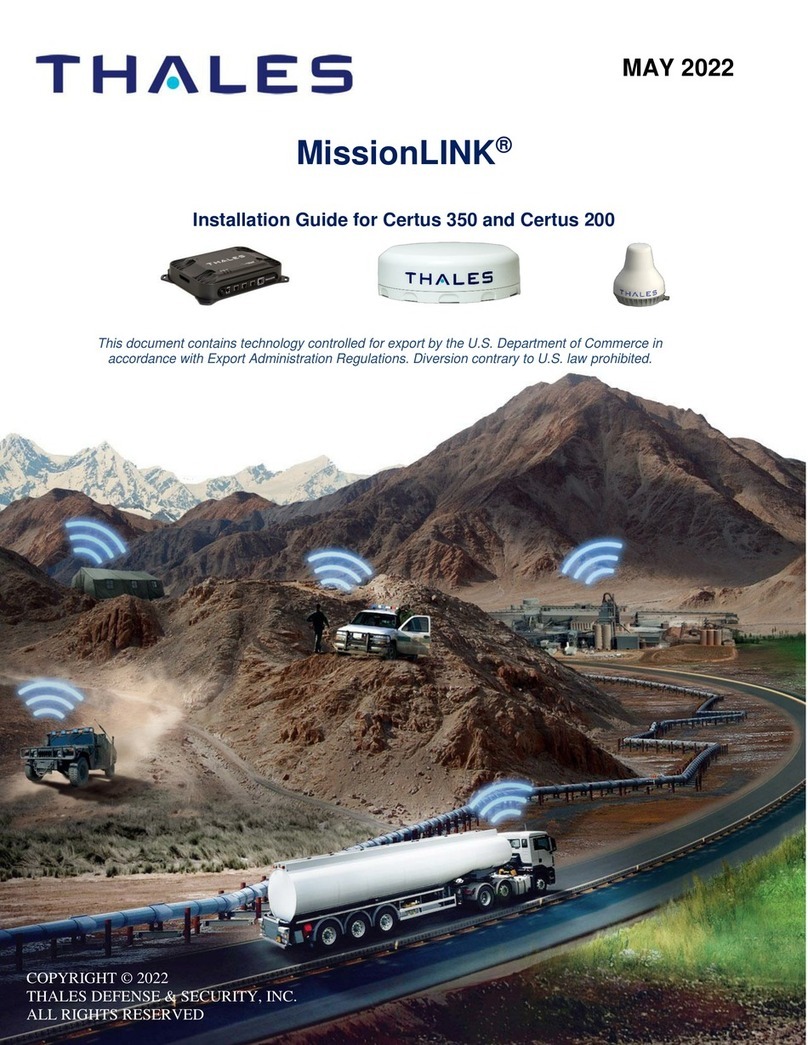

Thales MissionLINK Certus 350 installation guide

B&G

B&G Triton Display installation manual

Alamarin Jet

Alamarin Jet AJ 160 Operation and maintenance manual

INIM

INIM IVY Series Installation and programming manual

Ultraflex

Ultraflex UC 128-TS Installation and maintenance manual

VEXILAR

VEXILAR CLC-200 Operation manual

auto maskin

auto maskin Marine Pro 200 Series Quick installation guide

Raymarine

Raymarine ST60 Plus Rudder quick start guide

Pfannenberg

Pfannenberg PA 130 Operating and installation instruction

Furuno

Furuno ED-222 Operator's manual

Furuno

Furuno TZTBB installation manual