1.0 Introduction

The SB150-1 range is certied for use and installation in Zone 1 and Zone 2

with gas groups IIA, IIB, IIC, also Zones 21 and 22 for Dust. The unit carries a

temperature classication of T4~T6. It especially applies to Oil & Gas, Oshore

Platform, Chemical, Petrochemical, Renery and Marine Industries etc. Enclosure

material is Glass Reinforced Polyester. The sounder has 4 stage alarm tones which

can be sent out. 60 tones are selectable. Tones can be pre-set during installation. At

the same time 4 stages of alarm light can also be sent out.

2.0 Explosion Proof Labelling

All products have a rating label with the following important information:

Product order no: eg SB1501RX05DCNNNAR (Refer to the datasheet for product

order selection)

Input voltage: 12-48v DC or 100-240v AC (50/60 Hz)

Beacon: <25W

Sounder: <20W

Code: Ex d IIC T4~ T6 Gb, Ex tb IIIC T1350C~T850C IP66

Nemko ATEX Certicate No: Nemko 14ATEX 1010X

ATEX Mark:

IECEx Certicate: IECEx-NEM 14.0006X

Gas Group and Category: II 2GD

CE Mark: Mark No: 0891

Warning: DO NOT OPEN WHEN AN EXPLOSIVE GAS

ATMOSPHERE IS PRESENT

Finished product serial no (Include date of construction): ie.08-0001, Year - 08,

product serial no: - 0001.

3.0 Type Approval Standard

The Moash product range all have an EC Type Examination Certicate issued by

Nemko and have been approved to the following standards:

EN 60079-0:2012 (IEC 60079-0:2011), EN-60079-1:2007 (IEC 60079-1:2007)

EN 60079-31:2009 (IEC 60079-31:2008)

8.0 Cable Gland

Only cable glands approved for Exd applications can be used with Moash

Explosion Proof Products, these must be suitable for the type of cable being used and

also meet the requirements of the Exd ameproof installation standard EN 60079-14.

SAFETY WARNING

If units are used at high ambient temperatures, i.e. over +400C then the cable entry

temperature may exceed +700C and therefore suitable heat resisting cable glands

must be used, with a rated service temperature of at least 950C.

If a high IP (Ingress Protection) rating is required, a suitable sealing washer must be

tted under the cable gland. Any unused cable entry holes must be closed with an

Exd ameproof blanking plug, which must be suitably approved for the installation

requirements.

The gland accessories below oer a wide selection to cover most Ex environments

72

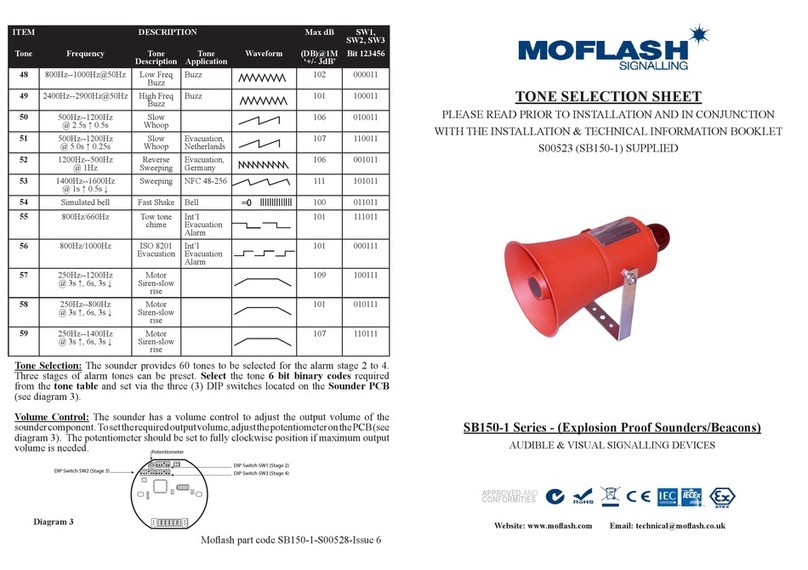

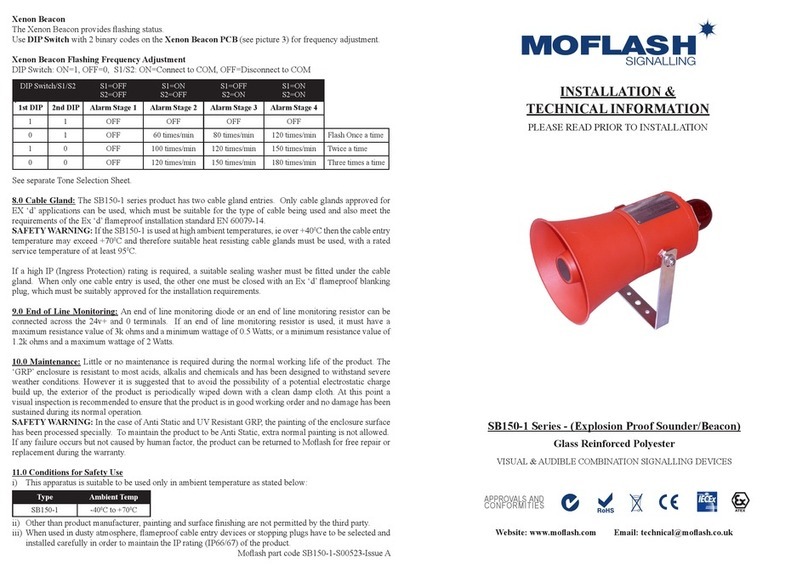

DIP Switch

3 pole - LED

2 pole - Xenon

1 2 3

ON

L SO S2

N S1

FROM

CUSTOMER

Diagram 4

Gland and Plug Options

50200: M20 E1EX Nickel Plated Brass Gland 50210: M20 E1EX Stainless Steel Gland

50201: M20 A2EX Nickel Plated Brass Gland 50211: M20 A2EX Stainless Steel Gland

50202: M20 E1EX-QS Nickel Plated Brass Gland 50212: M20 E1EX-QS Stainless Steel Gland

50203: M20 A2EX Quick Stop Nickel 50213: M20 A2EX Quick Stop

50204: M20 Nickel Plated Brass Stopping Plug 50214: M20 Stainless Steel Stopping Plug