INSTALLATION &

TECHNICAL INFORMATION

PLEASE READ PRIOR TO INSTALLATION

Website: www.moash.com Email: technical@moash.co.uk

APPROVALS AND

CONFORMITIES

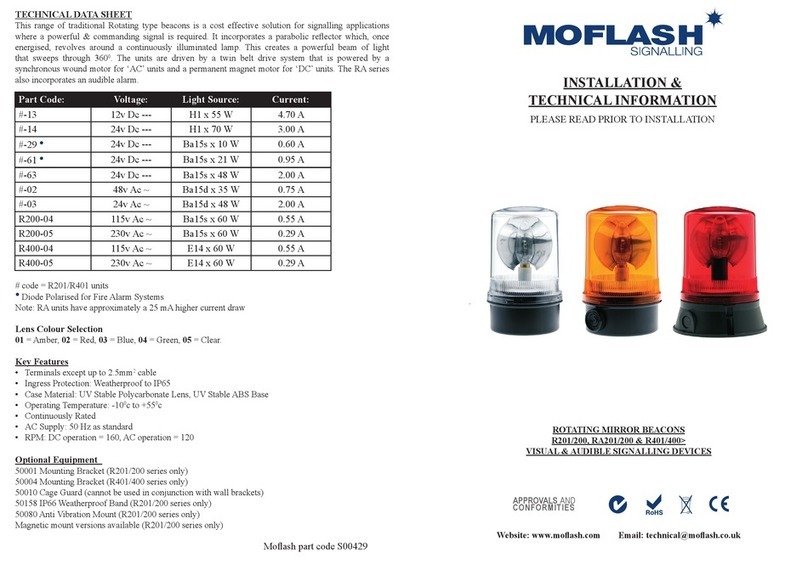

TECHNICAL DATA SHEET

This range of beacons incorporates a 144 o LED array that emits its light through 360o

around the vertical axis. They have a choice of four modes of alarm that are pre-set via a

two-way dip switch located under the lens. To maintain the ingress protection of the enclosure the

lens should always be mounted above the base. The 201/200 series is suitable for surface, conduit

box or wall mounting. The LED401/400 is suitable for surface or wall mounting.

For Lens colours add: -01 Amber, -02 Red, -03 Blue, -04 Green, -05 Clear

Key Features Include:

Note: The 201/200 series has the ability to be used in a ‘loop in’ ‘loop out’ daisy chain

application using the terminals provided, however the wire size must not exceed 2.5mm2.

• Connection terminals except upto 2.5mm2 cable

• Multi Voltage high volt options

• Operating Temperature -25oc to +55oc

• Case Material is UV Stable Polycarbonate & UV Stable ABS

• Weatherproof to IP65

• AC = 50/60 Hz

Optional Equipment:

• 50004 Mounting Bracket

• 50010 Cage Guard (cannot be used in conjunction with mounting bracket)

• 50080 Anti Vibration Mount (201/200 Series)

Moash part code S00418 Issue 3

LED201/200 & LED401/400 Series - (LED Array)

MULTI-FUNCTIONAL VISUAL SIGNALLING DEVICES

Part Code: Voltage: Colours Current:

Flashing Rotating Static

LED201-02 24v Dc --- Red & Amber 210mA 130mA 440mA

Green, Blue & Clear 115mA 50mA 230mA

LED200-04 •90-370v Dc ---

70-265v Ac ~

Red & Amber 110/55mA 50/25mA 200/100mA

Green, Blue & Clear 65/40mA 27/20mA 120/59mA

LED401-02 24v Dc --- Red & Amber 210mA 130mA 440mA

Green, Blue & Clear 115mA 50mA 230mA

LED400-04 •90-370v Dc ---

70-265v Ac ~

Red & Amber 110/55mA 50/25mA 200/100mA

Green, Blue & Clear 65/40mA 27/20mA 120/59mA

• Current @ 115/230v Ac ~

• Current @ 280v Dc ---

Amber/Red in Static Mode is 40mA

All Models Pre-set to Flash Mode

2 Bar Rotating