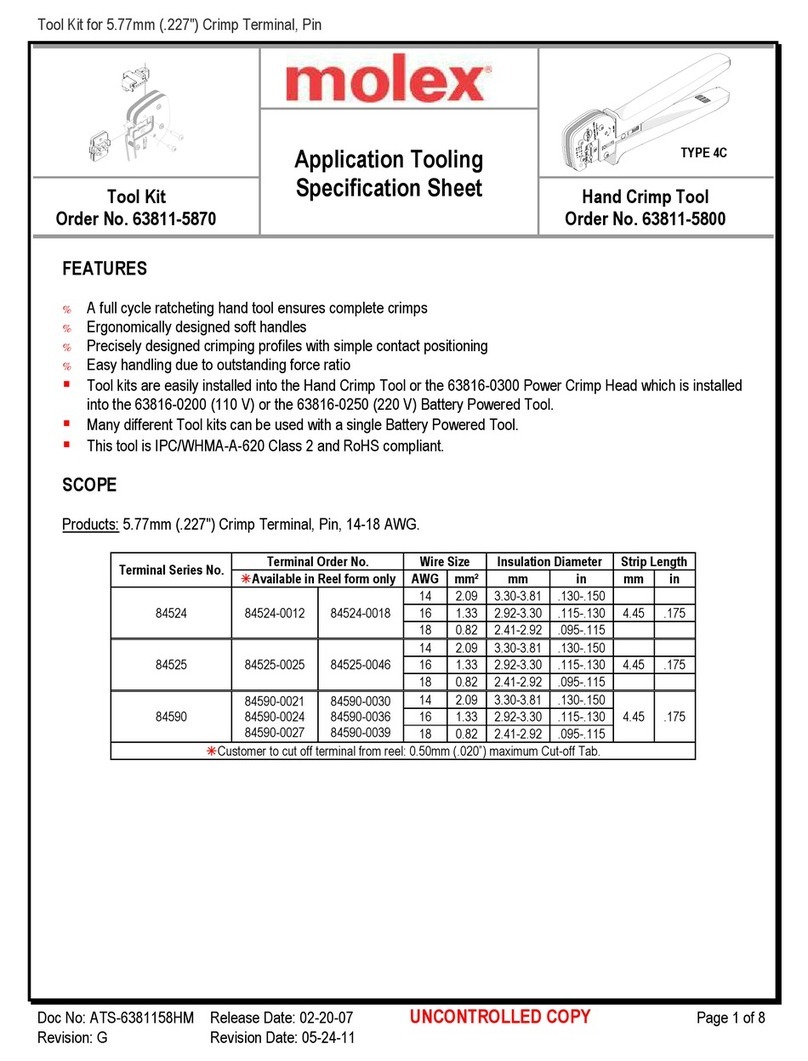

Tool Kit for MLX150L™ Crimp Terminals

Doc No: ATS-6 8115 HM Release Date: 04-29-05 UNCONTROLLED COPY Page 4 of 8

Revision: C Revision Date: 09-07-10

4. Remove the crimp terminal from the terminal locator by pressing the tab on the wire stop and gently pulling on

the wire.

5. Visually inspect the crimped terminal for proper crimp location and crimp height.

For th Batt ry Pow r Tool:

1. Cycle the Battery Power Tool to crimp the terminal to the wire.

2. Remove the crimped terminal from the terminal locator by pressing down on

the wire stop and gently pulling on the wire. The terminal locator can be in

either position.

. Visually inspect the crimped terminal for proper crimp location.

Not :

A crimp height chart is provided with this manual as Reference Only. Due to the

wide range of wires, strands, insulation diameters, and durometers, actual crimp

height measurements may very slightly. An occasional, destructive, pull force test

should be preformed to check hand tool crimp. Pull Force value must exceed the

minimum pull force specifications listed.

Maint nanc

It is recommended that each operator of the tool be made aware of,

and responsible for, the following maintenance steps:

1. Remove dust, moisture and other contaminants with a clean

brush, or soft, lint-free cloth.

2. Do not use any abrasive materials that could damage the tool.

. Make certain all pins; pivot points and bearing surfaces in the

tool head are protected with a thin coat of high quality machine

oil. Do not oil excessively. This tool was engineered for

durability, but like any fine piece of equipment, it needs

cleaning and lubrication for a maximum service life of trouble-

free crimping. The use of light oil, such as 0 weight

automotive oil, every 5,000 crimps or monthly, will significantly enhance the tool life and ensure a stable

calibration. See Figure 6A or 6B for lubrication points.

4. Store the tool in a clean and dry area when not in use.

Miscrimps or Jams for Crimp Hand Tools Only

(S Figur 9)

Should this tool ever become stuck or jammed in a partially closed position, Do Not force the handles open or

closed. The tool will open easily by rotating the small slotted screw marked with an arrow. See Figure 9.

Warranty

This tool kit is for electrical terminal crimping purposes only. This tool kit is made of the best quality materials. All

vital components are long life tested. All tools are warranted to be free of manufacturing defects for a period of 0

days. Should such a defect occur, we will repair or exchange the tool kit free of charge. This repair or exchange

will not be applicable to altered, misused, or damaged tools.

LUBRICATION

POINTS

(BOTH SIDES)

LIGHT OIL

(EVERY MONTH

OR

5,000 CRIMPS)

Figur 6A

LUBRICATION POINTS

(BOTH SIDES) LIGHT OIL

(EVERY 3 MONTHS OR

5,000 CRIMPS)

Figur 6B