molex 207129 Series User manual

Other molex Crimping Tools manuals

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

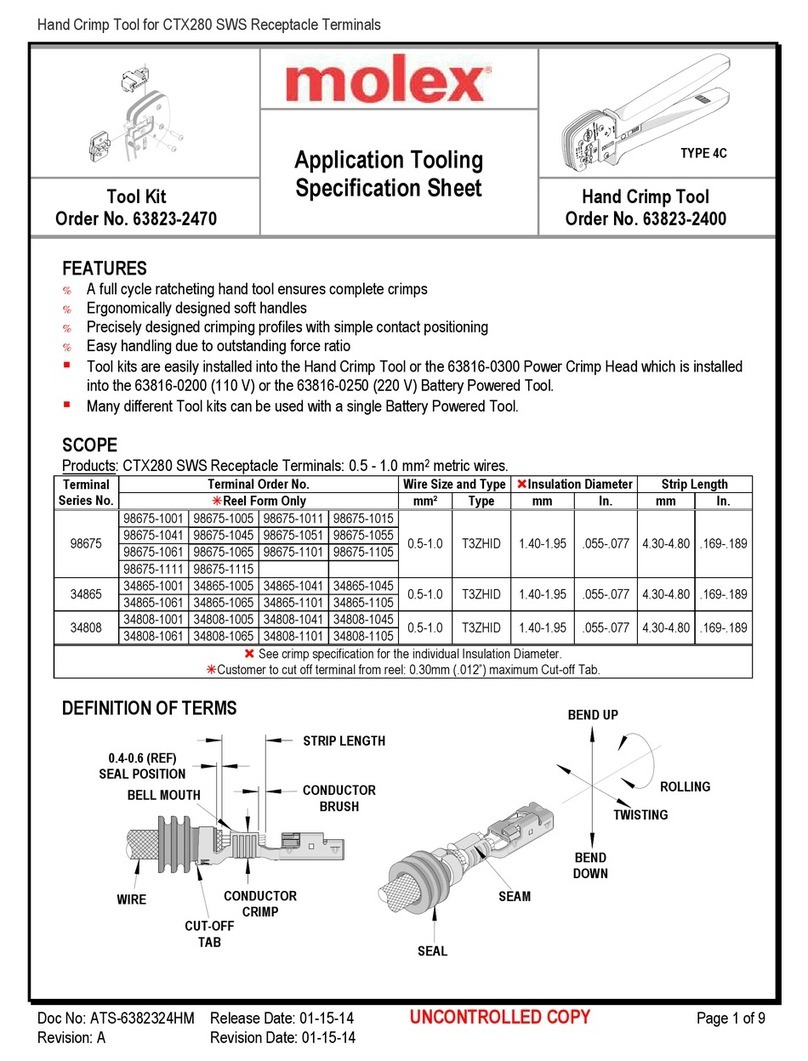

molex 64001-7400 User manual

molex

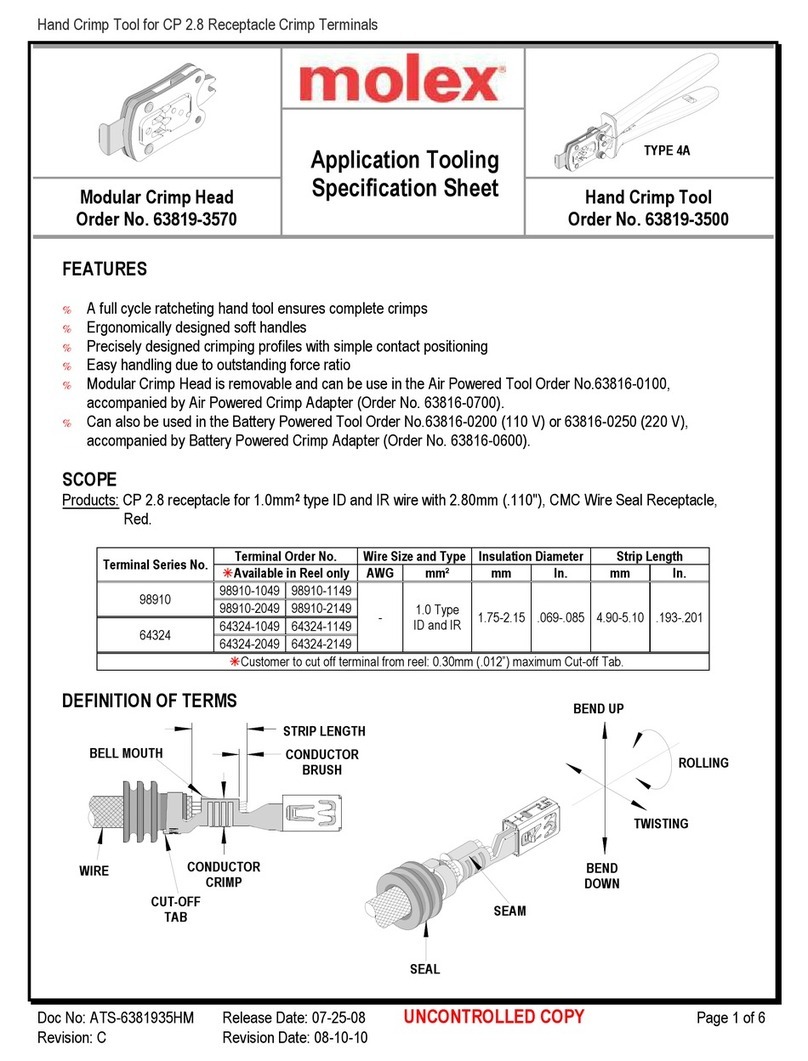

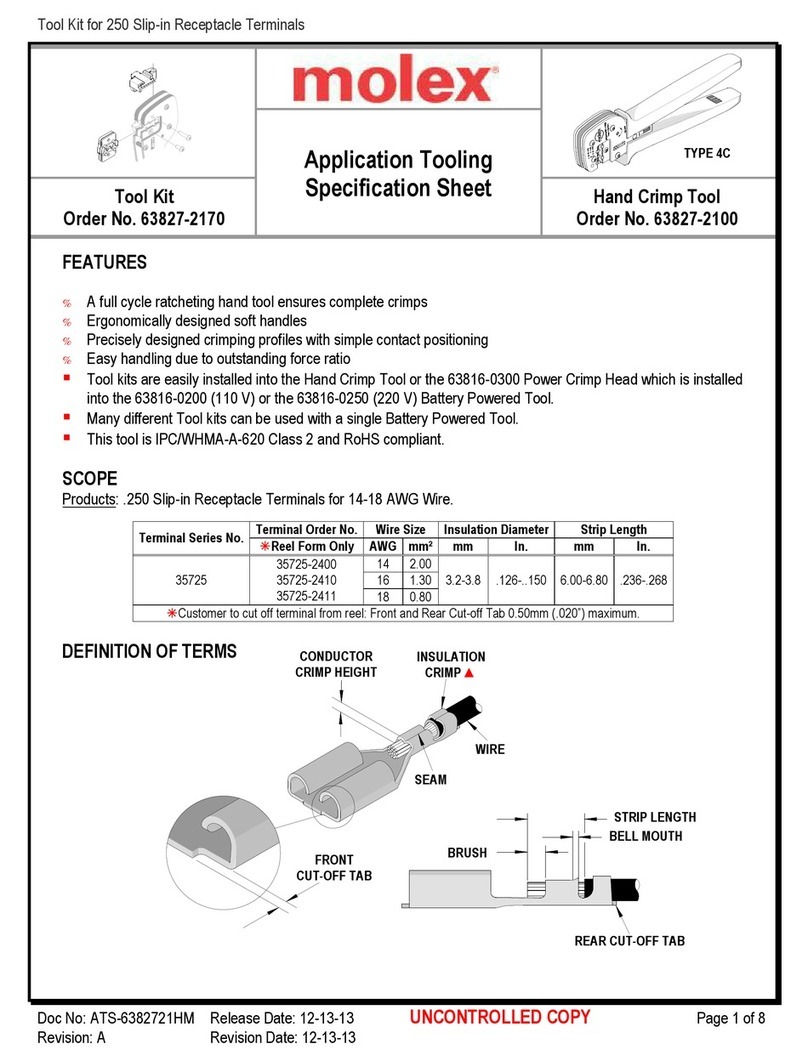

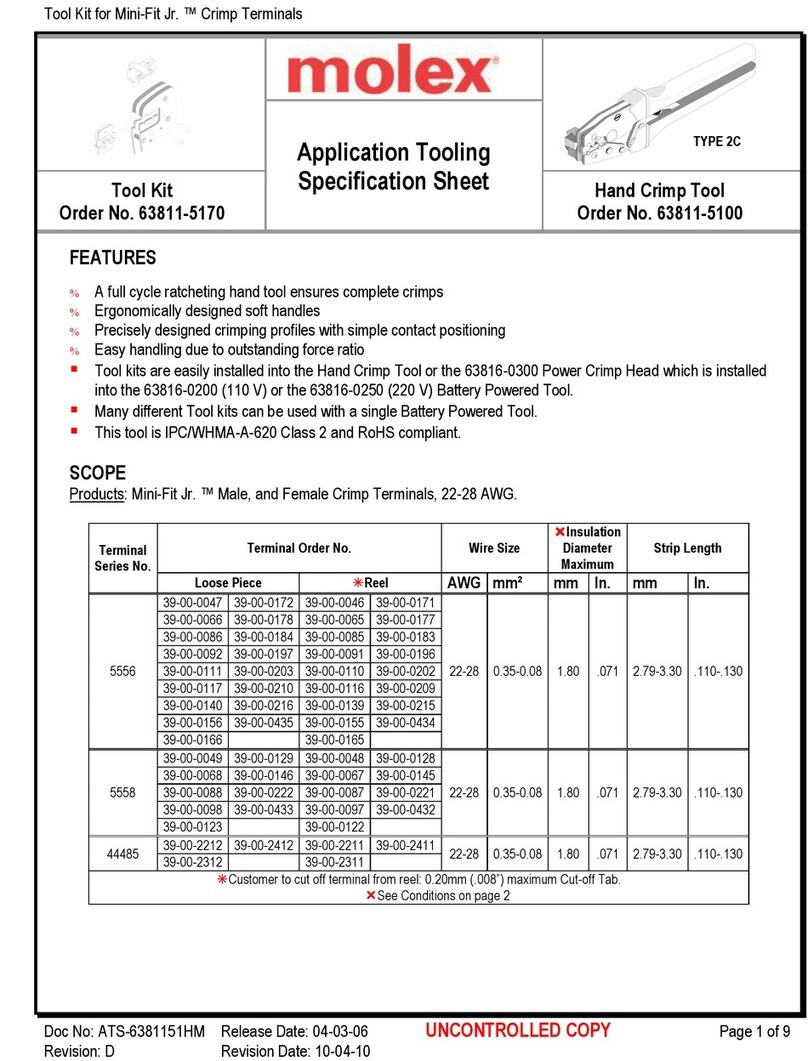

molex 63827-2100 User manual

molex

molex 4D User manual

molex

molex 207129 Series User manual

molex

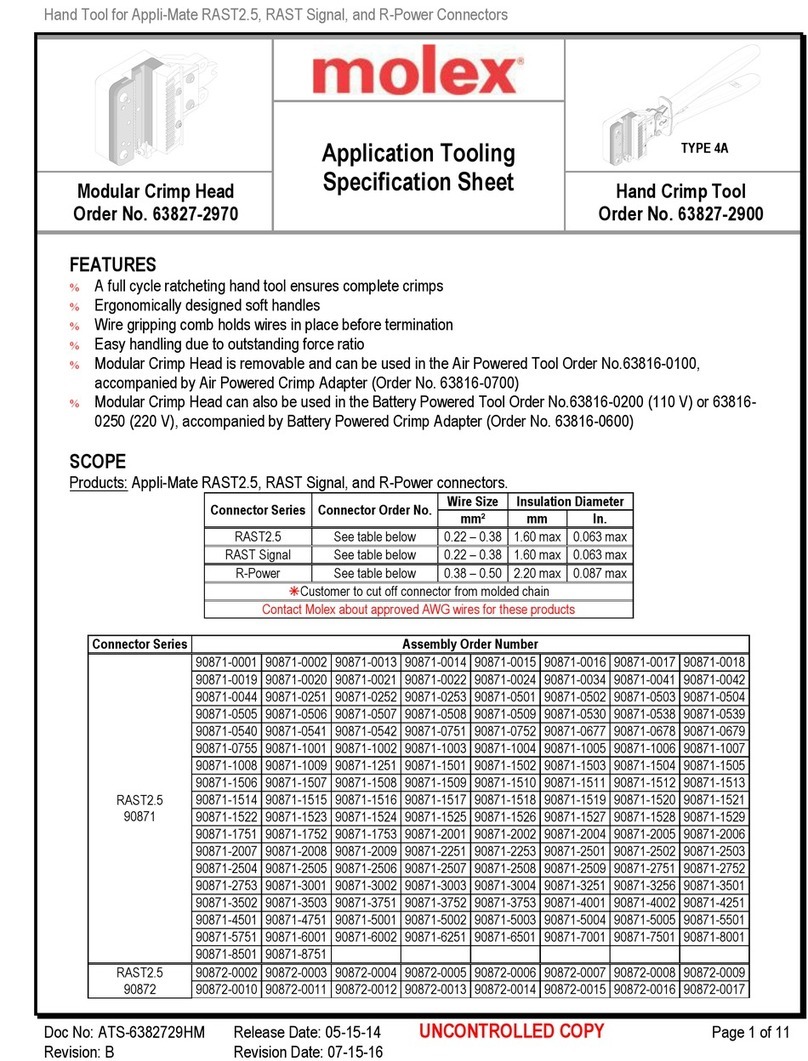

molex 63827-2970 User manual

molex

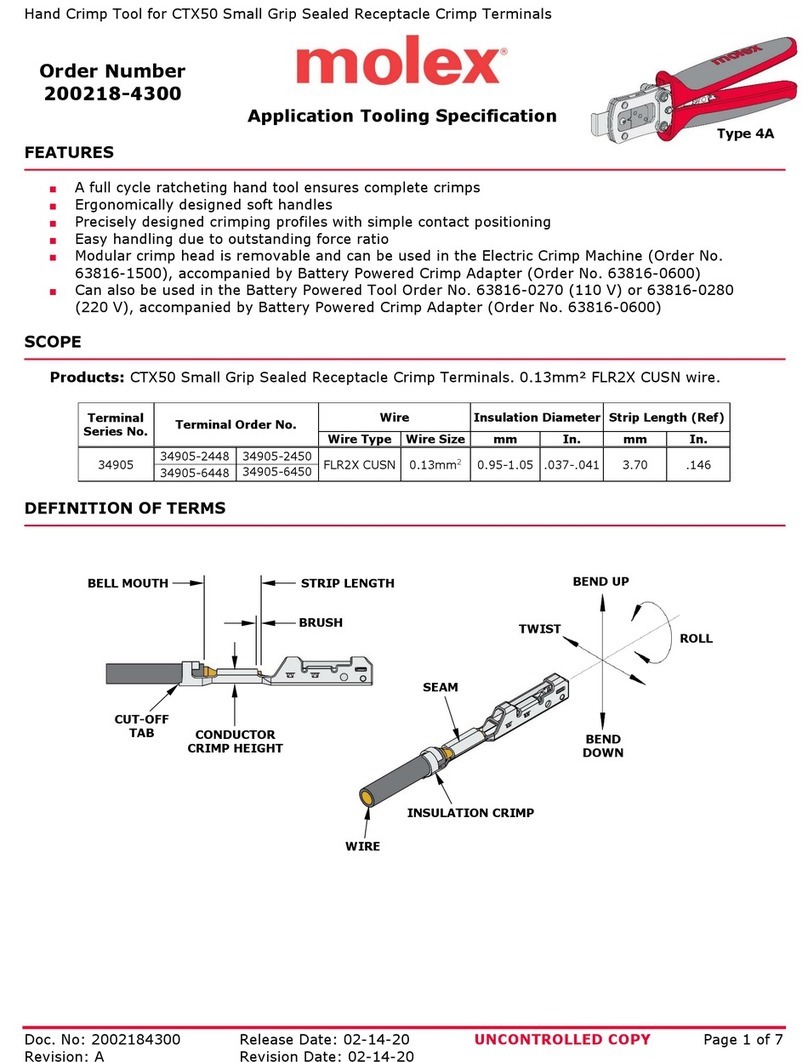

molex CR5905 User manual

molex

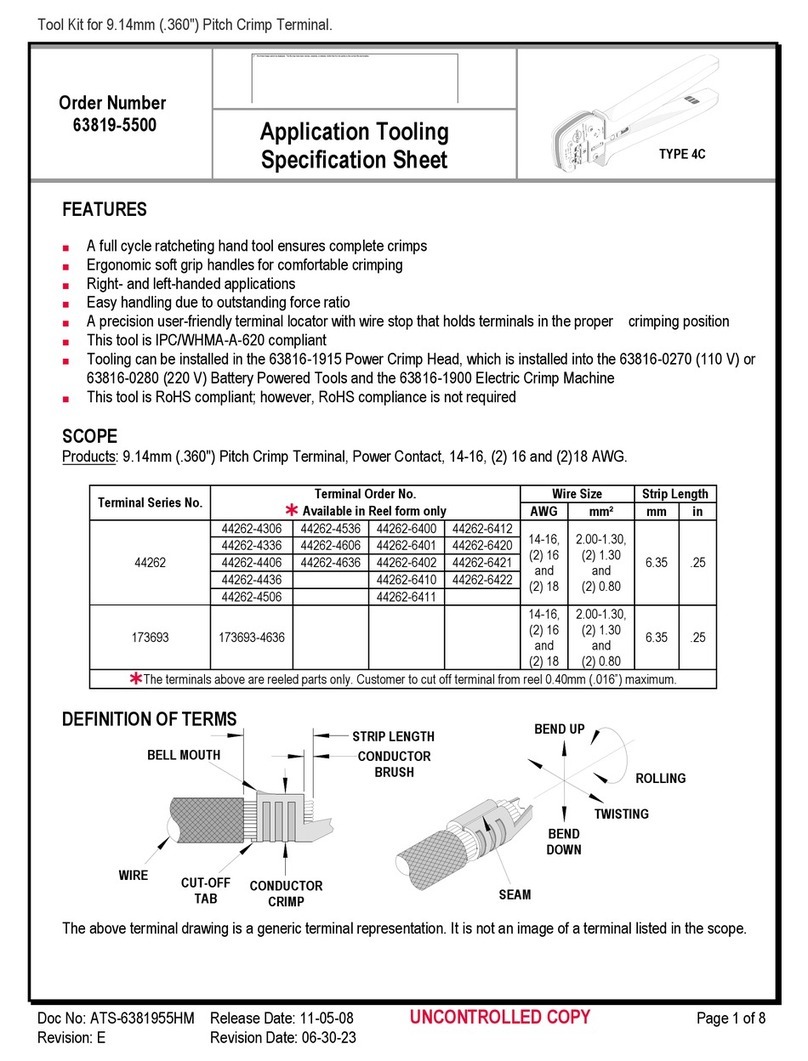

molex 44262-4306 User manual

molex

molex 207129 Series User manual

molex

molex CR1031E User manual

molex

molex 35745 Series User manual

molex

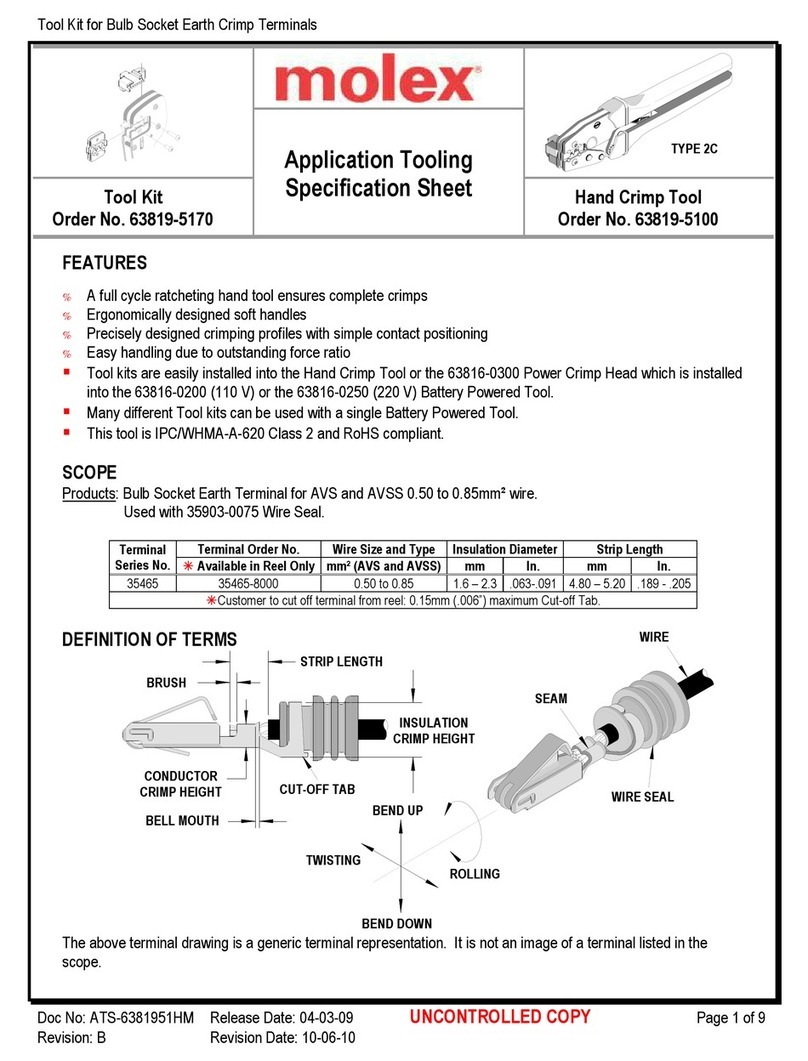

molex 35465 Series User manual

molex

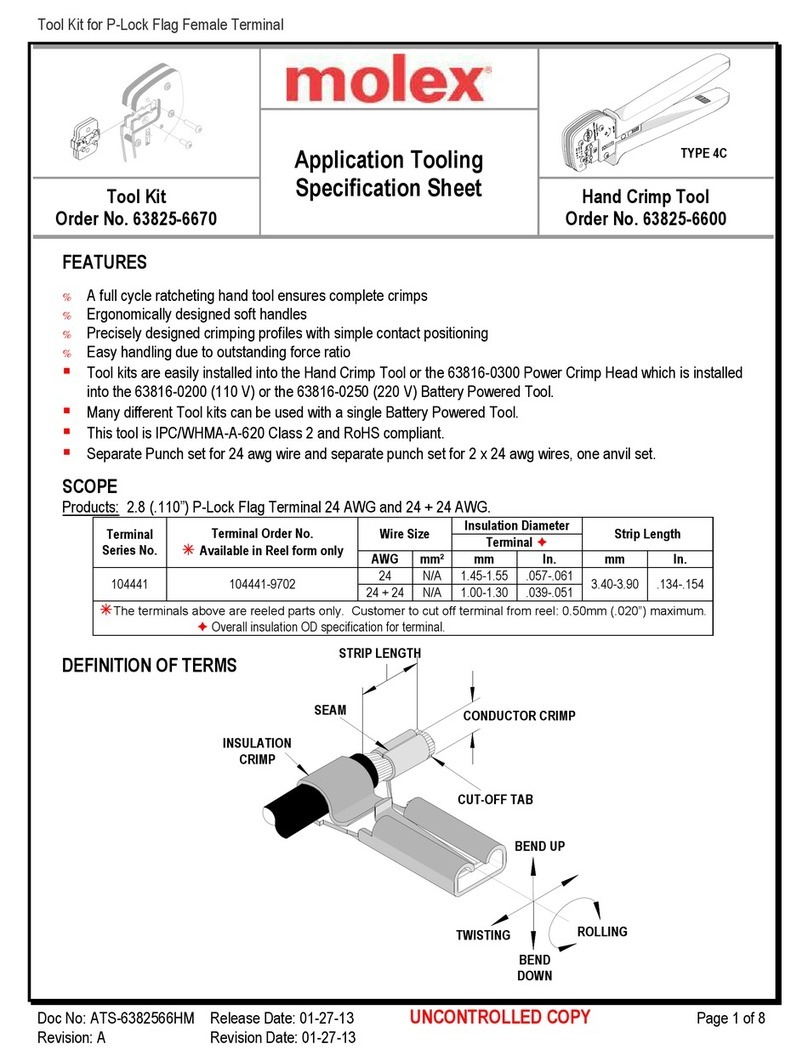

molex 63825-6670 User manual

molex

molex 35745 Series User manual

molex

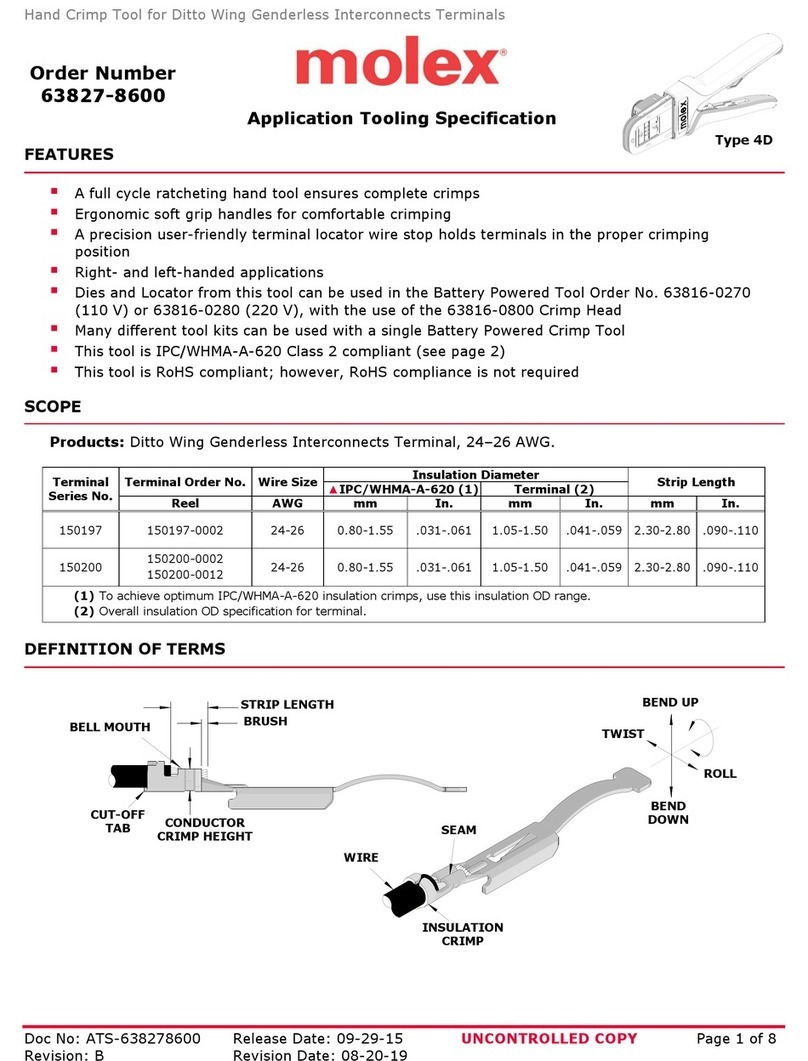

molex 63827-8600 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 63827-5470 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet