AS.04.03.15/ Issue C

FILENAME:SD-69008-0250b

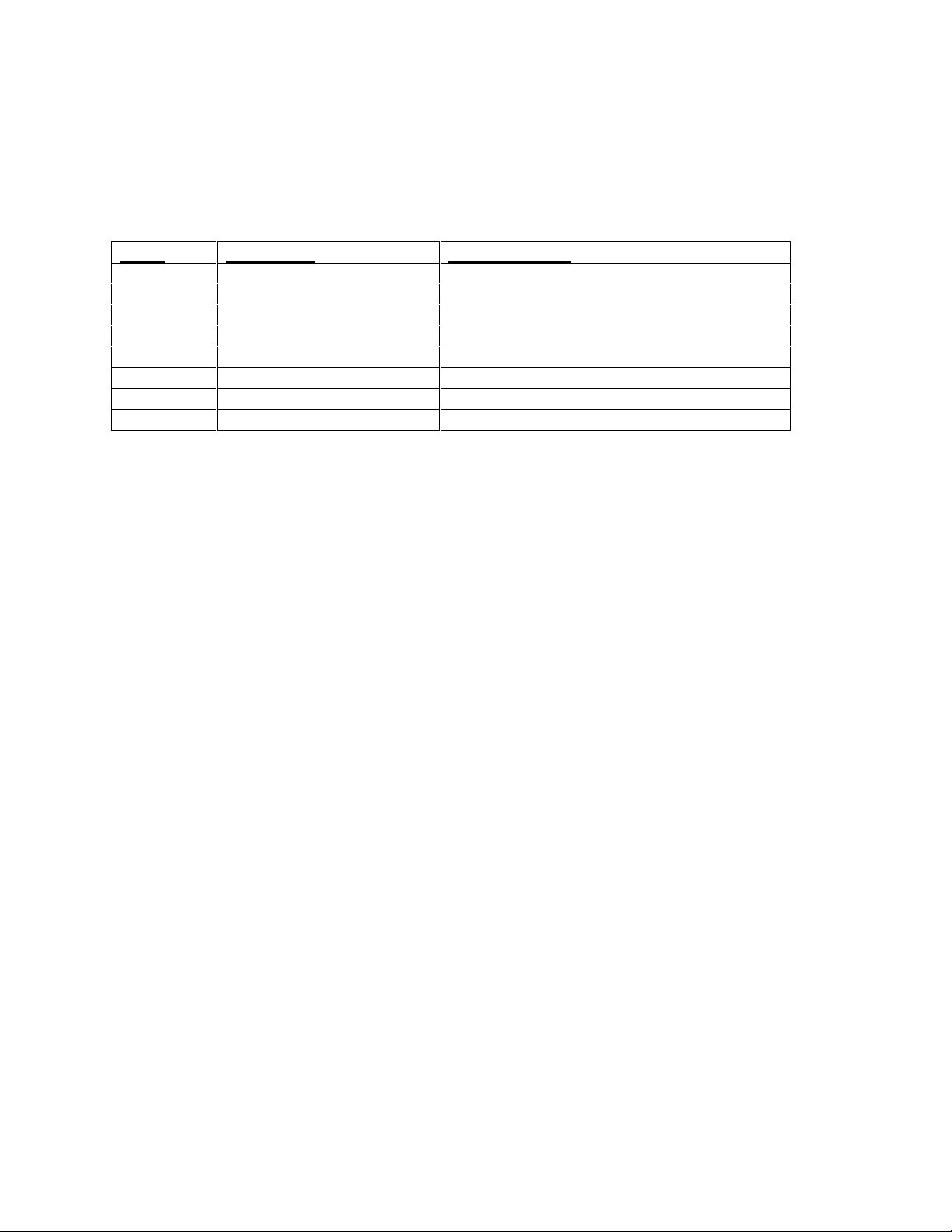

PARTS LIST FOR CHANGEHEAD

Item Part No. Description

1 69008-0250 Changehead

2 69008-0251 Body Moulding

3 69008-0252 Cover Plate

4 69008-0253 Pressure Part

5 69008-0254 Spring

6 69008-0255 Locator

7 69018-7048 Bush

ADJUSTMENTS

TERMINATION DEPTH

To adjust termination depth of connector, remove the changehead

from the pistol. A small screw can be seen in the mounting slot

rotate clockwise to decrease insertion depth.

PISTOL 69008-0949

This tool is factory set to give a stroke of 11.7mm and does not

need adjusting.

QUALITY

Check termination quality against the Molex wire termination

specification for relevant product being terminated eg: PS-90650.

A quality procedure should be in place to monitor output from

this changehead.

SAFETY

This pistol changehead should be used in accordance with the

operation procedure. Any misuse may cause injury to operator.

Suitable training should be given to indicate good working

practice.