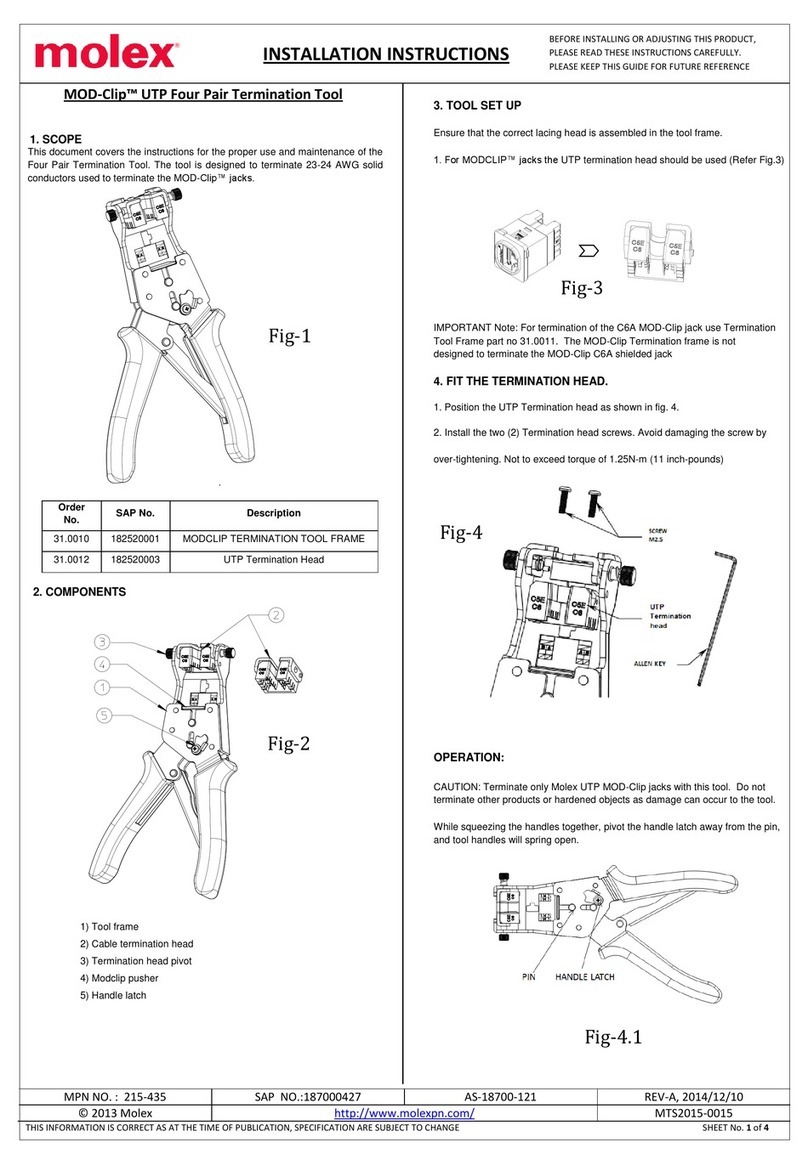

RHT-5770 Hand Crimp Tool

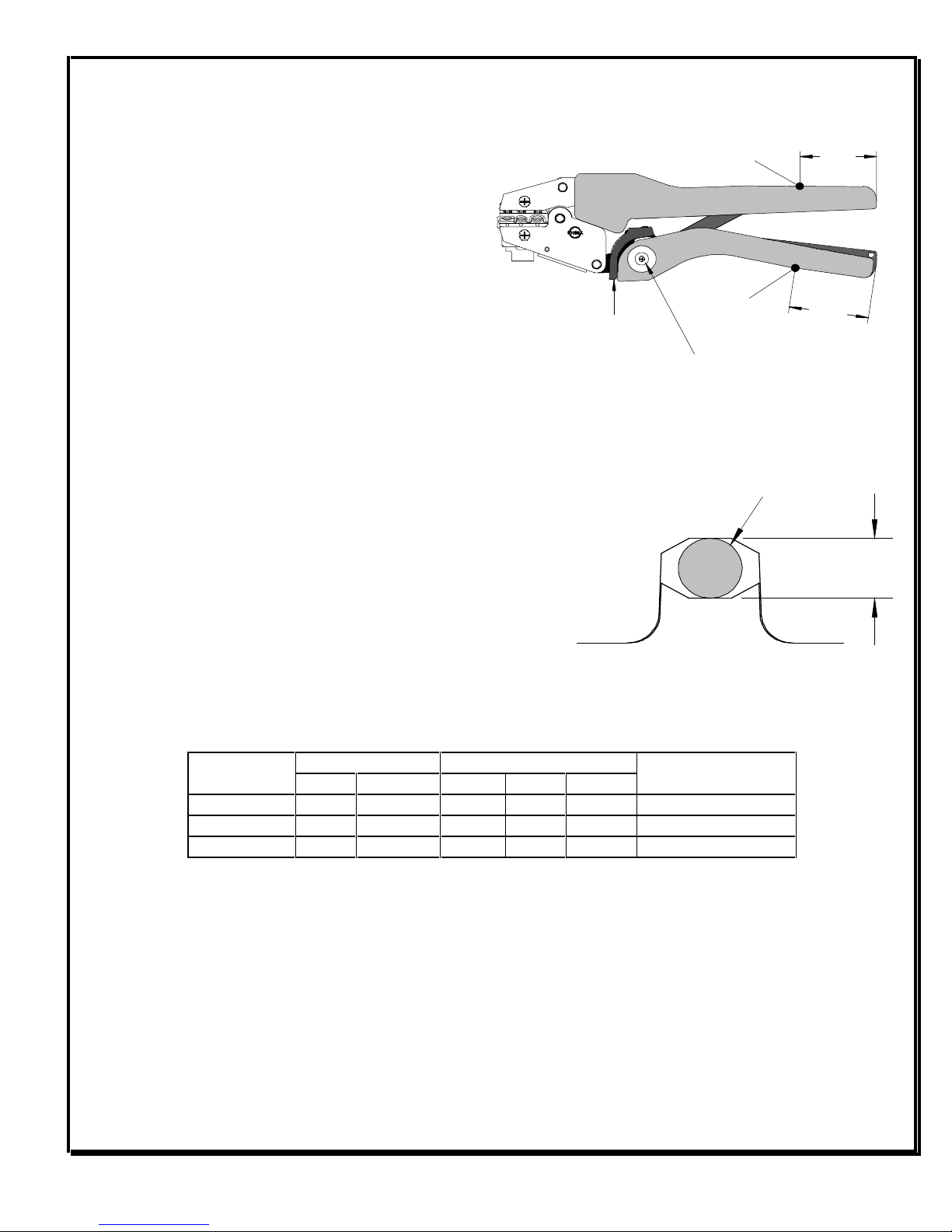

Doc No. 64001-3200 Release Date: 11-11-03 UNCONTROLLED COPY Page 1 of 8

Revision: B Revision Date: 05-24-04

Hand Crimp Tool

Operating Instruction and Specifications Sheet

Part No. 64001-3200

Eng. No. RHT 5770

(Replaces 19285-0050 and 19285-0143)

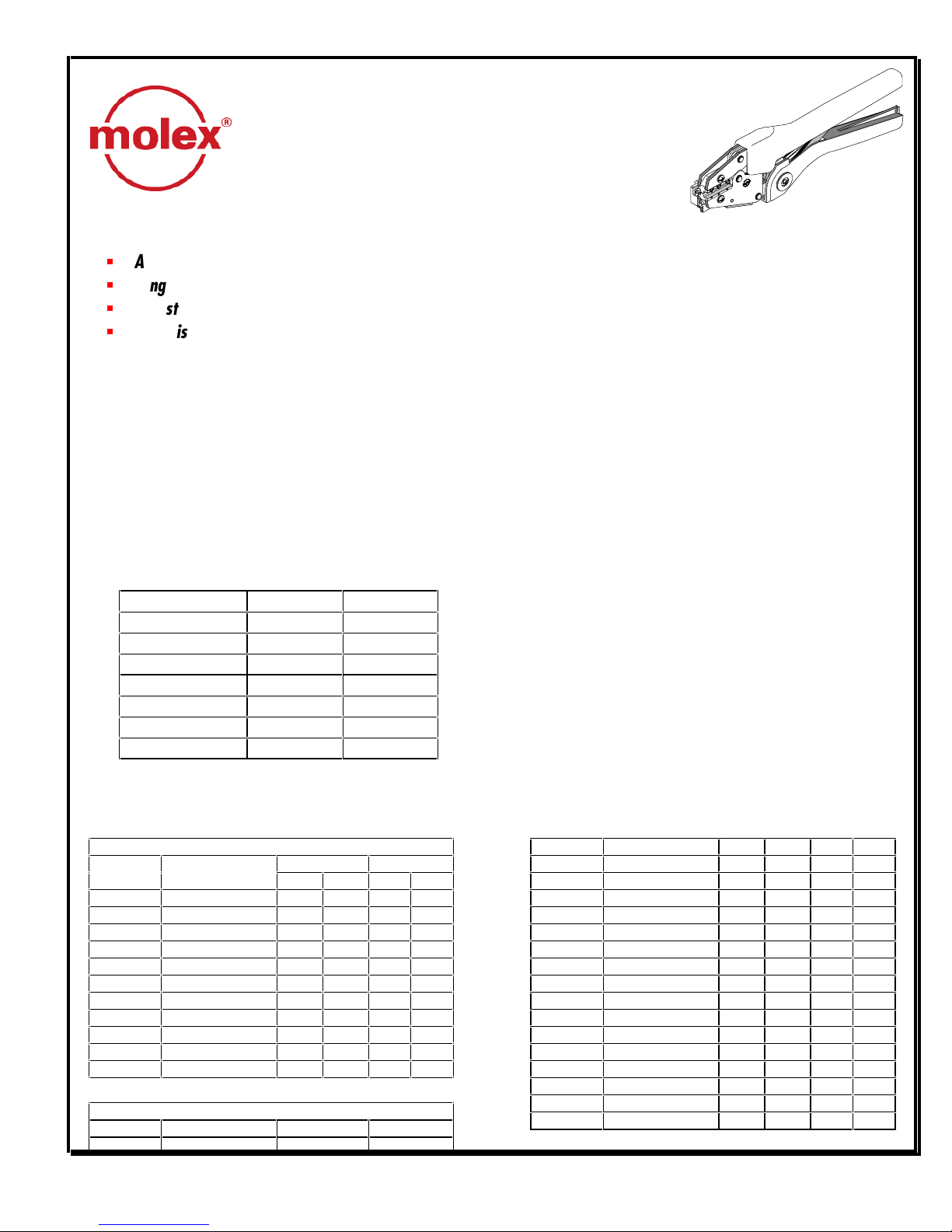

FEATURES

A full cycle ratcheting hand tool ensures complete crimps

Long handles for comfortable crimping with reduced crimping force

3-nested tool eliminates the need for additional tools

A precision user-friendly terminal locator / wire stop holds terminals in the proper crimping position for each of

the three nests

SCOPE

Perma-SealTerminals and Splices 10–22 AWG (Rings, Spades, Hooks, 3 and 4-Ways, and Splices).

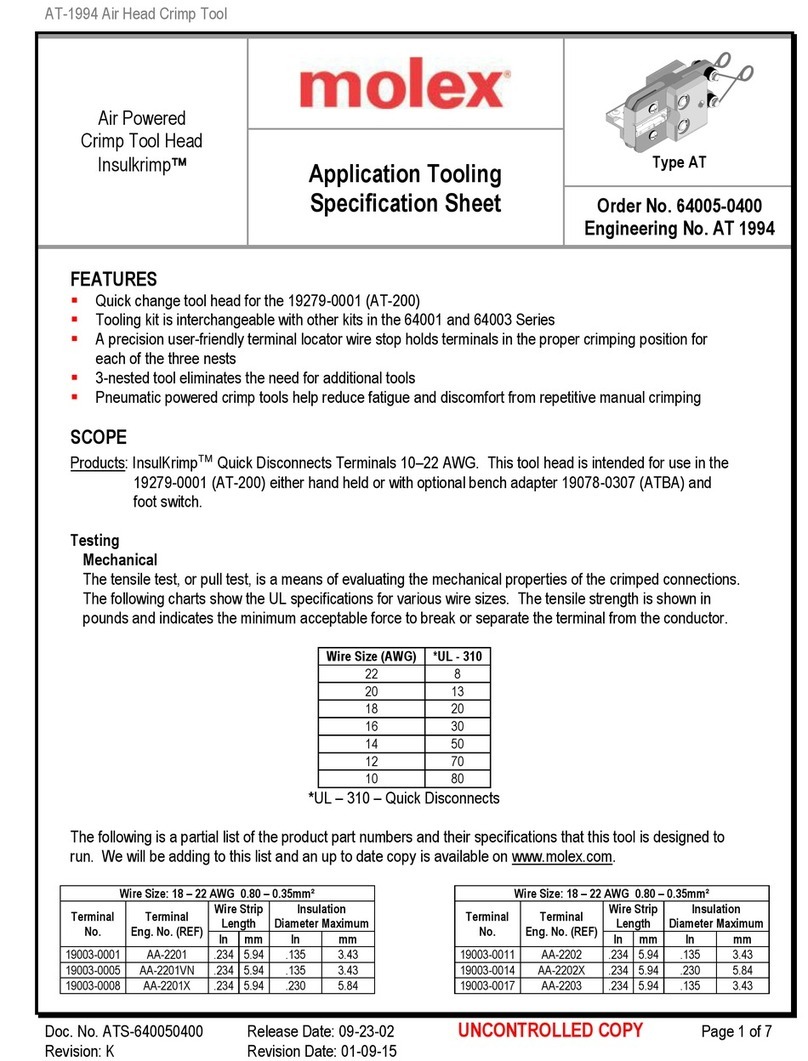

Testing

Mechanical

The tensile test, or pull test, is a means of evaluating the mechanical properties of the crimped connections. The

following charts show the specifications for various wire sizes. The tensile strength is shown in pounds and

indicates the minimum acceptable force to break or separate terminal from the conductor.

*UL - 486 A - Terminals (copper conductors only)

*UL - 486 C - Butt Splices, Parallel Splices

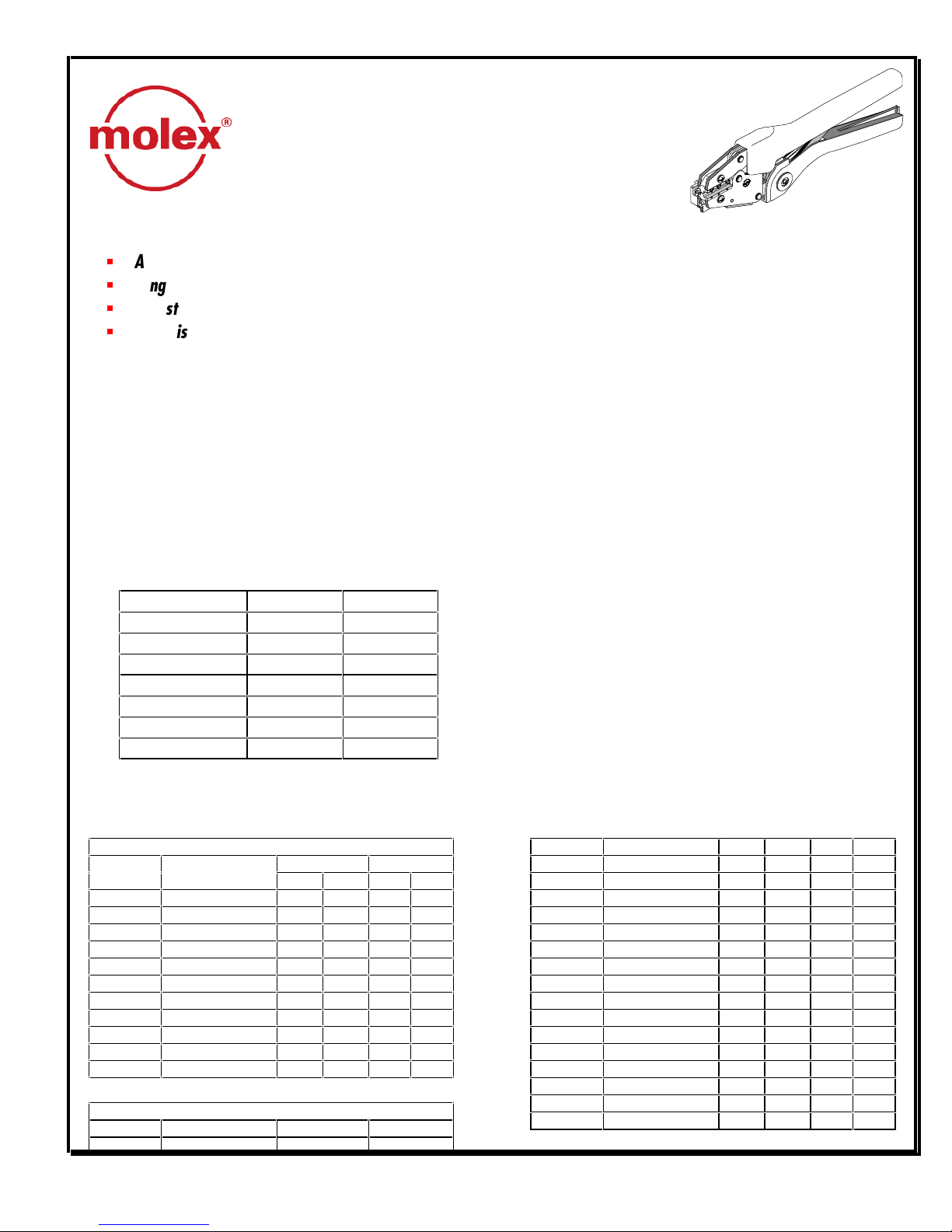

The following is a partial list of the product part numbers and their specifications that this tool is designed to

run. We will be adding to this list and an up to date copy is available on www.molex.com

Wire Size: 18 – 22 AWG 0.80 –0.35 mm²

Wire Strip Length Insul. Dia. Max.

Terminal No. Terminal Eng No. (REF) In. mm In. mm

19040-0001 19040-0001 .300 7.60 .190 4.83

19164-0003 SA-221-10 .281 7.14 .215 5.46

19164-0004 SA-222-14 .281 7.14 .215 5.46

19164-0005 SA-226-38 .281 7.14 .215 5.46

19164-0006 SA-235-06 .281 7.14 .215 5.46

19164-0007 SA-235-08 .281 7.14 .215 5.46

19164-0008 SA-235-10 .281 7.14 .215 5.46

19164-0011 SA-2YCX .281 7.14 .215 5.46

19164-0013 SAA-22-18 .281 7.14 .210 5.33

19164-0085 SA-221-06 .281 7.14 .215 5.46

19164-0086 SA-221-08 .281 7.14 .215 5.46

Wire Size: 14 –16 AWG 2.00 –1.30 mm²

Terminal No. Terminal Eng No. (REF) Wire Strip Length Insul. Dia. Max.

In. mm In. mm

19040-0002 19040-0002 .300 7.60 .200 5.08

19164-0020 SB-218-38 .281 7.14 .235 5.97

19164-0021 SB-219-10 .281 7.14 .235 5.97

19164-0026 SB-225-14 .281 7.14 .235 5.97

19164-0027 SB-225-56 .281 7.14 .235 5.97

19164-0028 SB-227-06 .281 7.14 .235 5.97

19164-0029 SB-227-08 .281 7.14 .235 5.97

19164-0030 SB-227-10 .281 7.14 .235 5.97

19164-0031 SB-237-04 .281 7.14 .235 5.97

19164-0032 SB-237-06 .281 7.14 .235 5.97

19164-0033 SB-237-08 .281 7.14 .235 5.97

19164-0034 SB-237-10 .281 7.14 .235 5.97

19164-0042 SB-2YCX .281 7.14 .235 5.97

19164-0044 SBB-16-14 .375 9.53 .200 5.08

19164-0141 SB-219-06 .281 7.14 .235 5.97

19164-0142 SB-219-08 .281 7.14 .235 5.97

Wire Size (AWG) UL –486 A UL –486 C

22 8 8

20 13 10

18 20 10

16 30 15

14 50 25

12 70 35

10 80 40