Table of Contents

<Safety Precautions> Page

1. Introduction ...................................................................................................A-1

2. To operation supervisors.............................................................................A-1

3. Dangerous operations..................................................................................A-1

4. Careful handling............................................................................................A-2

5. Installation site..............................................................................................A-2

<Quality Precautions>

1. Introduction ...................................................................................................B-1

2. Must be carried out.......................................................................................B-1

3. Must not be carried out ................................................................................B-1

1. Description 1

2. Machine Configuration and Applicable Products

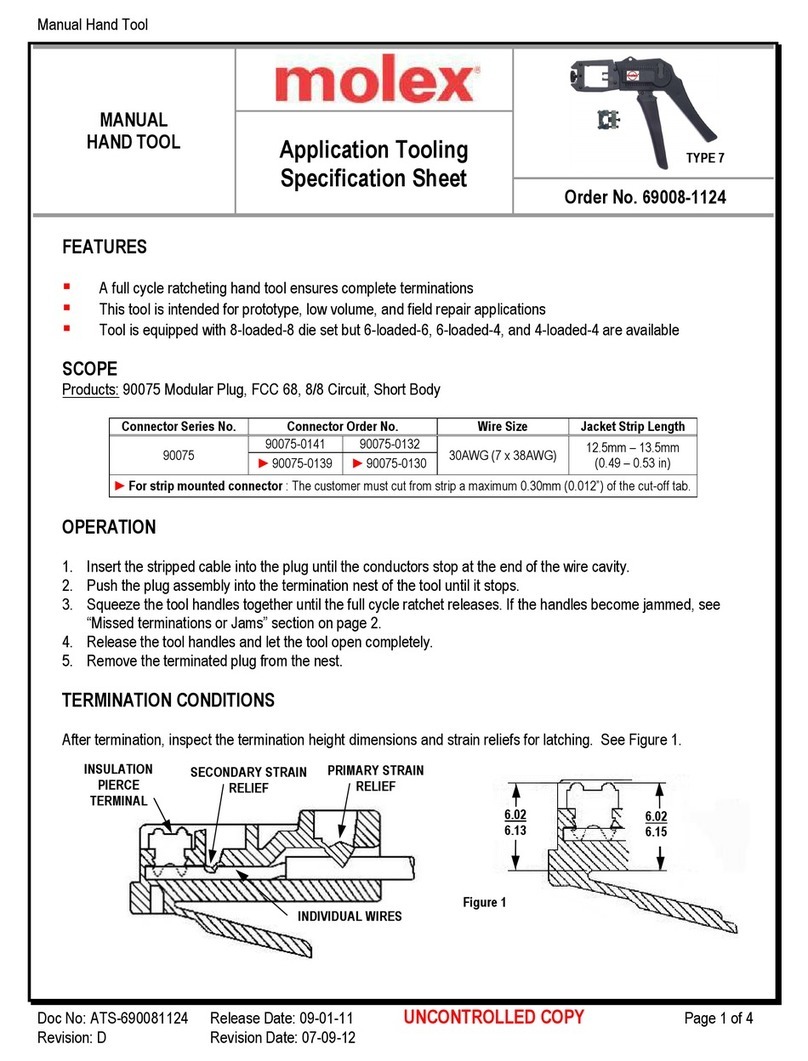

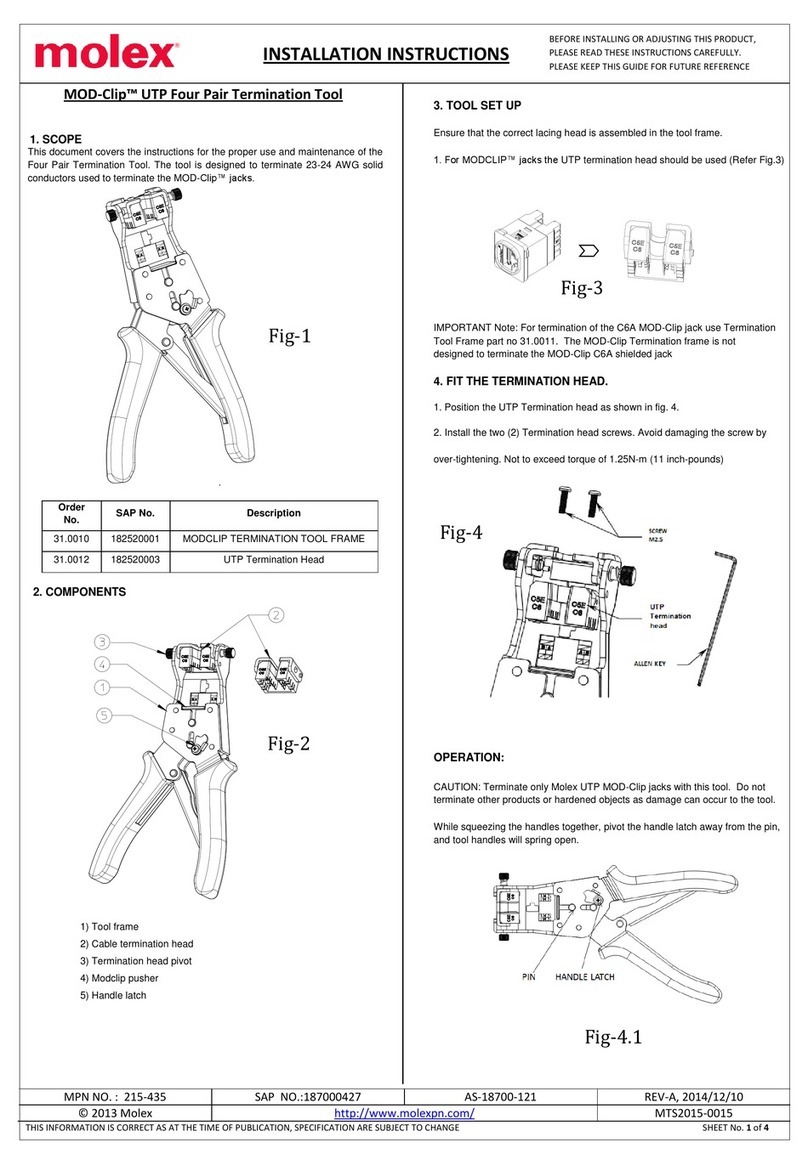

2.1. Machine Name and Configuration................................................................................... 1

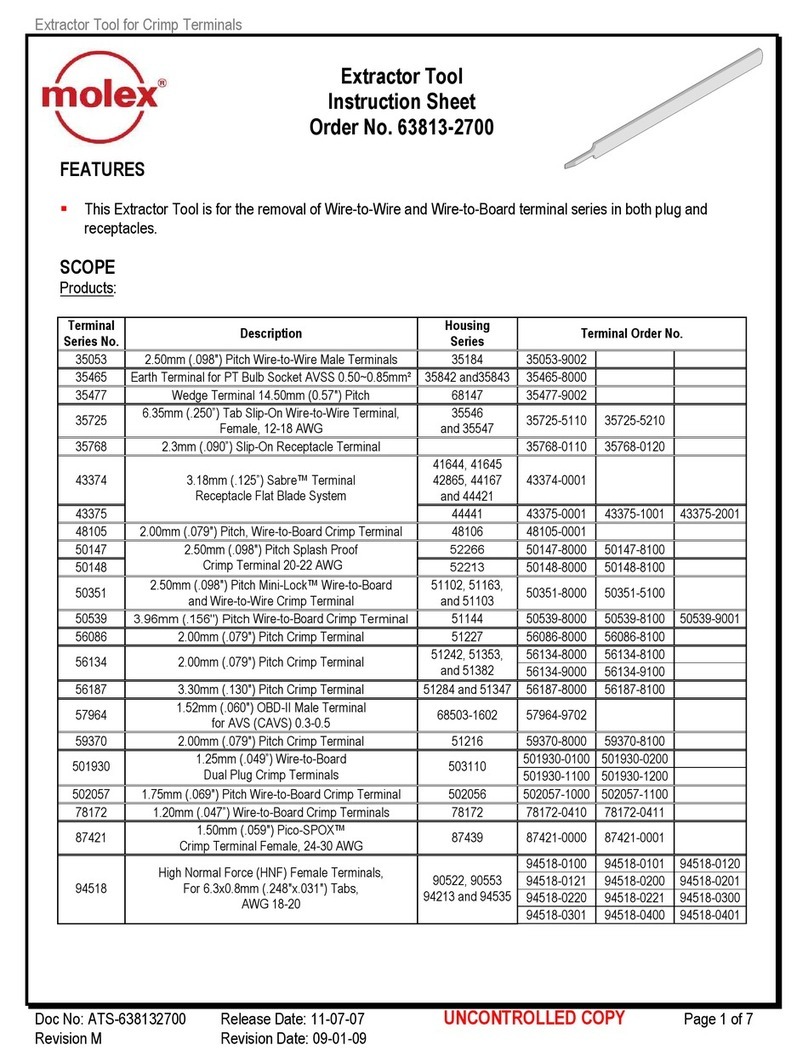

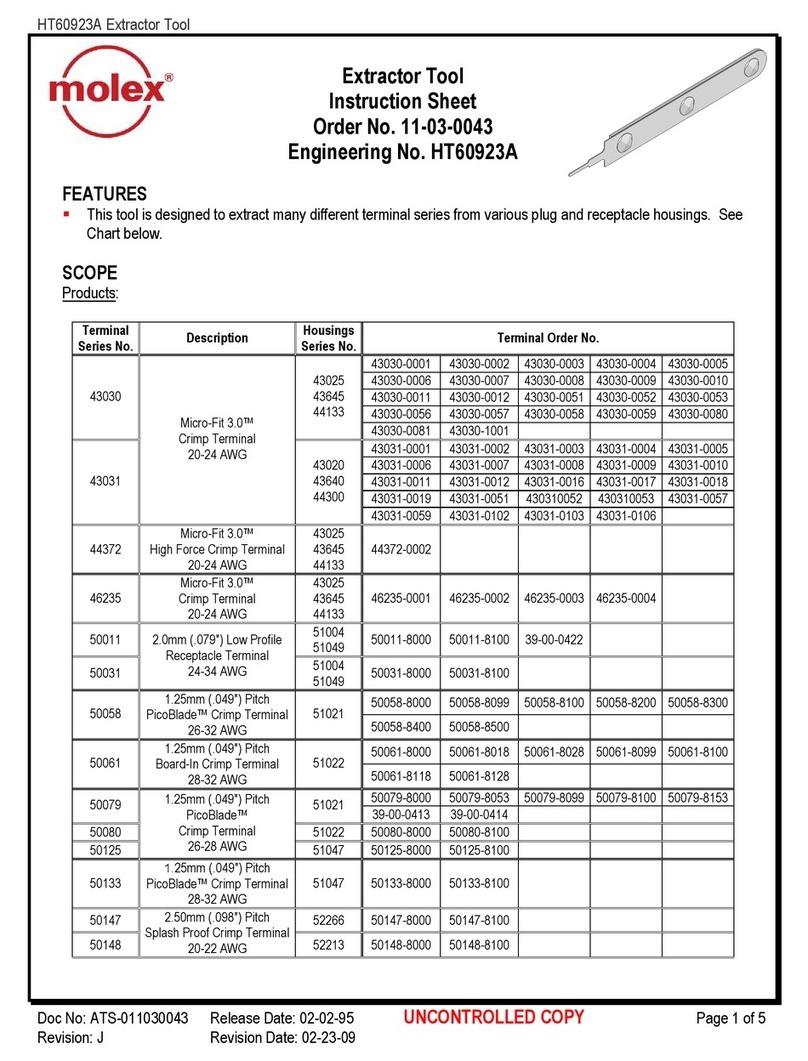

2.2.Applicable Connector and Wire....................................................................................... 1

2.3. Machine Appearance and Unit Name.............................................................................. 2

3. Specifications

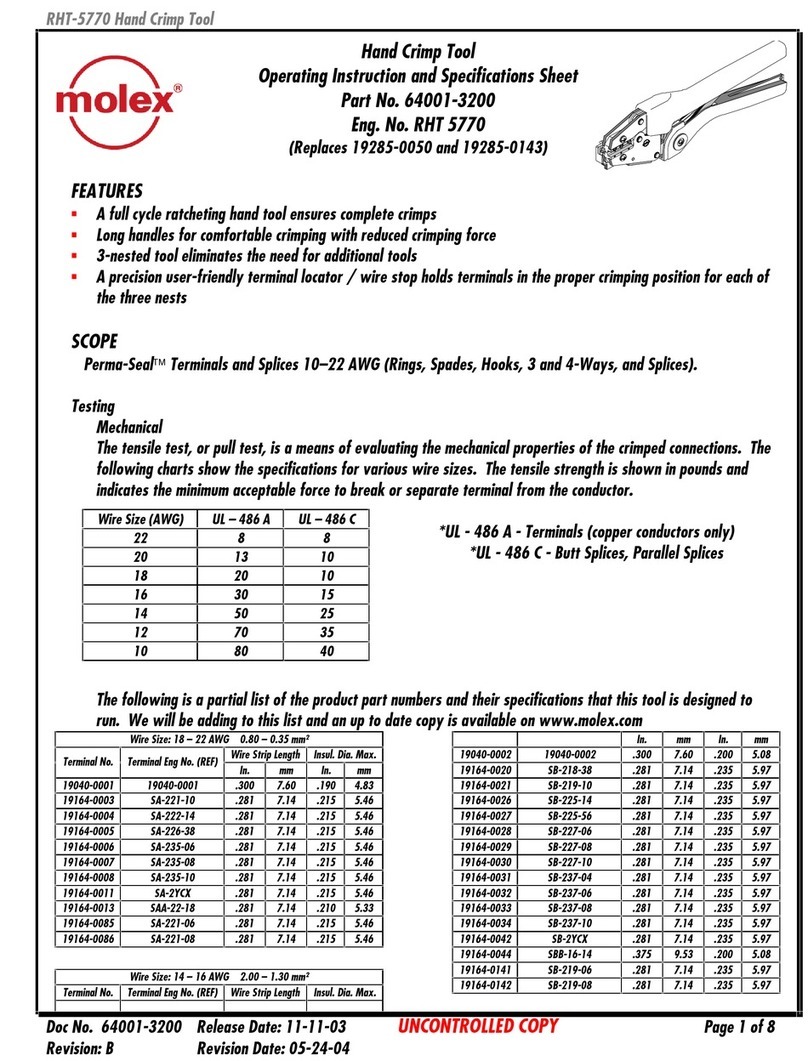

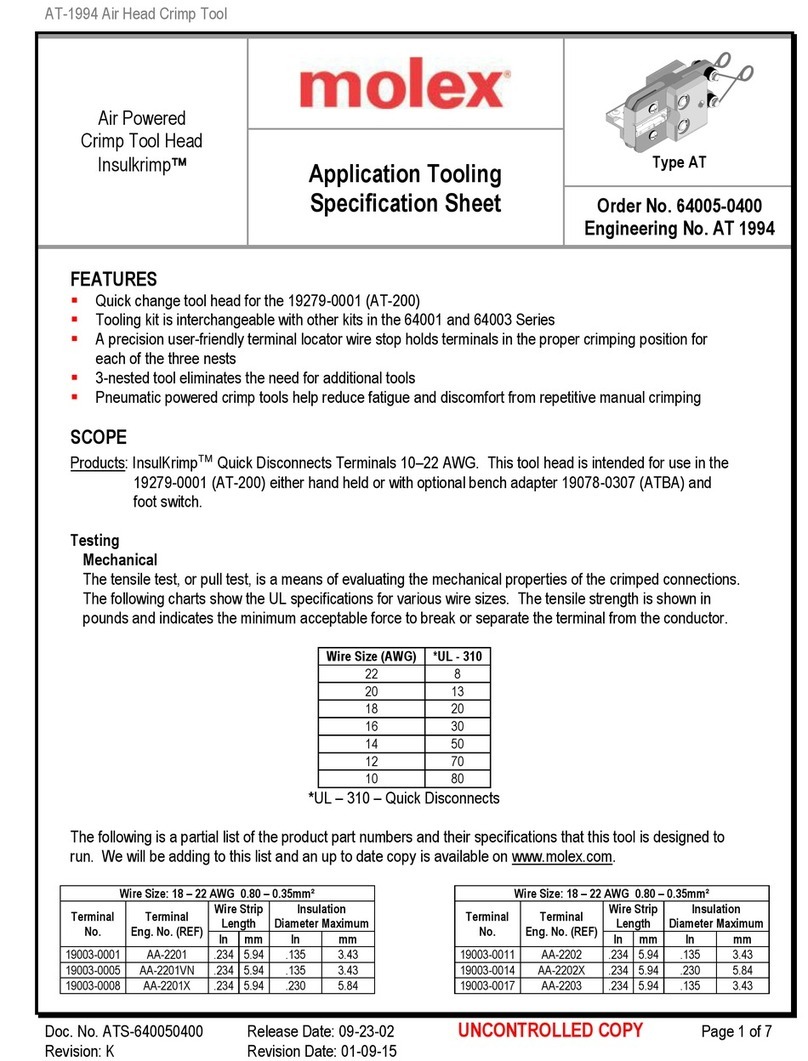

3.1. Machine Specifications.................................................................................................... 3

3.2. Power Source Specifications........................................................................................... 3

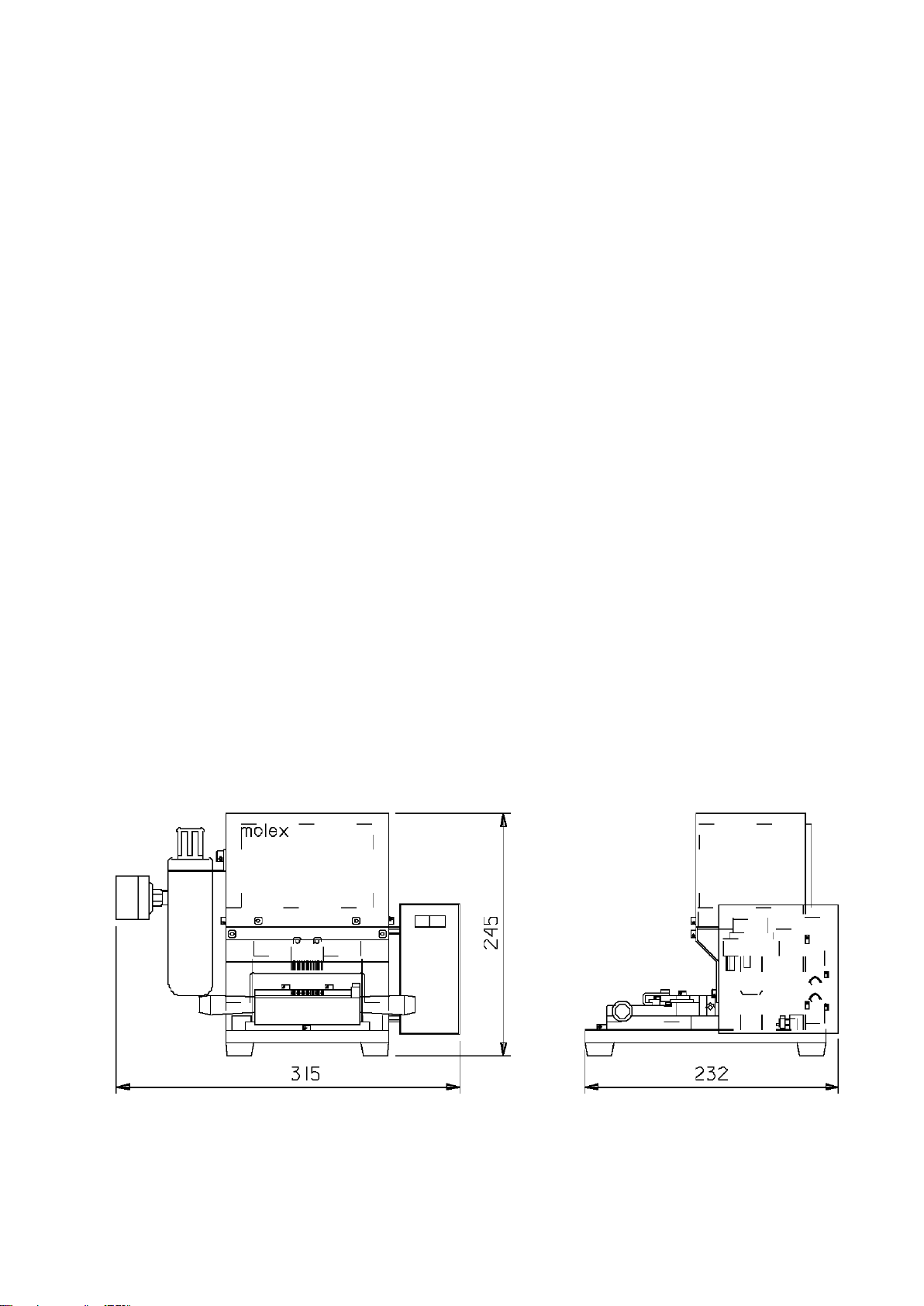

3.3. External Size and Weight ................................................................................................ 3

3.4. Operating Environment Conditions ................................................................................. 4

3.5. Installation Space............................................................................................................. 4

4. Installation of Machine

4.1. Installation........................................................................................................................ 5

4.2. Operation Preparation ..................................................................................................... 5

5. Operation Method

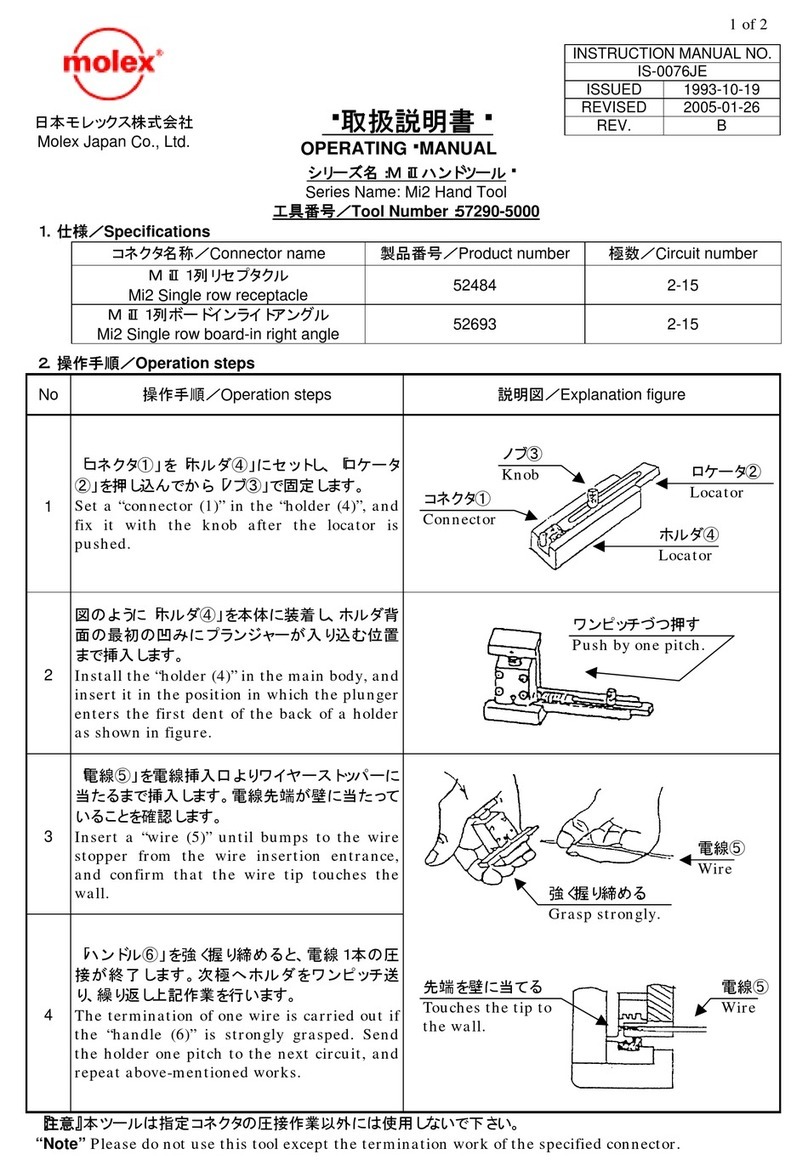

5.1. Termination Procedure..................................................................................................... 6

5.2. Set of Connector.............................................................................................................. 7

5.3. Wire Arrangement and Termination................................................................................. 8

6. Maintenance and Check

6.1. Daily Maintenance........................................................................................................... 9

6.2. Checking of Machine..................................................................................................... 10

6.3.Adjusting Method of Termination Depth..........................................................................11

6.4.Adjusting Method of Connector Position ....................................................................... 12

7. Cause and Measures of Breakdown...................................................................................... 13

8. Block Diagram14

9. Parts List

9.1. Termination Unit............................................................................................................. 15

9.2. Press Unit ...................................................................................................................... 17

10. Startup Checklist..................................................................................................................... 19