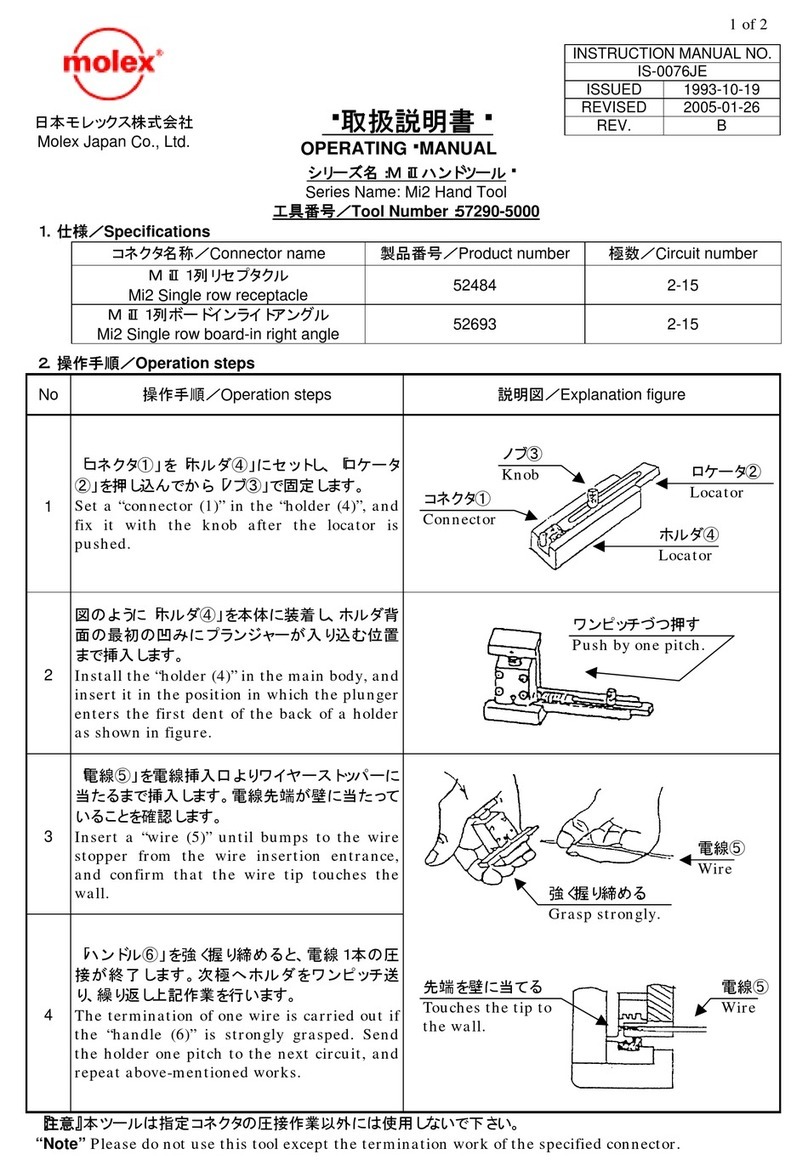

A–1

<Safety Precautions>

Please read the following before operating the tool.

Thank you for choosing our Splash Proof Connector Cap Fitting Tool.

This document is prepared so that the tool is properly used.

Please take the time to read this manual, making sure you understand the operating

procedures described herein before attempting to operate the tool.

1) Don’t insert a part of your body or other foreign materials in the splash proof connector cap fitting

tool (hereinafter referred to as the “tool”) while you’re operating the handle of a tool, as injury my

result.

2) Beware of a handle when it is opened. Releasing a ratchet may cause the handle to open

abruptly, resulting in injury.

3) Only users who have received adequate training on usage and safety from their manager, and

have appropriate knowledge and skills must use the tool. Use by unfamiliar users may cause

injury.

<Caution>

1) Unauthorized reproduction of this document in part or in whole is prohibited.

2) The contents of this document are subject to change without notice.

3) Molex Japan Co., Ltd. assumes no responsibility for losses resulting from use or misuse

of this document.