Table of Contents

<Safety Precautions> Page

1. Introduction.................................................................................................A-1

2. To operation supervisors .............................................................................A-1

3. Dangerous operations..................................................................................A-1

4. Careful handling..........................................................................................A-2

5. Installation site ...........................................................................................A-2

<Quality Precautions>

1. Introduction.................................................................................................B-1

2. Must be carried out .....................................................................................B-1

3. Must not be carried out...............................................................................B-1

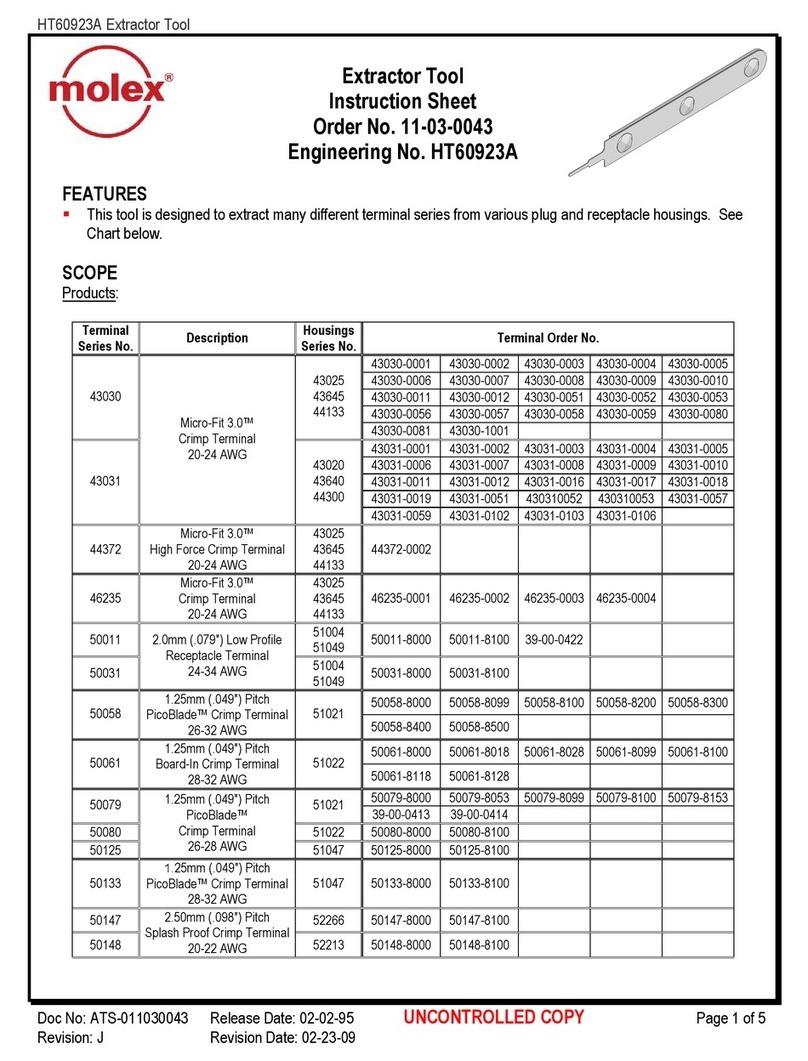

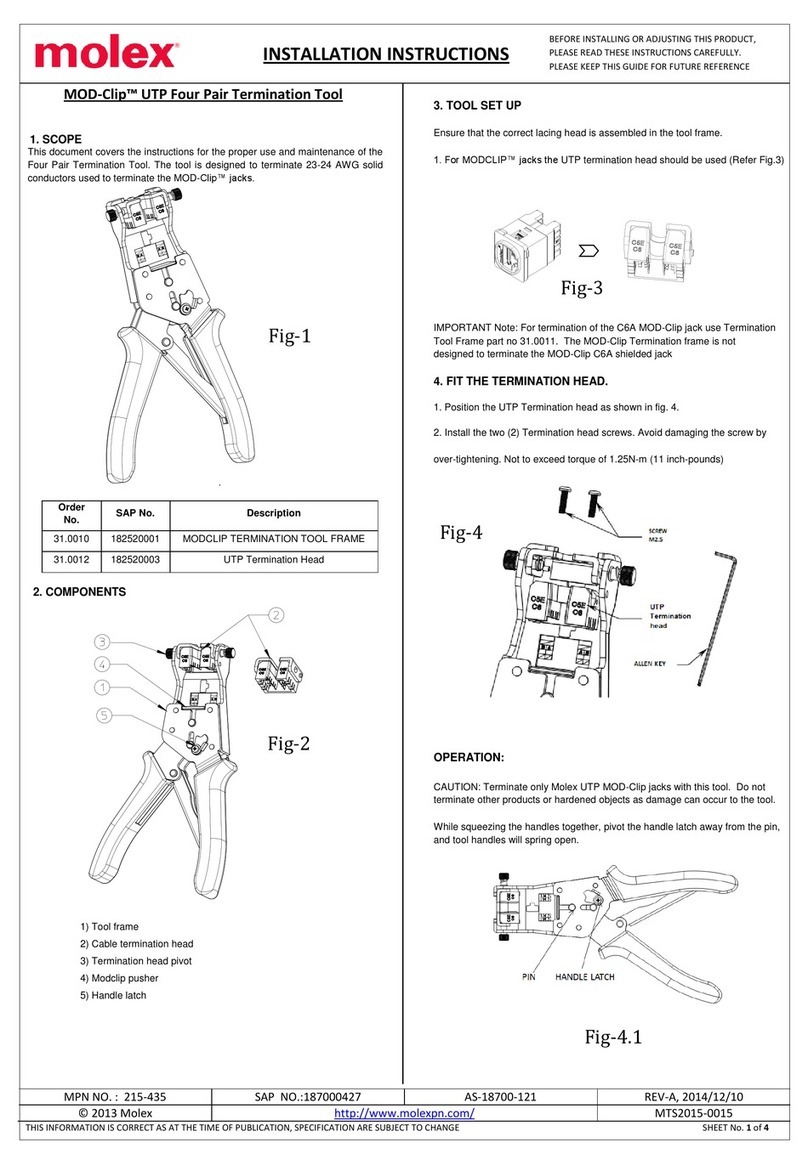

1. Description ........................................................................................................................1

2. Tool Configuration and Applicable Products

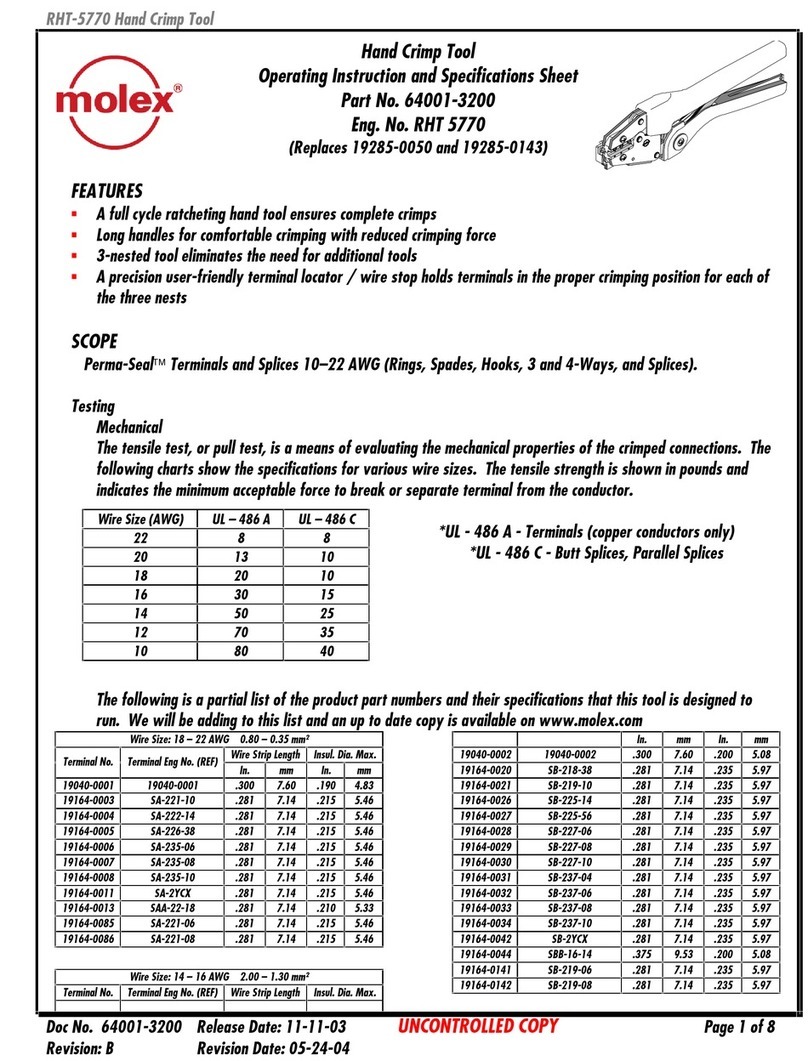

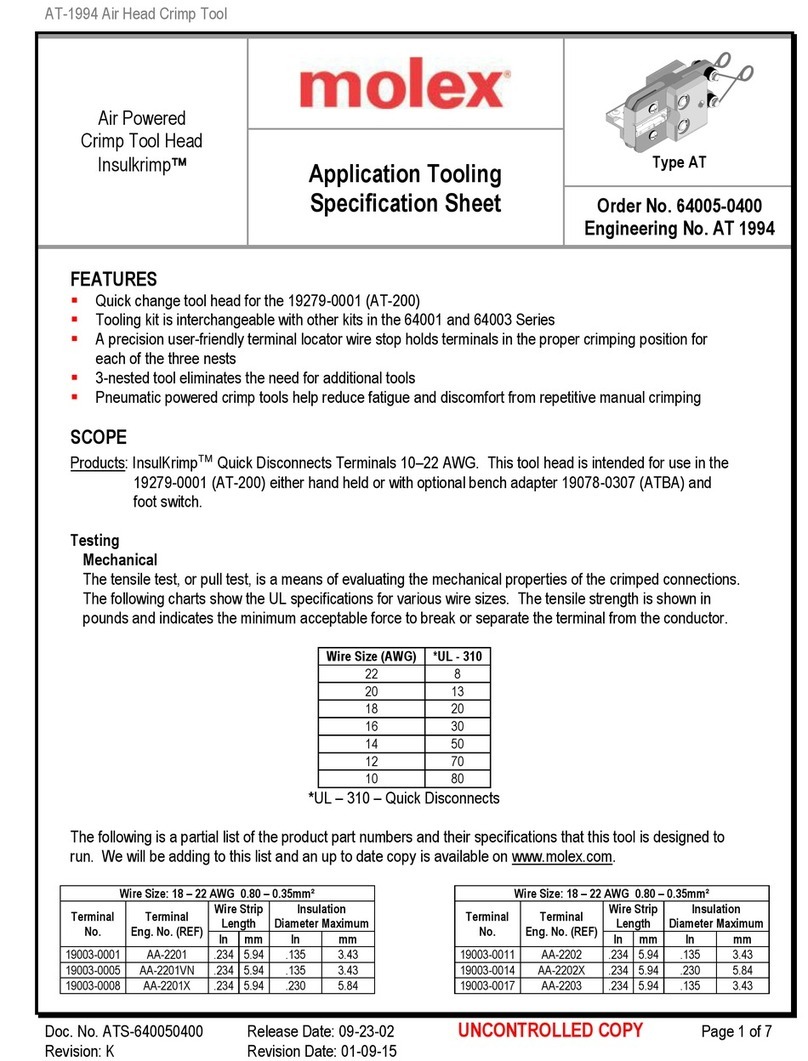

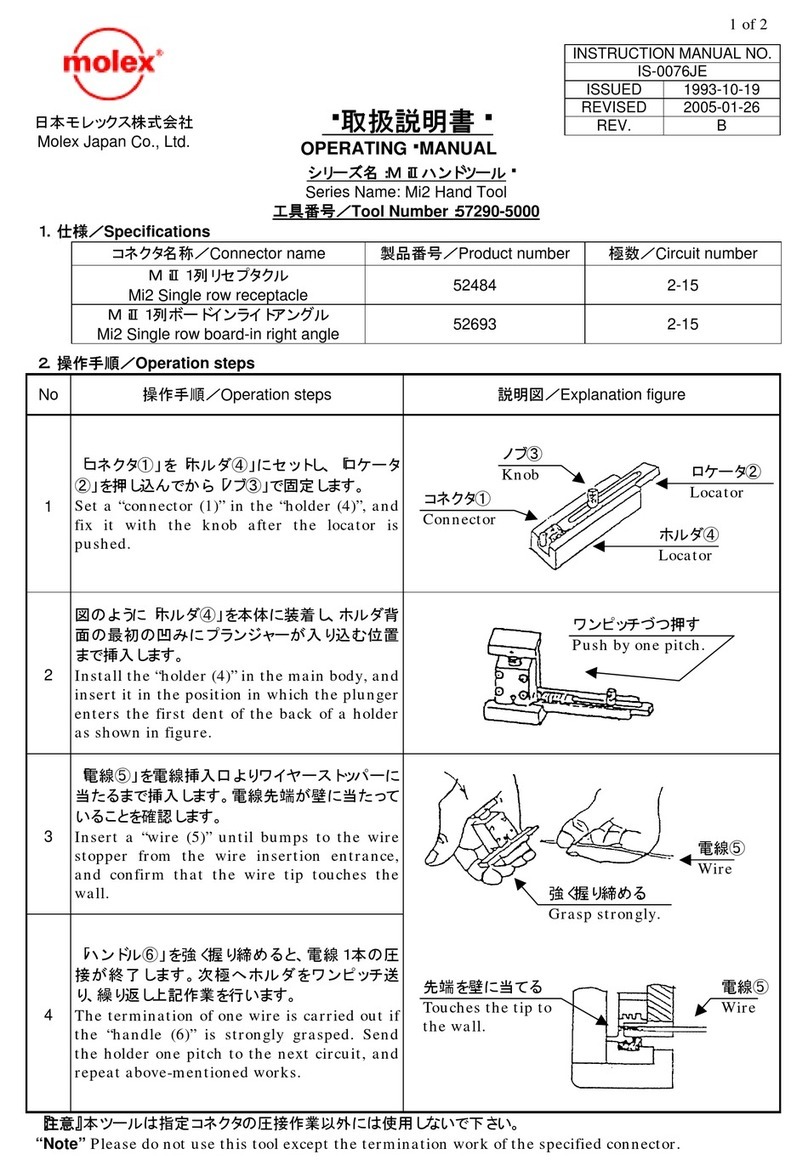

2.1. Tool Name and Configuration....................................................................................1

2.2. Applicable Connector and Cable................................................................................1

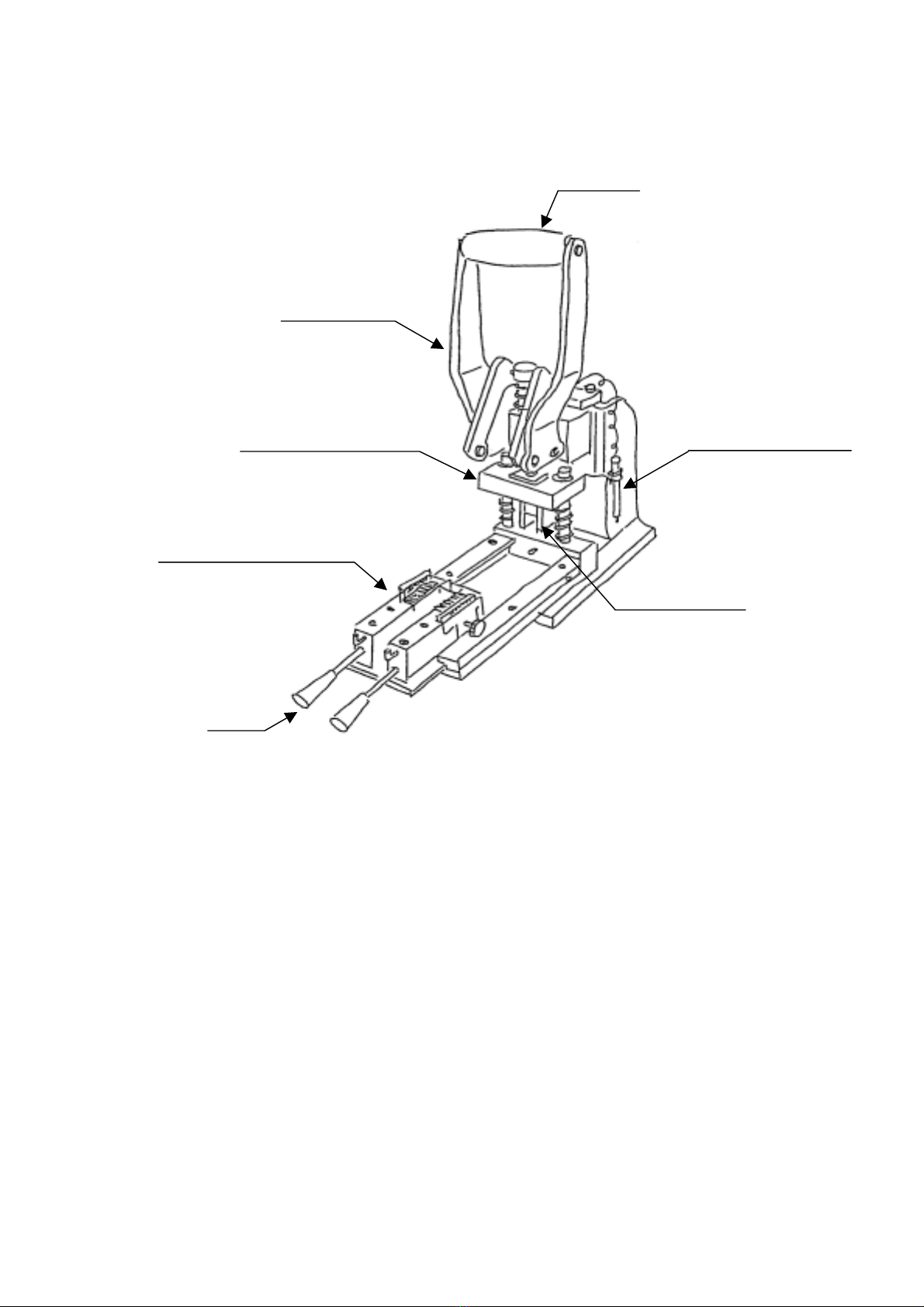

2.3. Tool Appearance and Unit Name...............................................................................2

3. Specifications

3.1. Tool Specifications......................................................................................................3

3.2. Outer Dimensions and Weight...................................................................................3

3.3. Operating Environment Conditions..........................................................................4

3.4. Installation Space.......................................................................................................4

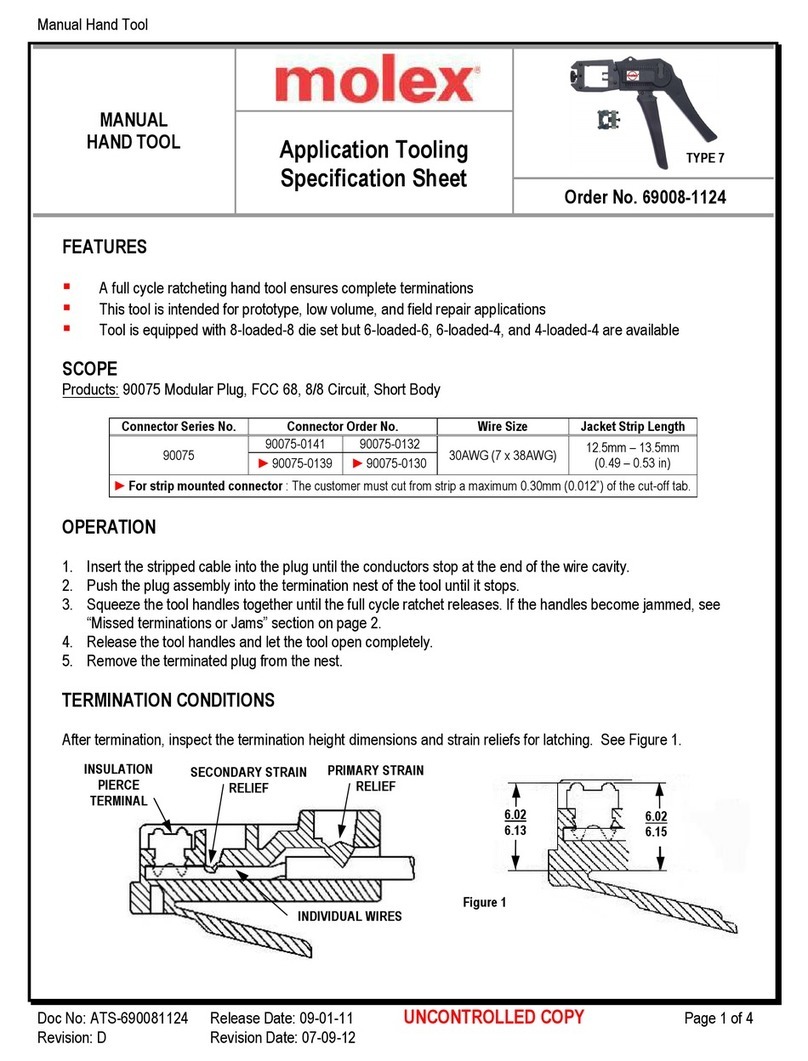

4. Operation Method

4.1. Setting of Upper Cover...............................................................................................5

4.2. Setting of Cable..........................................................................................................6

4.3. Wire Arrangement......................................................................................................7

4.4. Wire Pushing and Cutting.........................................................................................8

5. Maintenance and Check

5.1. Daily Maintenance.....................................................................................................9

5.2. Check of Tool.............................................................................................................10

5.3. Exchange method of Wire Cut Blade and Wire Pusher..........................................11

5.4. Adjustment Method of Wire Pusher Bottom Dead Point .......................................12

5.5. Adjustment Method of Hand Press Bottom Dead Point.........................................13

6. Parts List

6.1. Wire Arrangement Unit Development ....................................................................14

6.2. Wire Pushing Unit Development.............................................................................15

6.2. Parts List..................................................................................................................16

7. Startup Checklist ...............................................................................................................18