Manual Press for SC Power

Order No: TM-640000041 Release Date: 05-02-13 UNCONTROLLED COPY Pa e 9 of 16

Revision: C Revision Date: 05-02-13

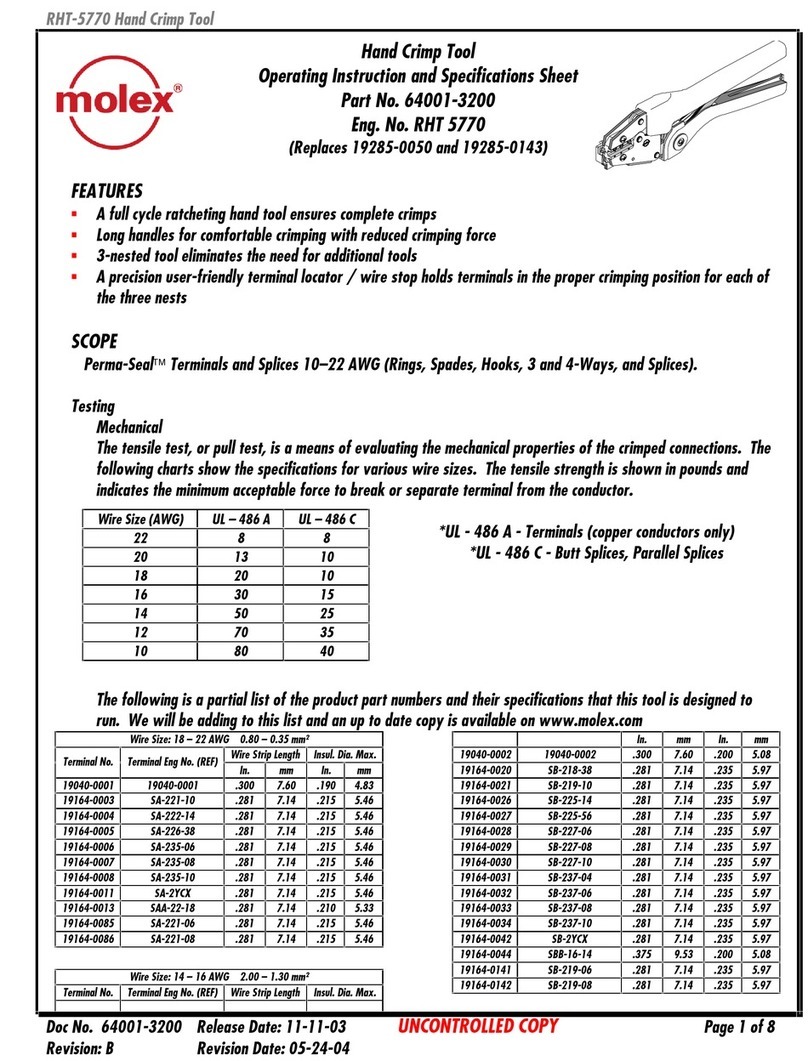

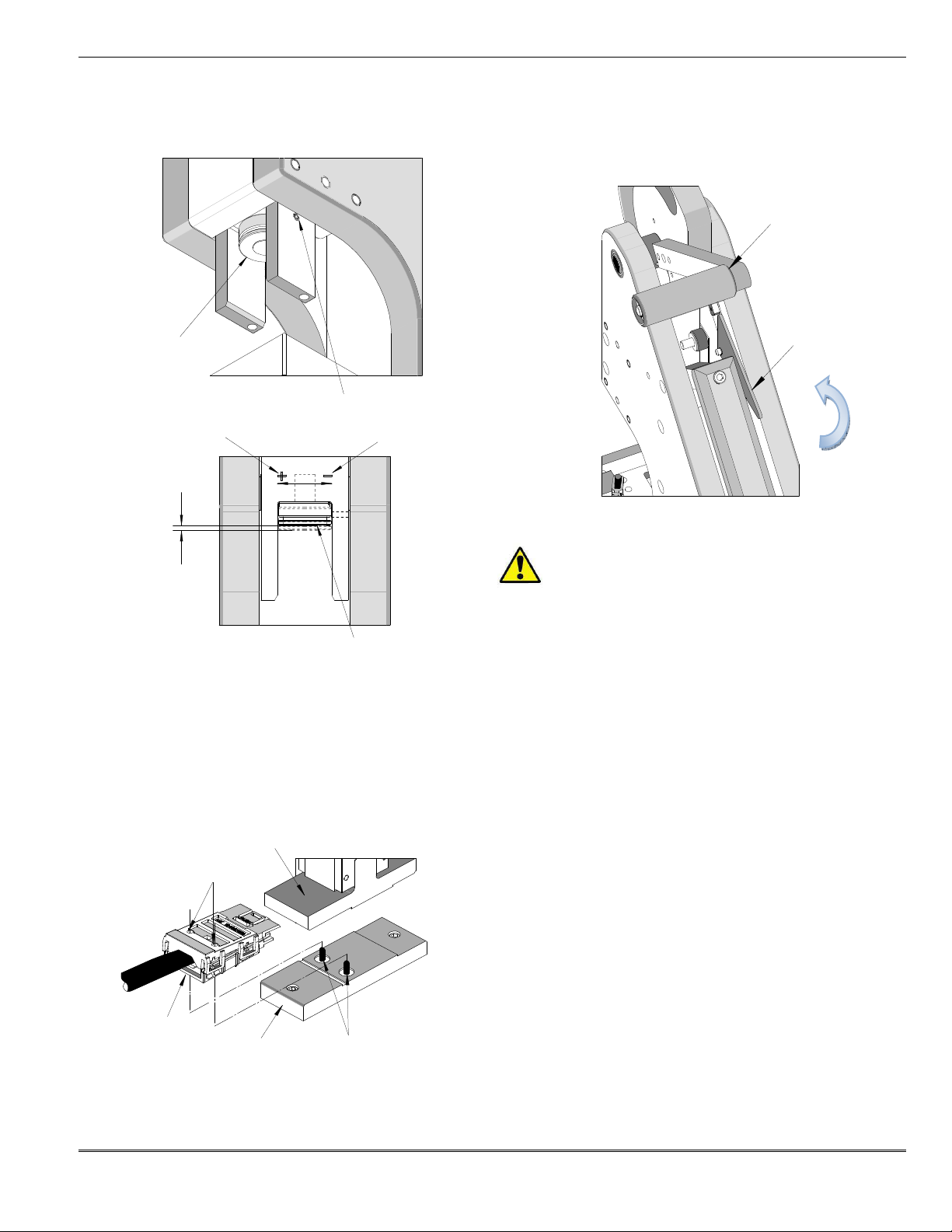

LOADED SCREW (2)

TOOLING

BASE PLATE

#8-32 BHCS (2)

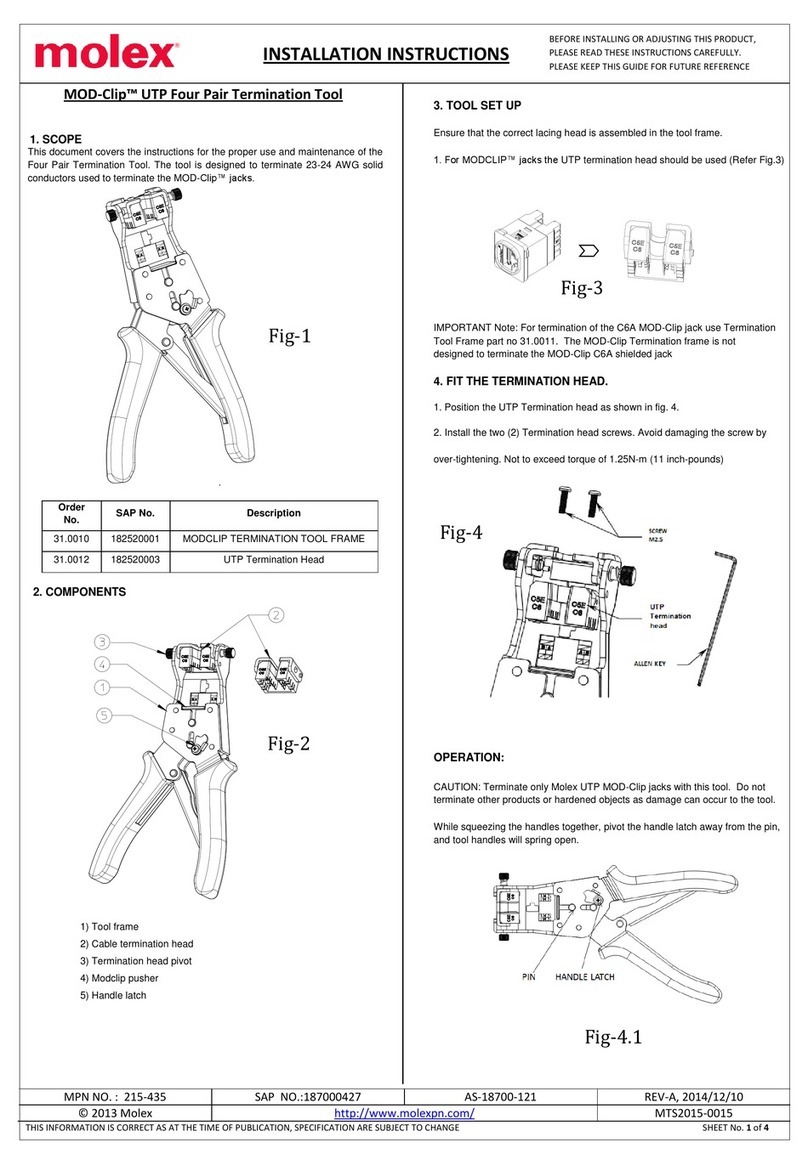

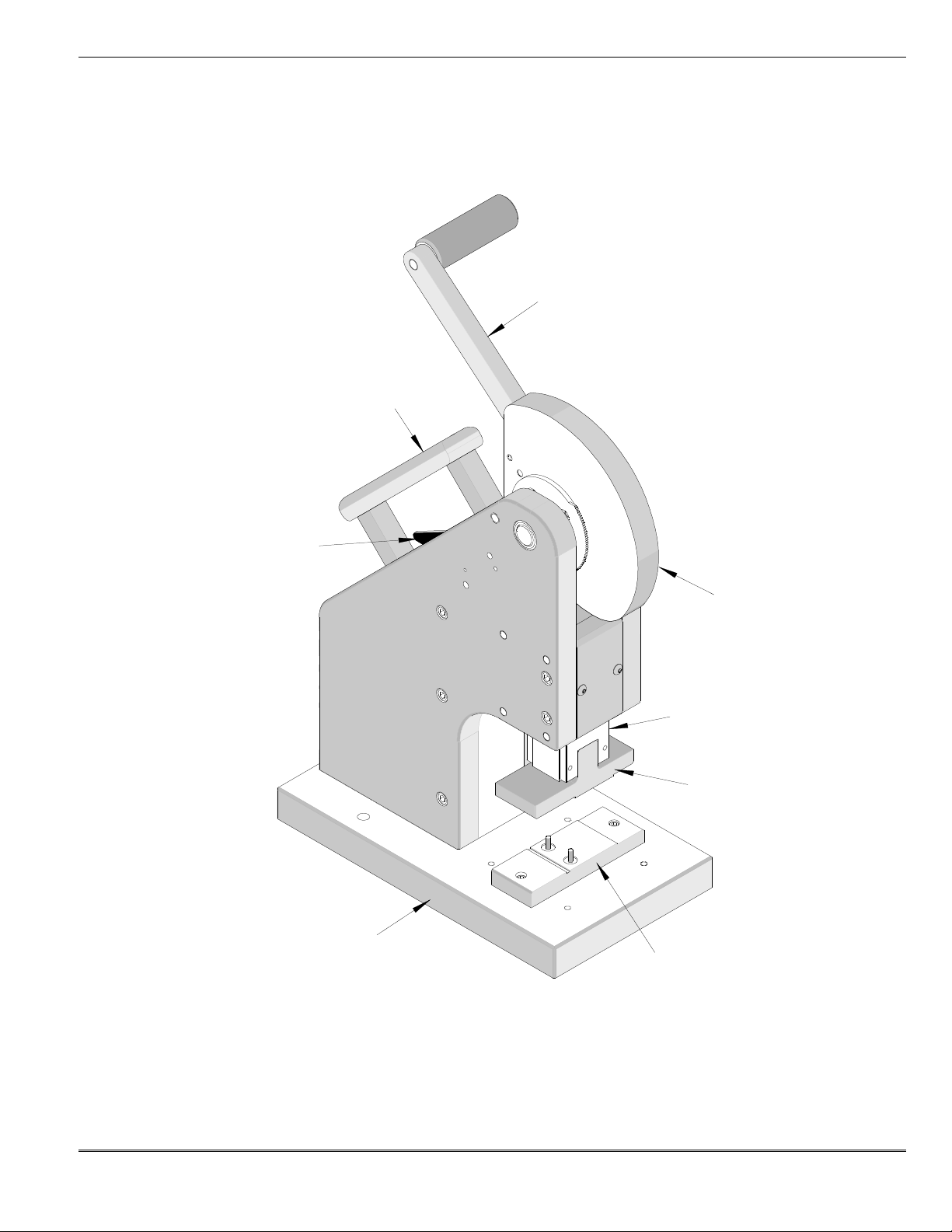

Figure 2-2

TOOLING

ADJUSTING

SCREW

TOOLING

HOLDER

Operation

2 1 Installation

To secure the press, use a bench capable of

supportin at least 150 pounds (70k ), with

adequate li htin for easy operation. There are two

(2) holes for 5/16” la screws provided in the press

base for fastenin the press to the workbench. Be

sure there is adequate room around the press to

operate easily.

The 64000-0041 Complete Manual Press comes

with tool kit already installed. See Fi ure 2-1. If the

64000-0045 Tool Kit is not installed in the Press,

follow the steps below:

Upper Tooling

NOTE: Lowerin the press ram sli htly may assist

in installin the upper toolin .

1. Slide the upper toolin holder with upper toolin ,

upward over the ram adjustin screw, until it

comes to a stop. See Fi ure 2-2.

2. Push the latch backward (away from the

operator). The upper toolin will now slide up

onto the ram an additional approximately 4.0mm

(0.16”).

3. Release the latch, the upper toolin will stay in

place.

Lower Tooling

1. Remove the two (2) sprin loaded screws with

the washers and sprin s on the base plate of

the Basic Press.

2. With the press ram in the up position, position

the lower toolin in the press.

3. Slide the lower toolin onto the base plate.

Fasten down with the (2) #8-32 BHCS

(Furnished with the tool kit). See Fi ure 2-3.

4. Slowly lower the press ram by pullin the press

lever forward and down.

5. Return the press ram to the full up position.

2 2 Set Up

The only setup required for this toolin is to adjust

the press ram stroke.

Ram Stroke Adjustment

1. Loosen the #8-32 set screw in the Ram which

locks the Ram Adjustin Screw into place. See

Fi ure 2-4.

2. There is an indicator en raved on the ram just

above the Ram Adjustin Screw. Turn the Ram

Adjustin Screw clockwise (CW) toward the “+”

si n to increase the ram stroke. To decrease

the stroke, turn the Ram Adjustin Screw

counterclockwise (CCW) toward the “-” si n.

Stroke adjustment controls the shut hei ht of the

connector assembly. Ram stroke is set so that

the connector measures a specific shut hei ht

when terminated. See Product Specifications