1

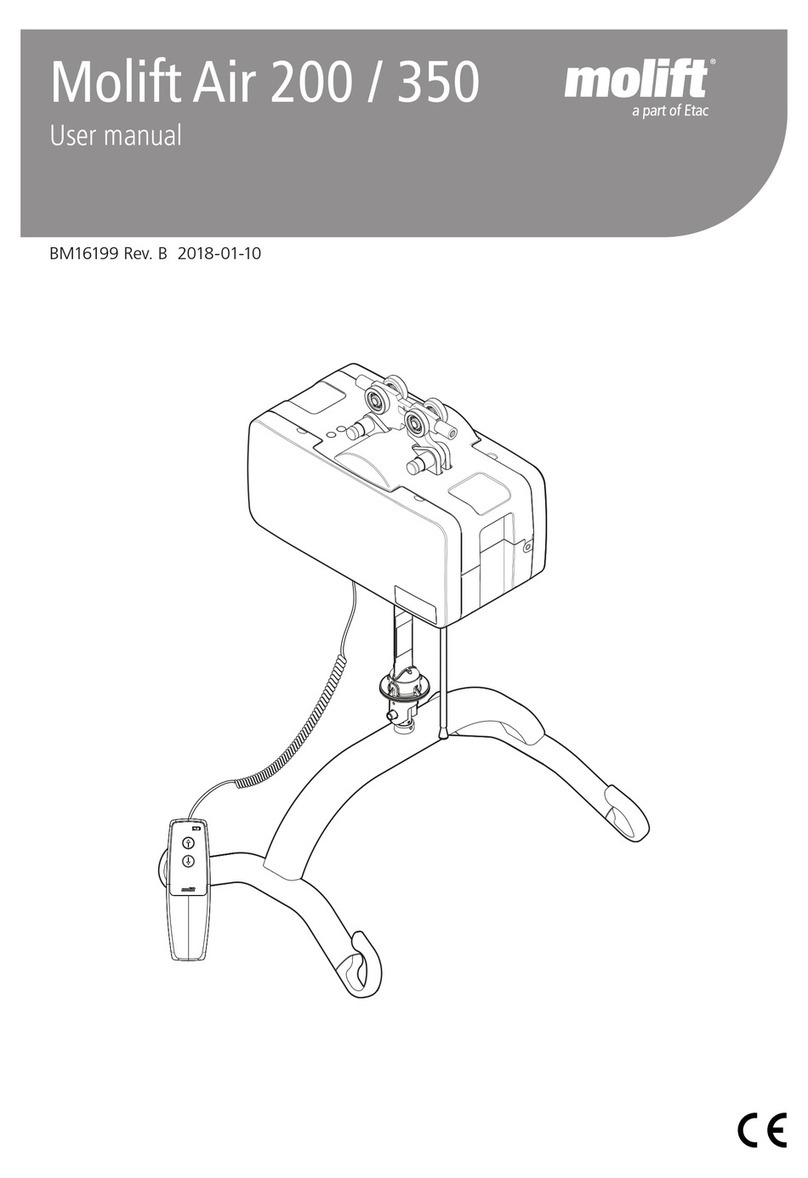

Molift Air / www.molift.com

Content

General.....................................................2

How to open.............................................3

Disconnect battery ....................................3

Molift Service Tool.....................................4

Technical description .................................5

Measurements ..........................................6

Air Components........................................7

Spare part list..........................................12

Labels ..................................................... 13

Battery.................................................... 14

Covers ....................................................15

Hand control ........................................... 17

Angle Sensor/Ens Sensor..........................18

Suspension coupling................................19

Emergency Stop/Lowering .......................20

Replacing Lifting Band .............................21

Brake ......................................................22

Lifting Motor/Gear House ........................23

Microswitches .........................................24

PCB (Printed Circut board) .......................25

Electric Diagram ......................................26

Trolley .....................................................27

IRC (In rail charging) ................................28

Propulsion ...............................................28

Documenting the Service.........................29

Periodic Inspection Checklist Molift Air ....30

Safety checklist after Service and Repair...31

Service Log .............................................32

Installation ..............................................33

Notes ......................................................33

Important

This Technical Manual contains important safety

instructions and information regarding the repair

and service of the lifter and accessories.

Warning!

This symbol indicates important

information related to safety.

Follow these instructions carefully.

Read User Manual before use!

It is important to fully understand

the content of the user manual

before attempting to use the

equipment.

Visit www.molift.com for download of documen-

tation to ensure you have the latest version.

Conditions of Performing Service/Repair

Lift and transfer of a person will always pose

a certain risk and only certified personnel are

allowed to repair and service the equipment and

accessories covered by this technical manual.

Only certified personnel are

allowed to open hoist or acces-

sories to perform service or repair.

Risk of injury from rotating parts

and electric shock.

Activate emergency stop before

opening side covers. Disconnect

battery before any repair or

service.

When disassembling and assem-

bling the lifter, take care that no

cables are squeezed or damaged,

this might cause malfunction.

Any Service or Repair should be

documented in the service log, and

verified by using the Checklist after

service and repair.

English Manual