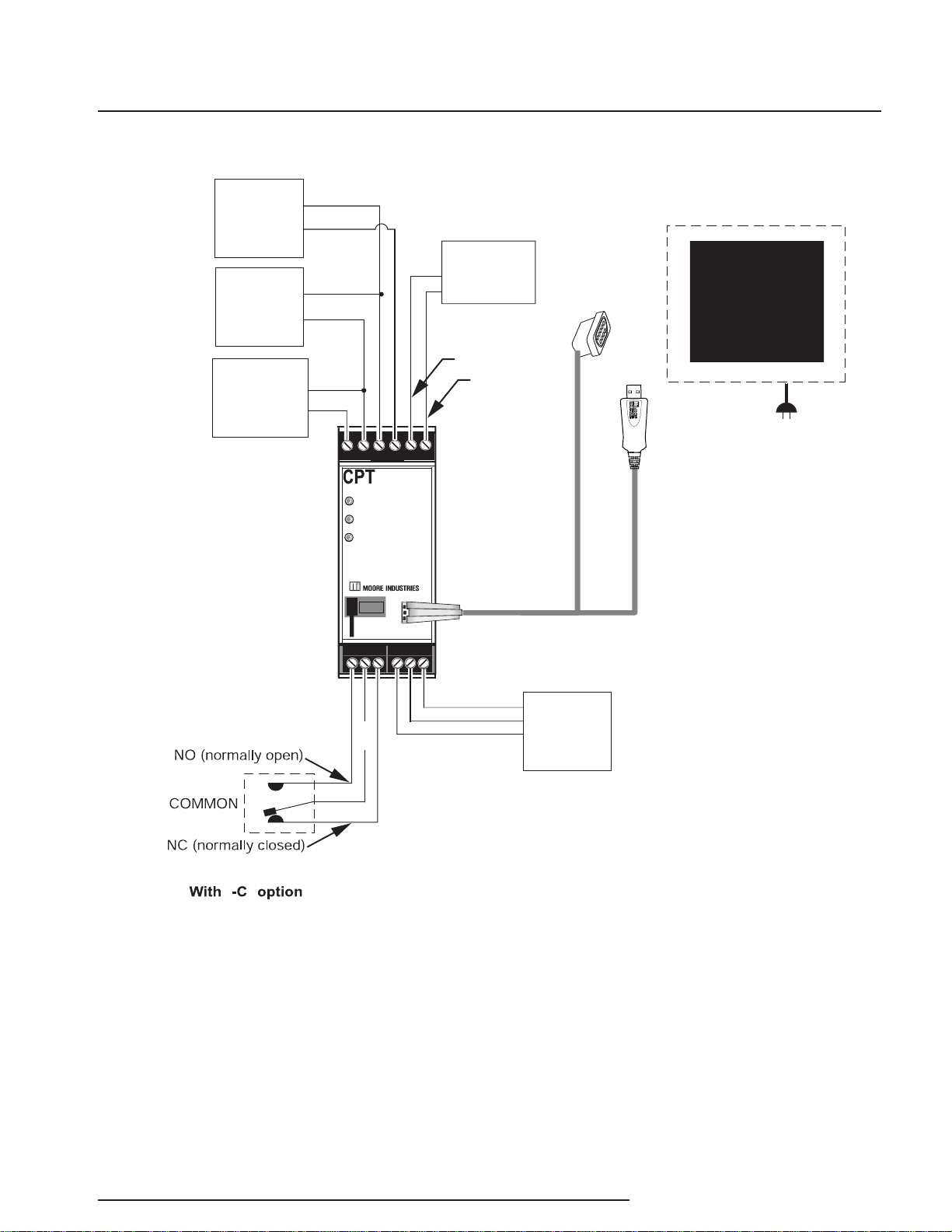

CPT

10 The Interface Solution Experts

PC-Programmable Signal

Isolater/Converter

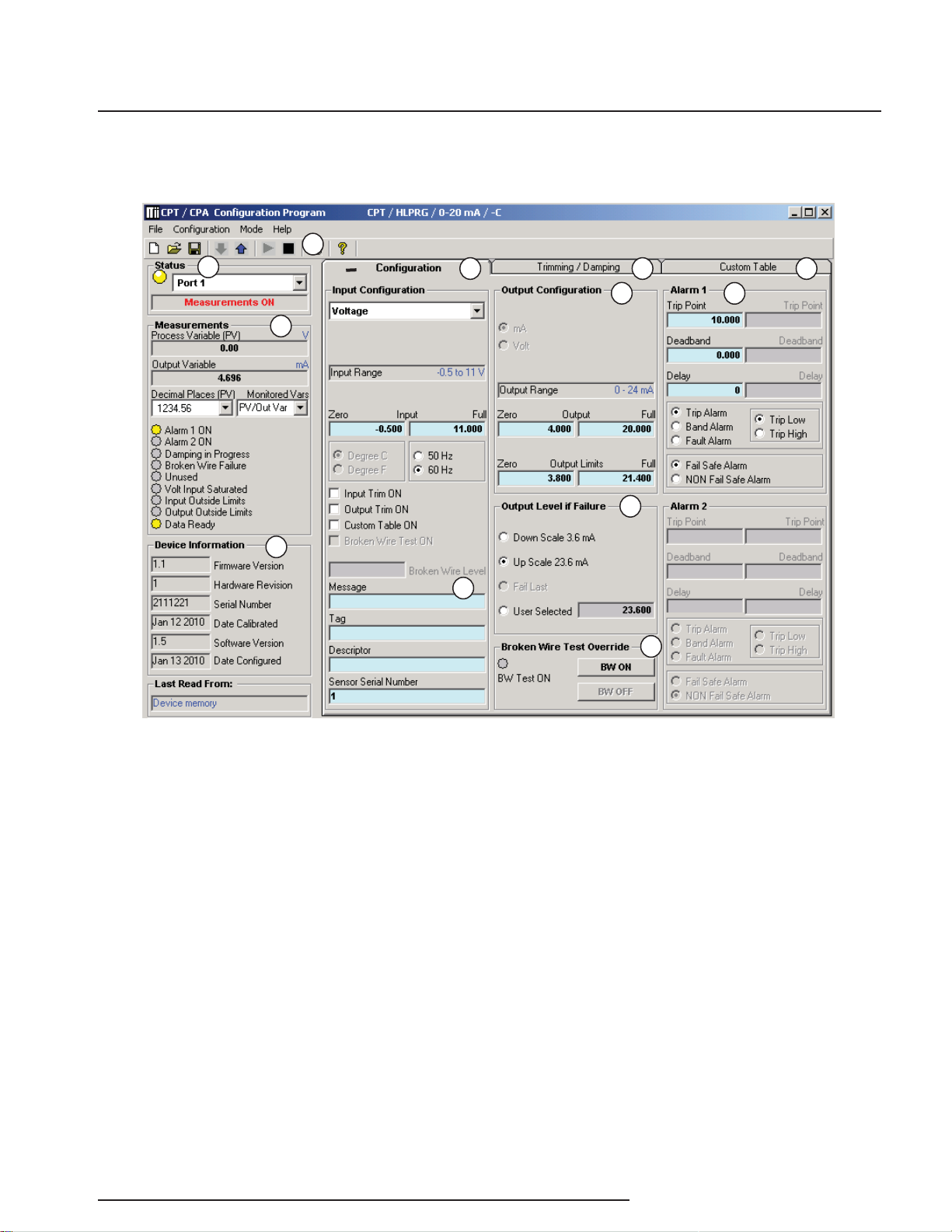

10. Alarm Parameters– Use this to choose an alarm

mode and configure as either a Trip, Fault or Band

alarm. Select whether to use as a Fail Safe or NON

Fail Safe Alarm. You may also choose a Delay (0-

120sec) and a Deadband (0-100%). Refer to the

Alarms section for a complete description.

11. Trimming/DampingTab– Selecting this

parameter allows you to perform Sensor Trim, Output

Trim and Output Damping functions. Refer to the

Trimming/Damping section for a complete description.

12. CustomTableTab– The CPT has two modes of

operation: linear mode and custom mode. In linear

mode, the scaled output is proportional to the scaled

input. In custom mode, reached by selecting the

Custom Table Tab, you define a special linearization

function. Refer to the Custom Table section for a

complete description.

Configuration

Output Level if Failure

In the Output Level if Failure section you will notice

Down Scale and Up Scale selection. Using its output,

the CPA can be configured to provide a special

warning of a breakdown or failure. Use this setting to

configure the instrument to drive its output either up or

down when a failure is detected. For current outputs,

limits are 3.6mA (downscale) and 23.6mA (upscale);

for voltage outputs, limits are -0.5V (downscale) and

11.0V (upscale).

When a failure is detected, the “Fail Last” feature, if

enabled, holds the last measured value before the

failure occurred.

If the “User Selected” feature is enabled, you may

enter any value, within the range, to view at the output

when a failure is detected.

Broken Wire Test Override

The CPT monitors your primary variable.If the

monitored value falls equal to or below a set value,

then a state of Broken Wire is declared.

Select the value of the primary variable which will

be considered “failure” and place it in the “Broken

Wire Level” text box.The range of this value must be

higher than zero (0.00mA or 0.00V) and less than the

“Zero Input Range”. Normally, a value of 0.1 or 0.2 is

sufficient.

When a failure is detected, “Broken Wire Failure” in the

Process Information section will light along with the

associated “Broken Wire” light(s) to indicate a problem.

If you are using theTrip or Band Alarm function, your

alarm status will remain unchanged as a result of

the failure. If the Fault Alarm is enabled, the alarm

is activated and resets once the failure has been

corrected.

In order to activate Broken Wire detection, you must

check the “BW ON” box and enter your selected

“failure” value.

Note:

Once you have configured all parameters,

download to the unit by either selecting “Download

Configuration” in the Configuration dropdown menu

located in the Communications bar or by clicking the

button.