Page 4

SCX

Options

The SCX is available with the following options:

RF Option — RFI and EMI protection to 50 V/m –

abc -0.1% of full-scale when tested according to

SAMA standard PMC 33.1 (not available for ECD

Housings).

RTB Option — Removable terminal block for DIN-

style units only.

WTD Option — Water-tight enclosure for ECD

housed units meeting NEMA 4 and SAA Type N

(IP65) requirements.

For information on availability of other SCX options,

contact your local Moore Industries’ Sales Represen-

tative.

Serial/Model Number. Moore Industries uses a

serial number-based tracking system to maintain

historical records on each individual product that we

sell or service. The model number contains impor-

tant configuration information about the product to

which it corresponds. Together, the serial and model

numbers provide the factory, and the user, with

information regarding the unit’s history and functional

configuration.

If service information is required, you must provide

the factory with the unit’s serial number. Providing

the model number is also important when technical

assistance is required. The serial and model num-

bers for PC units is etched into a stainless steel tag

on the front of the unit. For DIN-style and ECD units,

these numbers are printed on a label and affixed to

the side of each unit.

The model number contains information about the

configuration of the unit as it was shipped from the

factory. The following model number example

identifies the significance of each field of the SCX

model number.

Introduction

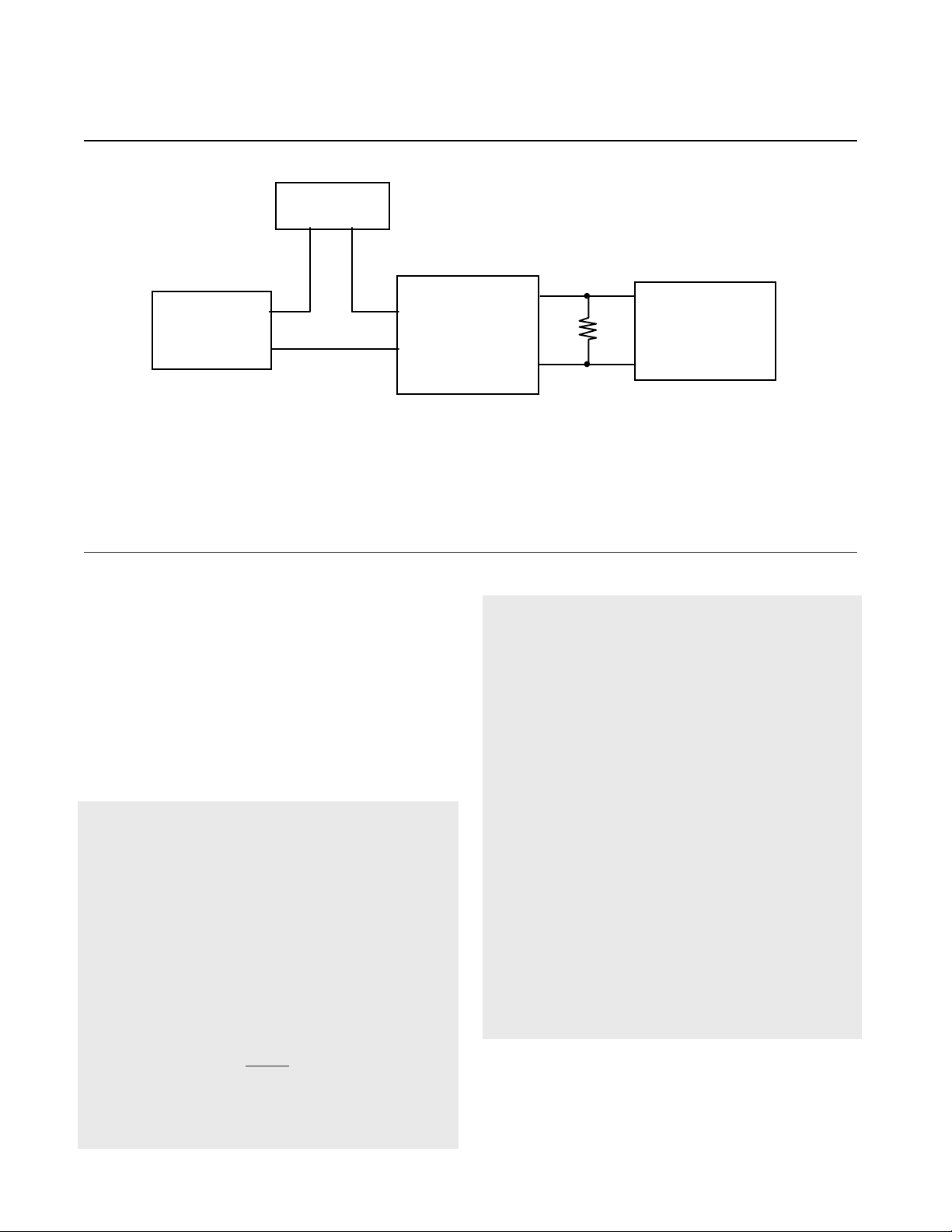

Moore Industries’ Signal Current Isolator (SCX) is a

process instrument that accepts a process variable

current input and provides an isolated current output.

This manual contains descriptive, calibration, and

installation information for the SCX. Notes are

presented in this manual to help you avoid minor

inconveniences while calibrating or installing this

instrument.

Description

The SCX accepts a 4-20 or 10-50 milliampere (mA)

input and outputs a proportional, isolated process

variable signal of the same value. Units with 10-50

mA inputs can be factory-configured to output 4-20

mA (not with ECD Housings). Units configured with

4-20 mA inputs have 4-20 mA outputs only. The

input and output are factory configured to user

specifications.

Power requirements for the SCX vary depending on

the combined input/output configuration of the unit.

Table 1 listed the voltage drops (requirements)

considerations for the SCX.

The SCX has no visual indicators, but does have one

adjustment; the TRIM potentiometer (pot). The TRIM

pot is located on the front panel and is used to adjust

the output signal for a precise span value.

The SCX is available in three basic housing styles;

the hockey-puck (HP), DIN-style, and economy DIN-

style (ECD). Functionally they are identical. The

housing style you select should be based on the

application and the environment in which the unit is

to be used.

Table 1 contains the operational and performance

specifications of the SCX.