Page 4

SIX

Introduction

Moore Industries’ Signal Isolator/Converter (SIX) is a

DIN-style, loop-powered device, used to provide

complete isolation of instrumentation input and

output. This helps eliminate faulty readings in

measurement and control equipment caused by

ground loops, electrical interference, or motor noise.

This manual provides a brief description of the SIX, a

list of performance and functional specifications, a

calibration procedure, operations notes, and trouble-

shooting information.

Notes and Cautions, where they appear in text or

illustrations, are provided to assist the user in

avoiding operational inconveniences (Notes), or

practices that otherwise might result in damage to

the unit (Cautions).

Description

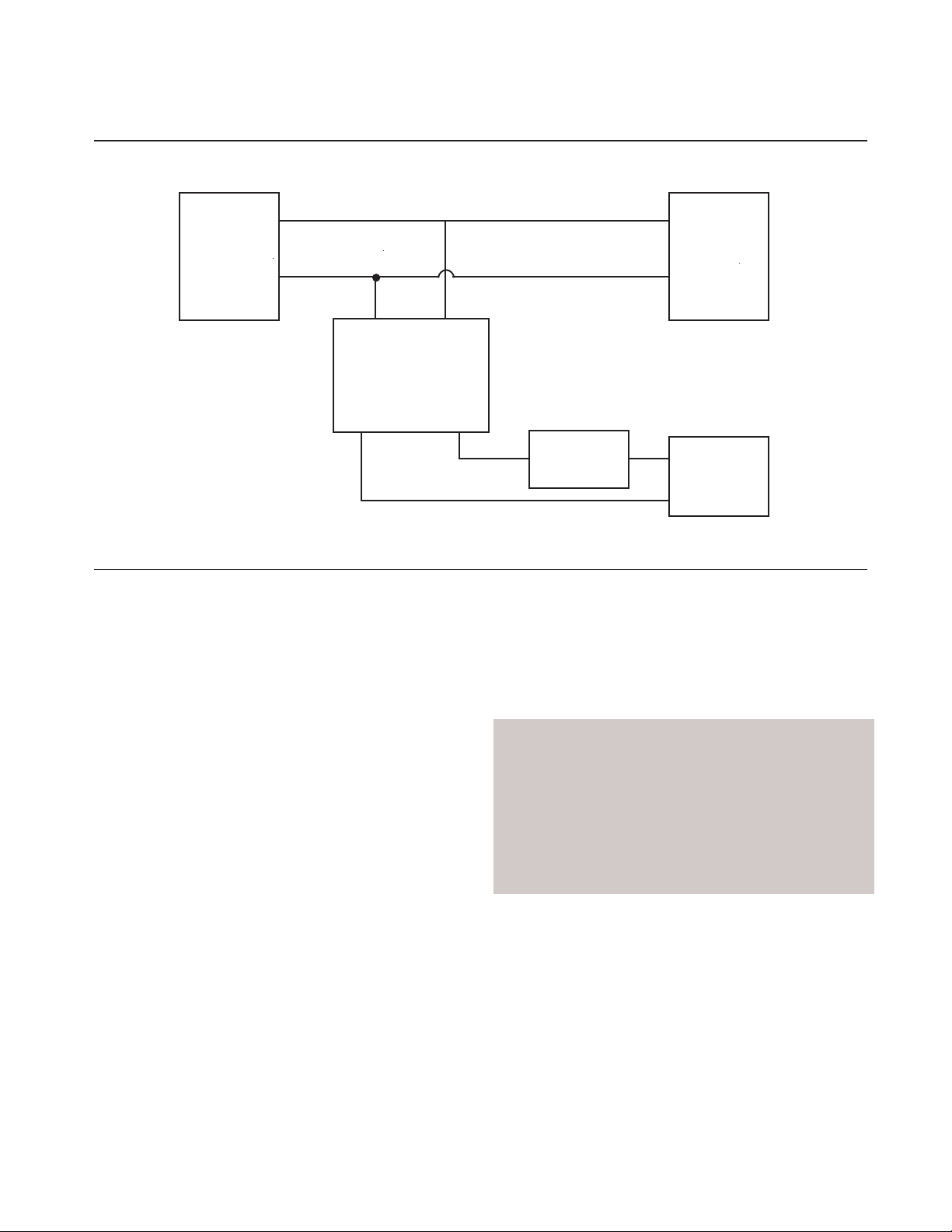

The SIX is loop-powered. When connected in a 12-

42 Vdc loop, it converts a standard process current

or voltage signal to a proportional, isolated 4-20 or

10-50 mA output; breaking the galvanic path be-

tween a transmitted signal source and its receiving

device.

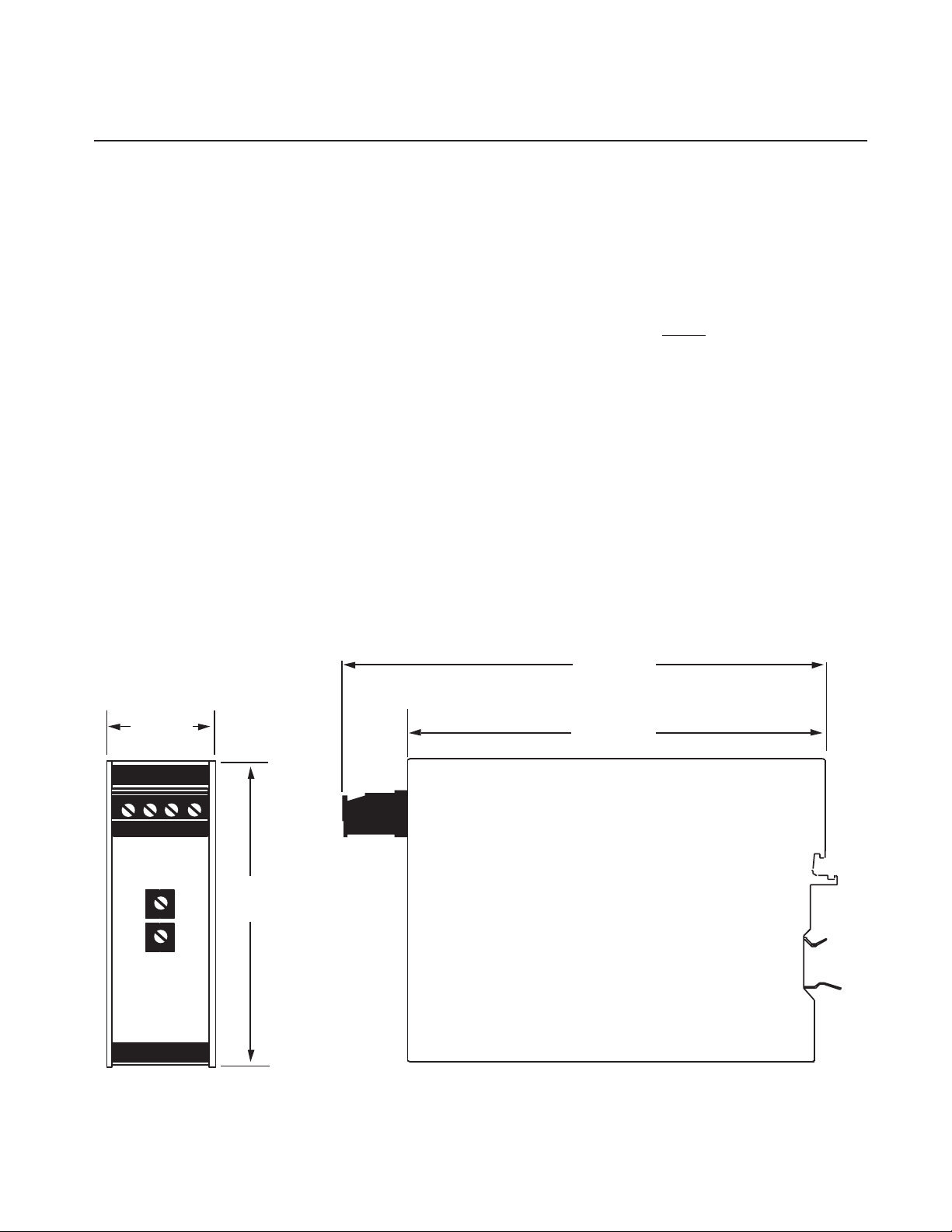

The unit is packaged in a compact, DIN-style hous-

ing that snaps easily on to G-rail mounting hardware

(DIN EN50035). This makes it ideal for use in high

density installations.

Controls

The SIX has Zero and Span potentiometers located

on the front panel of the unit. On older units these

were labeled:

for Zero, and

for Span.

On newer the words “ZERO” and “SPAN” may be

used to identify the potentiometers.

Table 1 consists of the SIX performance and func-

tional specifications.

Options

Units may be ordered with RFI-filtered terminals and

case assembly (RF Option). RF-equipped units

providesless than ±0.1% of span error when tested

at 10V/m@ 20-1000MHz.

Contact your Sales Representative or Moore Indus-

tries for more information on available SIX options

and compatible devices.

Serial Number. A complete history of every unit

sold and serviced by Moore Industries is kept at the

factory. This data is keyed to each unit’s serial

number. If service data is required on an SIX,

providing the factory with the unit serial number will

allow our highly skilled technicians to better assist

you.

The SIX serial number is located on a label affixed to

the side panel of the unit.

Model Number. Moore Industries' model numbers

identify the type of instrument, functional character-

istics, operating parameters, any options ordered,

and housing type. If all accompanying documenta-

tion for a unit is missing, the model number may be

used to obtain technical information.

The model number for the SIX is located on the same

label as its serial number.

The example following Table 1 is provided to assist in

deciphering the fields of the SIX model number.

Calibration

Prior to unit shipment, each SIX is calibrated and

tested according to Moore Industries’ strict quality

control guidelines. It is recommended, however, that

a bench check of potentiometer settings and output

levels be performed before placing the SIX into

service.