SDY

6 The Interface Solution Experts

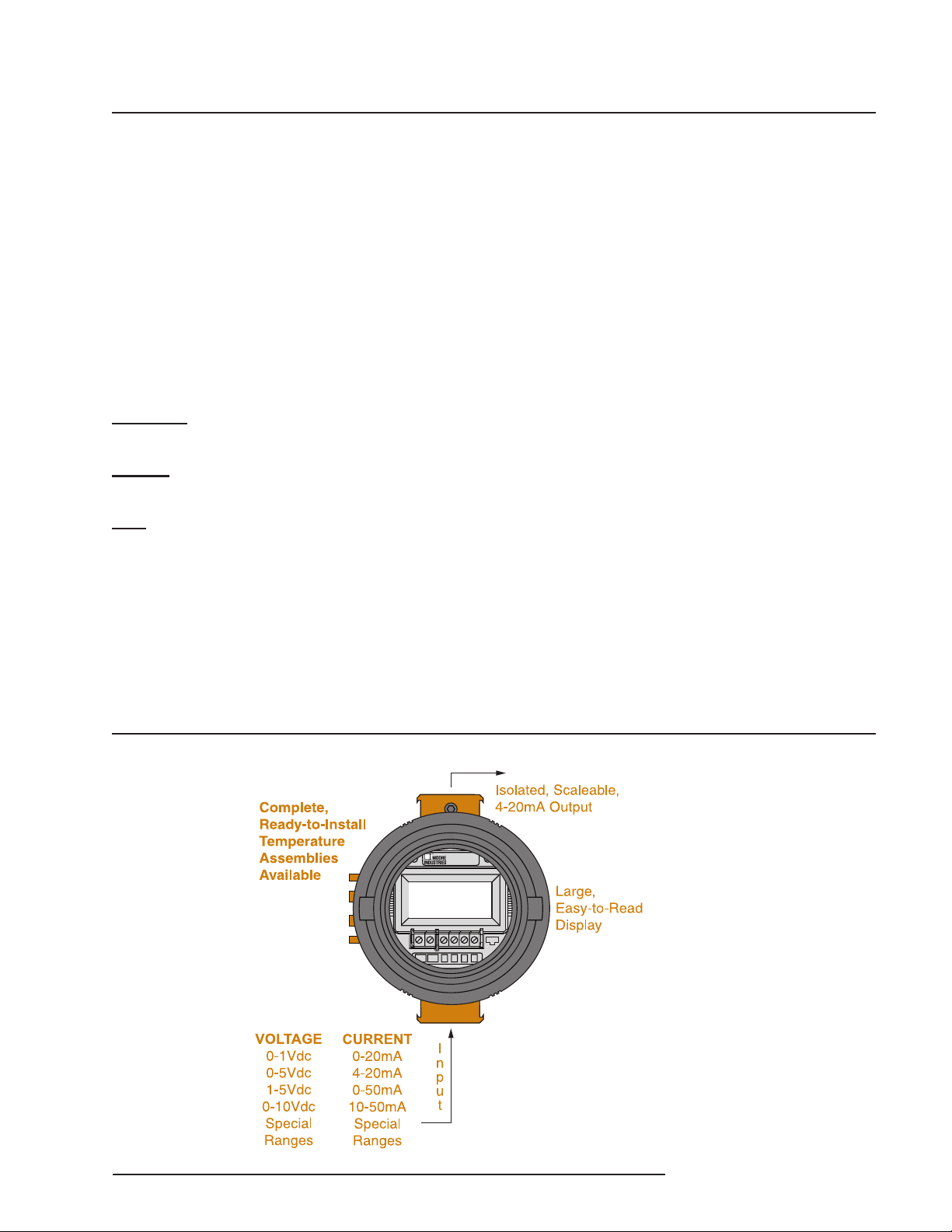

PC-Programmable Signal

Isolator/Converter with Display

Installing the

Conguration Software

Refer to Table 1 for the equipment needed.

1. Insert the Moore Industries Interface

Solution PC Conguration Software CD

into the CD drive of the PC. Access the

CD and open the SDY SIY TDY TRX

TRY 64 bit PC Conguration software

folder.

2. Double-click the installation program

located in the folder. Follow the

prompts to correctly install the program.

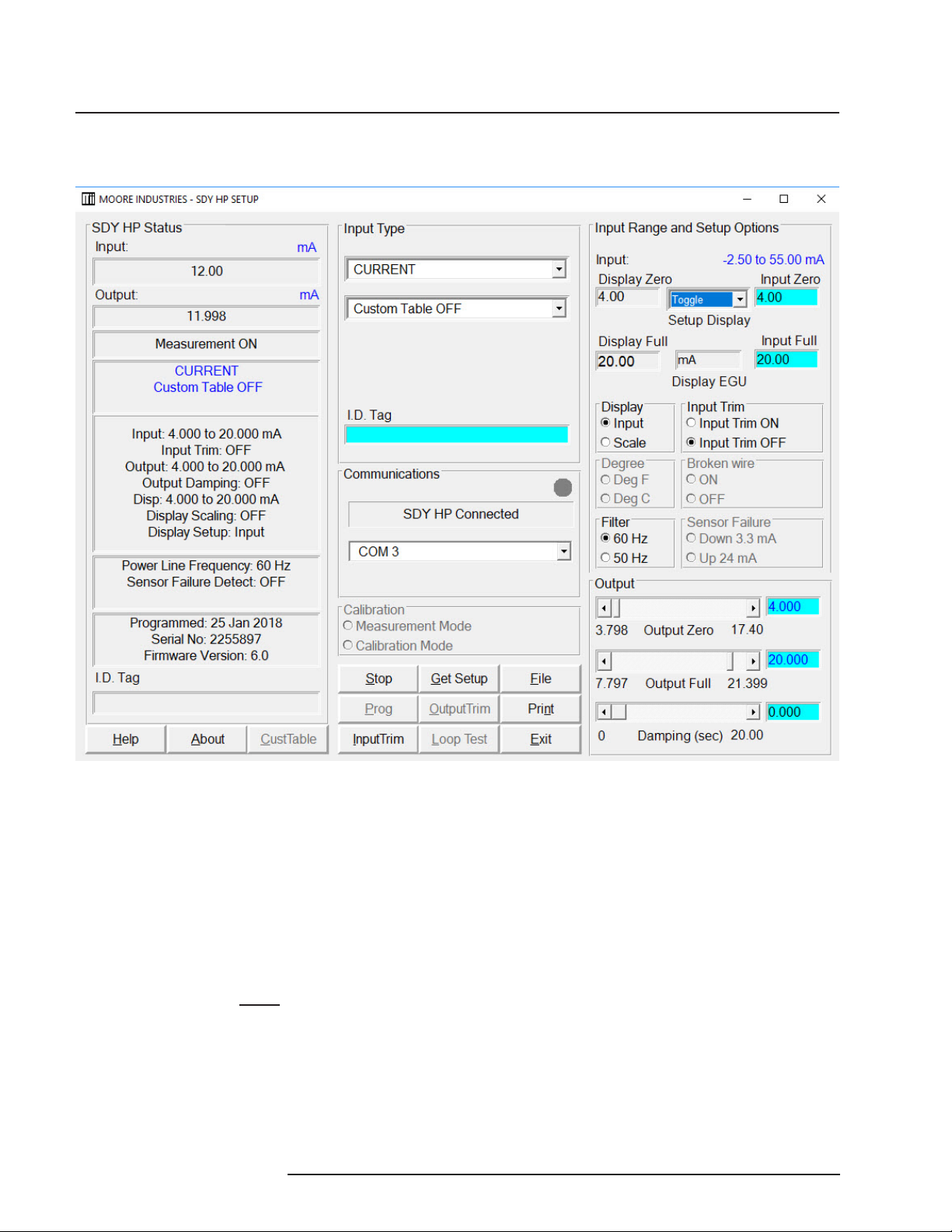

Once the Conguration Program is installed on the

PC, the SDY can be connected to equipment to

simulate input and monitor output. You can then

change the transmitter’s operating parameter

CAUTION:

Any time a connected SDY is “programmed”

by downloading a Conguration File into memory,

ALL of the conguration parameters resident

in the transmitter memory at the time of the

download are OVERWRITTEN. This includes

things like: tag name, calibration date, trim values,

etc.

Conguration

Conguring the SDY consists of:

1. Checking to verify that the unit ordered is in fact

the one received and that it has been correctly

calibrated by the factory according to the order.

2. Installing the SDY Conguration Software by

following the directions on the label.

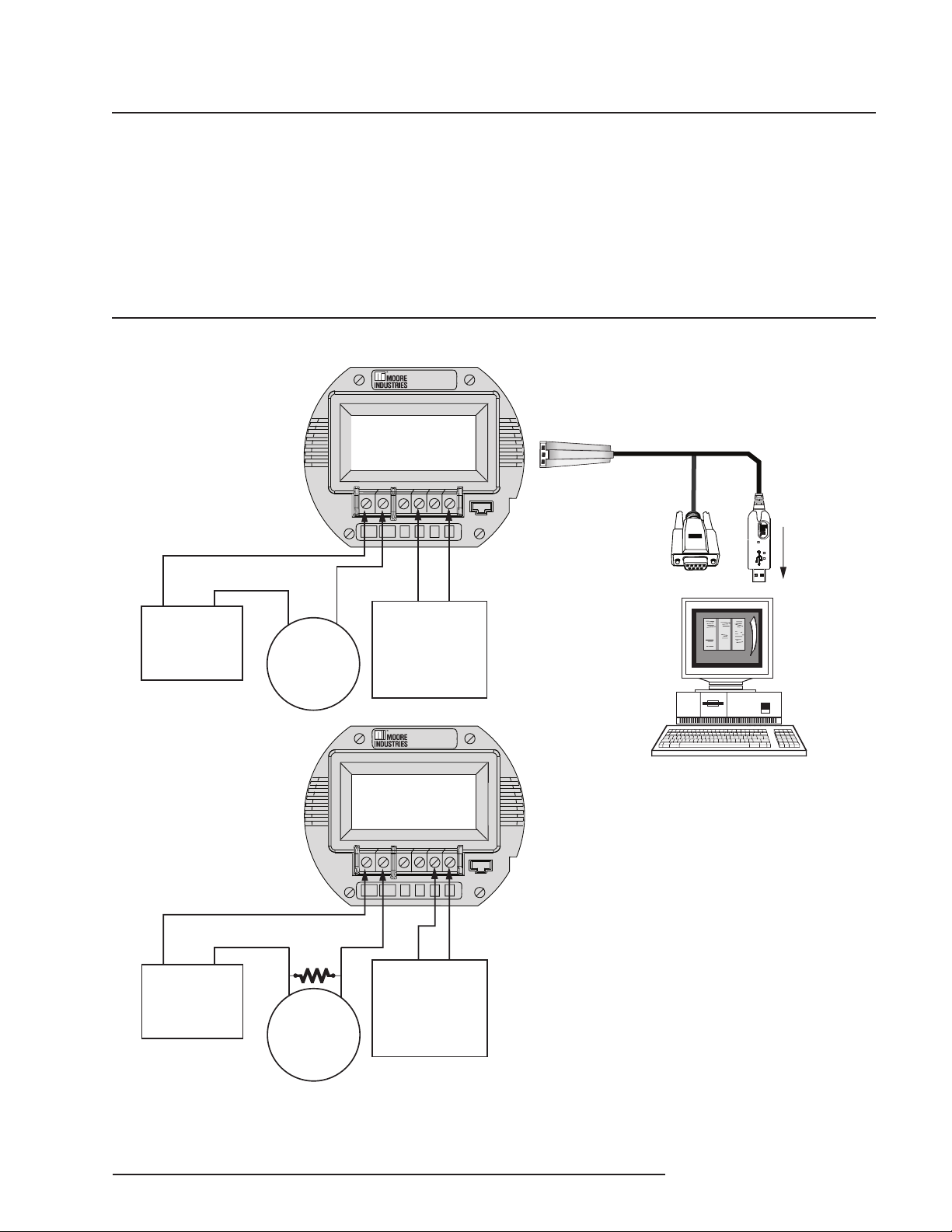

3. Connecting the SDY to a PC and test setup,

running the SDY PC Conguration Program to

check for correct unit tagging, input type and

range settings, and output zero/span trim.

Prior to shipment, our team of skilled technicians

subjects every SDY to rigorous testing. Every

product Moore Industries manufactures, sells, and

services is guaranteed to meet the strict quality

standards that our company demands.

Even if a unit has been congured to your

specications by the factory (factory calibration),

it is a good idea to perform a bench check. In

addition to providing a safe means of uncovering

any unit damage that may have occurred during

shipping, the procedures aord the user the

opportunity of becoming familiar with SDY operation

in a testing environment that is separate from the

intended process or application.

Note:

The procedures in this section should be carried

out in an environment considered appropriate for

the general testing of electronic equipment, rather

than in the eld. Use a technician’s bench or

similar, lab-type environment.

Specication

Accurate to ±0.05% of span for

the intended application

18-42Vdc, ±10% (10-42VDC if

no load resistor is used)

250Ω, ±0.01%

Accurate to ±0.025%

Device

Current or

Voltage Source

Power Supply

Precision Load Resistor

(optional)

Multimeter

Personal

Computer

Moore Industries’

Communication Cable

Table 1. SDY Conguration Equipment

Microsoft Windows based PC;

16Mb free RAM; 20MB free disk

space on hard drive

Microsoft Windows XP, Vista or

7 and 1 (one) serial port or one

available USB port (with optional

USB cable)

Non- isolating (PN 803-040-26)

Isolating (PN 803-039-26)

Fuse Protected USB Cable (PN

804-030-26)