ADDITIONAL GENERAL SAFETY RULES

(SUPPLEMENT TO MAIN INSTRUCTION BOOK)

1. Additional care must be taken with H.P. Drills due to the increased

transport height. Good driving sense in avoiding low obstacles

especially overhead power lines and cables, bridges, trees and other

factors which may effect transport and use of H.P. Drills.

2. Always unfold H.P. Drills in raised position with transport pins

engaged and mechanical wing locks dis – engaded trying to

unfold wings whilst transport locks are still engaged can damage

main frame.

3. Always transport H.P. Drills with hopper empty, and do not exceed

25km/h.

4. Never operate bout markers unless area is clear.

HITCHING

1. Attach tractor to drill using pick up hitch or clevis.

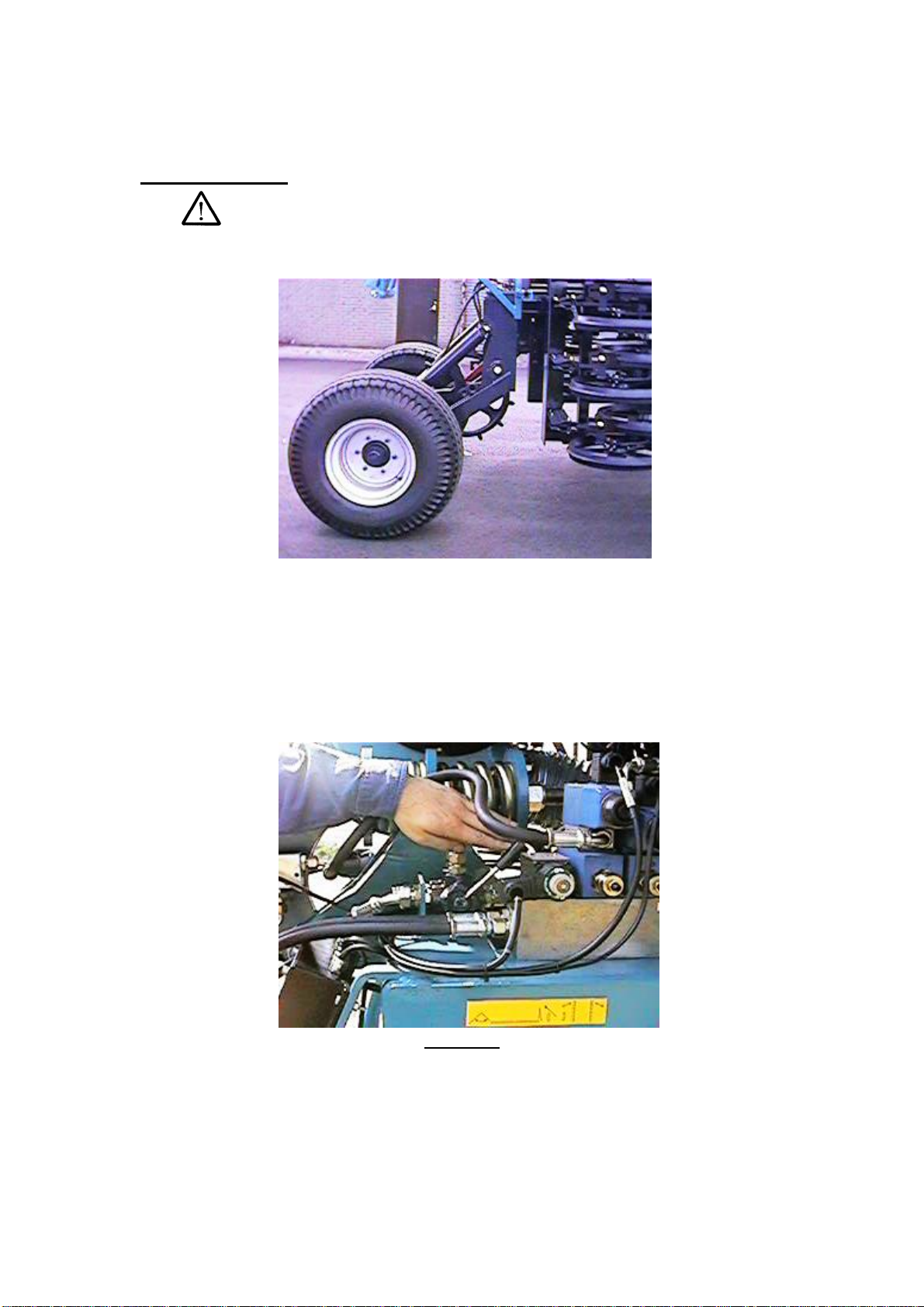

2. Attach the pipes of the hydraulic fan to the tractors priority valve (if

fitted) a cap fitted with a chain identifies the pressure hose.

The return hose must have unrestricted return access to hydraulic tank

(i.e ‘dump valve’), otherwise damage may occur . If in doubt refer to your

tractor supplier.

3. Attach the hoses for the Head Land Control (HLC) system, Must be

fitted to double acting spool.

4. Connect HLC hand grip onto the spool lever that is being used to run

HLC system.

5. Connect HLC hand grip cable to the cable from the HLC control box.

6. Connect the other cable from the HLC control box to the tractors

standard 12V power source.

7. Connect the cable from the tram – lining system to the tractors 12V

Supply.

8. Connect lighting cables and braking hoses to the appropriate places.

9