TYCROP Manufacturing Ltd. QuickPass Top Dresser Setup Manual

Table of Contents Page iii

Table of Contents

Setup Instructions.............................................................................................................1

How to Set Up the Chassis........................................................................................1

QP300 Only......................................................................................................2

QP450 Only......................................................................................................2

How to Install the Honda Engine ...............................................................................2

How to Install the Tow Vehicle Hydraulic Option.......................................................5

How to Install the 2 Way Switch Option.....................................................................8

How to Install the QuickPass 300 Red Hopper .......................................................12

How to Install the QuickPass 450 Yellow Hopper ...................................................13

How to Install the Hopper Insert ..............................................................................15

Maintenance Instructions ...............................................................................................18

How to Change the Belt Assembly ..........................................................................18

How to Change Tires ...............................................................................................21

How to Change an Outside Tire.....................................................................21

How to Change an Inside Tire .......................................................................21

How to Upgrade the Honda Engine Fuel Tank to the TyCrop 9L Fuel Tank...........21

How to Remove the Old Tank........................................................................21

How to Install the New Tank ..........................................................................22

Figures

Figure 1: Tighten nylon locking nuts to hitch tube .....................................................1

Figure 2: Install plastic washers over welded bolts ...................................................1

Figure 3: Install flat washers over welded bolts.........................................................1

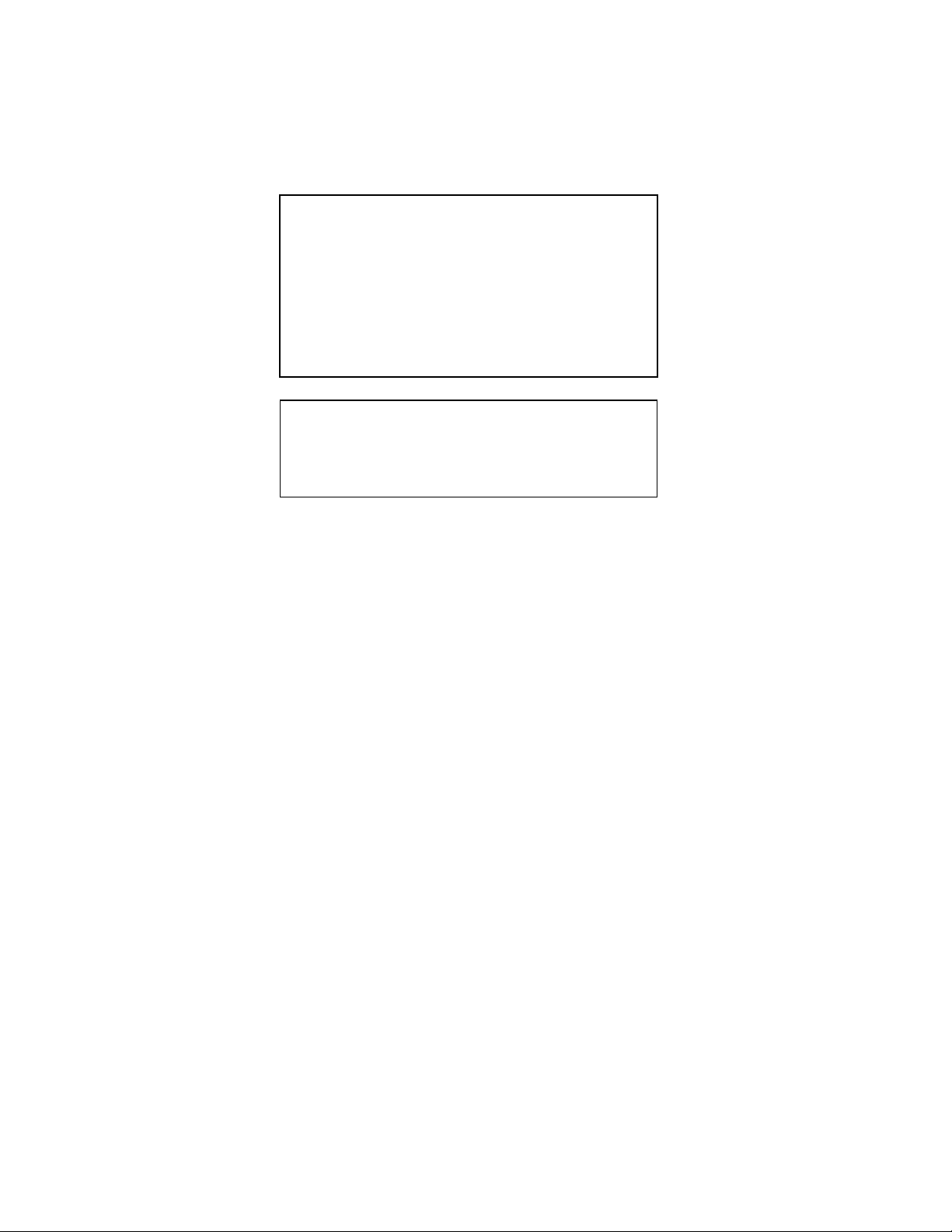

Figure 4: Install bolt and lock washer through gate-adjusting arm ............................2

Figure 5: Place the gate metering bar .......................................................................2

Figure 6: Install metering bar sticker..........................................................................2

Figure 7: Decal Placement ........................................................................................3

Figure 8: Remove battery plugs.................................................................................3

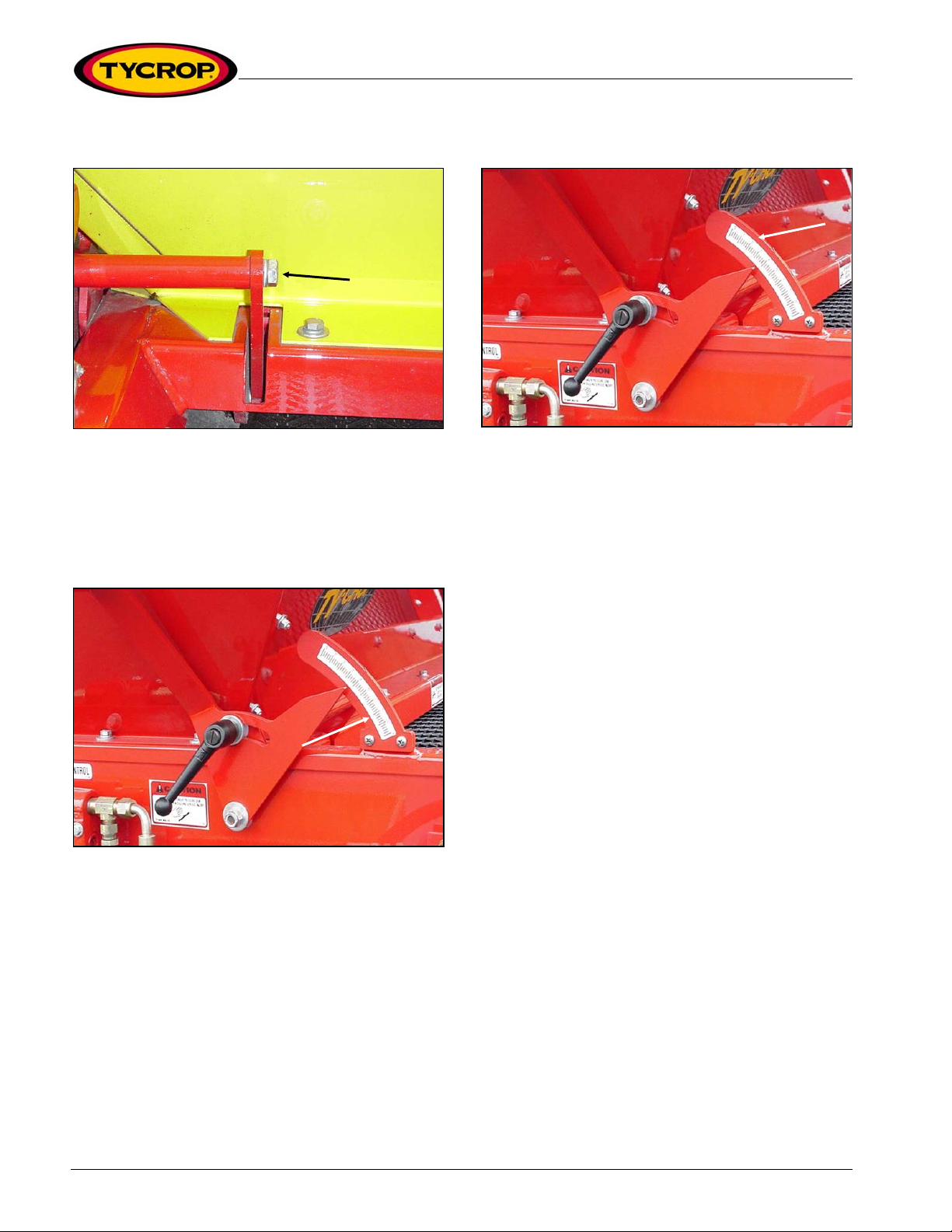

Figure 9: Connect hydraulic hoses to fittings.............................................................3

Figure 10: Connect hydraulic hoses to ports .............................................................4

Figure 11: Remove bolts and black plug ...................................................................4

Figure 12: Install hood stop adjuster plate.................................................................4

Figure 13: Schematic of hydraulic connections for Honda engine ............................5

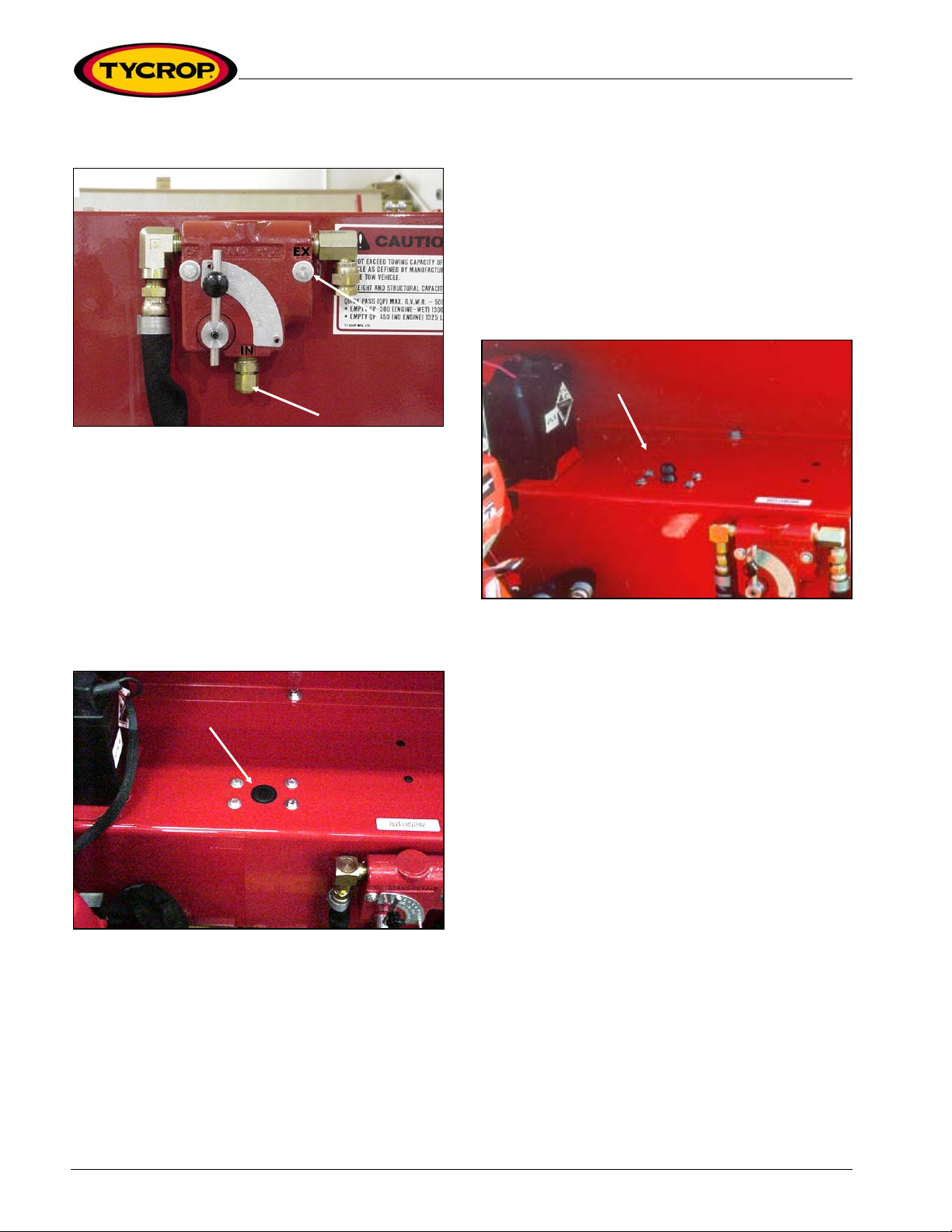

Figure 14: Mount weight case onto hitch...................................................................5

Figure 15: Attach pogo stick on hitch.........................................................................6

Figure 16: Connect return hose and hydraulic fitting.................................................6

Figure 17: Schematic of hydraulic connections for weight case................................7

Figure 18: Remove existing hose ..............................................................................8

Figure 19: Remove hydraulic line clamps from weight case .....................................8

Figure 20: Remove male-to-male junction fitting .......................................................8

Figure 21: Schematic of on/off pendant switch and hydraulics .................................9

Figure 22: Loosen hose at end of tee fitting on ‘B’ port...........................................10

Figure 23: Schematic of electrical components.......................................................11

Figure 24: Remove hopper mounting bolts from chassis ........................................12

Figure 25: Install left and right hopper walls ............................................................12