Page10 HANDFEDCREASING

SettingtheAdjustableSideLay

Placethepaperstackontotheloadingtableandslideuptothefixedsidelay.

Positiontheadjustablesidelayuptowardsthepaperstack,allowagapofapprox.

0.5mm(1/64inch)betweenthepaperandthesidelay.

SettingtheRollerTiltMechanism

Therollertiltmechanismhasbeendesignedtocompensateforwhenthecreasing

positiononthesheetisnotsquare.Thiscouldbeduetoaninaccuracyinthemediaorif

therollertiltmechanismhasbeenincorrectlyset.Themechanismwillbesettozero

(square)whenthemachineissupplied.

Tosetthemechanism,unlocktherollertiltknoblocatedbelowtherollertiltinghandleby

turninganti-clockwise.Movetherollertilthandleleftorrightinordertocompensatefor

anyinaccuracy.Whenthepositionisset,ensuretolocktherollertiltknobbefore

operatingthemachine.Repeattheaboveprocedureuntilthecreasingpositionissquare.

Settingthepositionsofdrivewheelsandhubs

Itisimportantthatthedrivewheelsanddrivehubsontherollershaftsarearrangedevenly

acrossthewidthofthemediabeingcreased.Thisisdonetoensurethatthemediais

accuratelydrivenandsupportedthroughtherollers.

Thedrivewheelsandhubsarefixedtotherollersbymeansofagrubscrew.Tolocate

thisgrubscrewtherollerscanberotatedbyoperatingthemotormanually.

DONOTROTATETHEDRIVEROLLERSBYHAND.

Tooperatethemotorsmanually,switchthemachine‘on’attheEmergencyStopswitch.

Followingthearrowsonthedisplayunit,movetheselectionswitchtothelefttoselect

Tools,thedisplaywillnowshowtheToolssub-menu.Pressthesystemswitchdownand

thenmovetheselectionswitchtotheleftortotheright,torotatetherollersinshortpulses.

Thisprocedureshouldberepeatedwheninstallingperforatingbladesandanvilsontothe

drivewheelsandhubs.

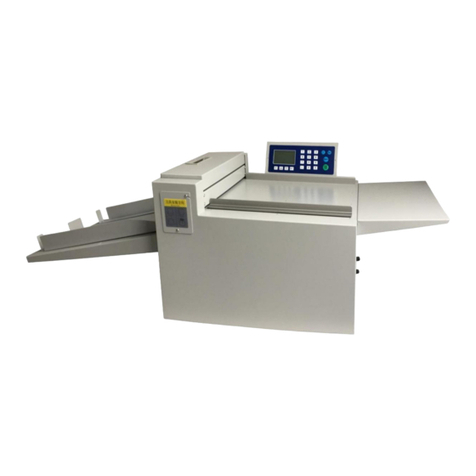

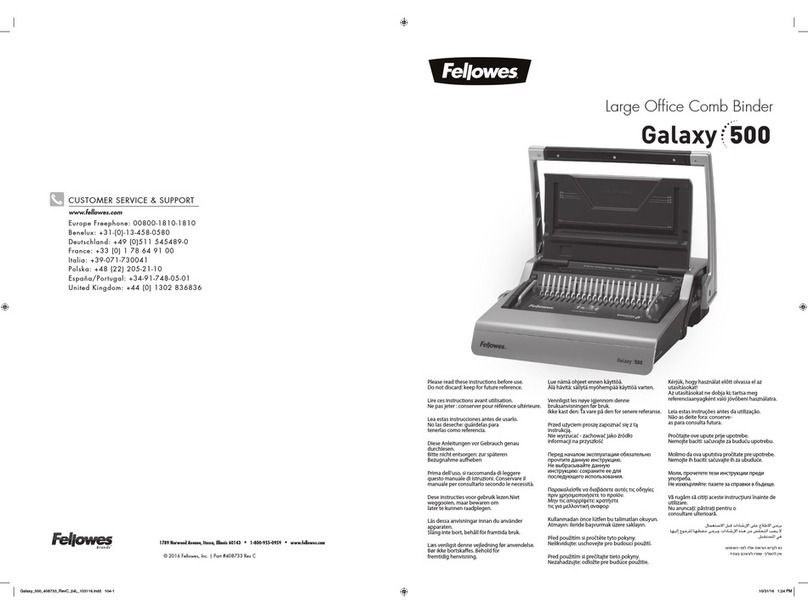

FIG10.1

Lifttheexitguardtoseeifthegrubscrewsinthedrivewheelsandhubscanbeseen.Ifthe

grubscrewscannotbeseen,lowertheexitguardandrotatetherollersbymovingthe

selectionswitchtotheleftortotheright.Loosenthedrivewheelsandhubswitha2mm

allenkey.ArrangethedrivewheelsandhubsasshowninFIG10.1.Inordertoavoid

markingonsometypesofmediaensureagapbetweenthedrivewheelsandhubs.

OperatingtheDigicreaser