Operator Manual DigiBook 150

2

Rev. 1.00-C

Summary

1INTRODUCTION ________________________________________________________ 4

1.1 CE MARK__________________________________________________________________________ 5

1.2 SAFETY SIMBOLS __________________________________________________________________ 6

1.3 SYMBOLS OF PROHIBITION AND OBLIGATORINESS ___________________________________ 7

1.4 THE SAFETY DURING THE USE OF THE MACHINE _____________________________________ 8

1.4.1 General ________________________________________________________________________ 8

1.4.2 Safety warnings __________________________________________________________________ 8

1.5 SAFETY CLOTHING_________________________________________________________________ 9

1.6 INSTALLATION OF ELECTRICAL CABLES AND HOUSES _______________________________ 10

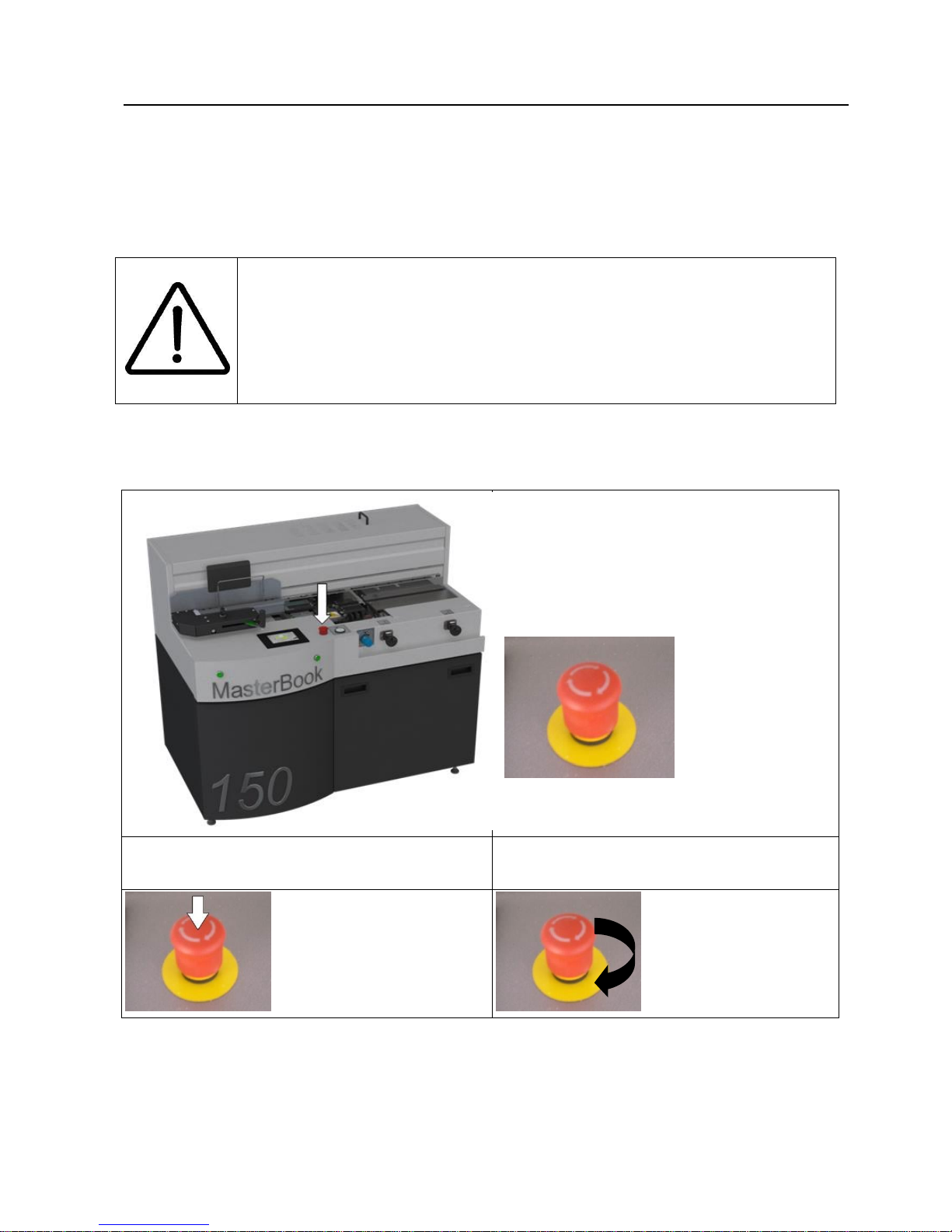

1.7 SAFETY EQUIPMENTS IN THE MASTER BOOK ________________________________________ 10

1.7.1 Emergency button _______________________________________________________________ 10

1.7.2 Green button To start cycle ________________________________________________________ 11

1.7.3 Protection plate of the milling station ________________________________________________ 11

1.7.4 Main Switch ____________________________________________________________________ 12

1.8 RESIDUAL RISKS__________________________________________________________________ 13

1.9 PURPOSES________________________________________________________________________ 14

1.9.1 Not provided uses, prohibited uses __________________________________________________ 14

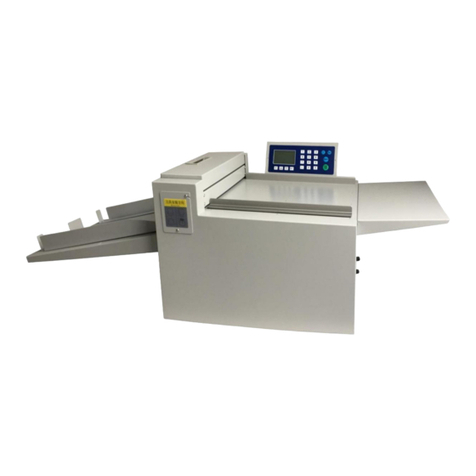

2TECHNICAL SHEET FOR MASTERBOOK 150 ____________________________ 15

2.1.1 Electrical ______________________________________________________________________ 16

2.1.2 Pneumatics_____________________________________________________________________ 16

Air quality provided to the Master Book _____________________________________________________ 17

DIN ISO 8573-1 –air quality class _________________________________________________________ 17

3STANDARD ACCESSORIES______________________________________________ 18

4TRANSPORTATION ____________________________________________________ 19

5STORAGE______________________________________________________________ 20

6LAYOUT_______________________________________________________________ 21

7POSITIONING AND WORKSPACES ______________________________________ 22

8INSTALLATION ________________________________________________________ 23

8.1 TECHNICAL STAFF FOR THE INSTALLATION_________________________________________ 23

8.2 PHYSICAL CHARACTERISTICS OF THE AREA OF PLACEMENT _________________________ 23

8.3 BOLSTER_________________________________________________________________________ 23

8.4 WEATHER PROTECTION ___________________________________________________________ 23

8.5 LIGHT____________________________________________________________________________ 23

8.6 ENVIRONMENTAL CONDITIONS____________________________________________________ 24

8.7 ELECTRICAL CONNECTION ________________________________________________________ 25

8.7.1 Ground connection_______________________________________________________________ 25

9TRAINING OF THE OPERATOR _________________________________________ 26

10 POWER ON ____________________________________________________________ 27