3

1. SAFETY1. SAFETY

1. SAFETY1. SAFETY

1. SAFETY

InstallerInstaller

InstallerInstaller

Installer

Beforecontinuinganyfurtherwiththeinstallationofthisstovereadthefollowing

guidetomanualhandling.

• The lifting weight of this stove is 53.5 kg.

• This stove is heavy. We therefore recommend that two people

should be sufficient to lift the stove. If fitting or moving the appliance

alone we recommend the use of suitable lifting apparatus.

• When lifting always keep your back straight. Bend your legs and not

your back.

• Avoid twisting at the waist. It is better to reposition your feet.

• Avoid upper body/top heavy bending. Do not lean forward or

sideways whilst handling the stove.

• Always grip with the palm of the hand. Do not use the tips of fingers

forsupport.

• Always keep the stove as close to the body as possible. This will

minimisethe cantilever action.

• Use gloves to provide additional grip.

• Always use assistance if required.

2. APPLIANCE DA2. APPLIANCE DA

2. APPLIANCE DA2. APPLIANCE DA

2. APPLIANCE DATT

TT

TAA

AA

A

This product uses fuel effect pieces, burner compartment walls andThis product uses fuel effect pieces, burner compartment walls and

This product uses fuel effect pieces, burner compartment walls andThis product uses fuel effect pieces, burner compartment walls and

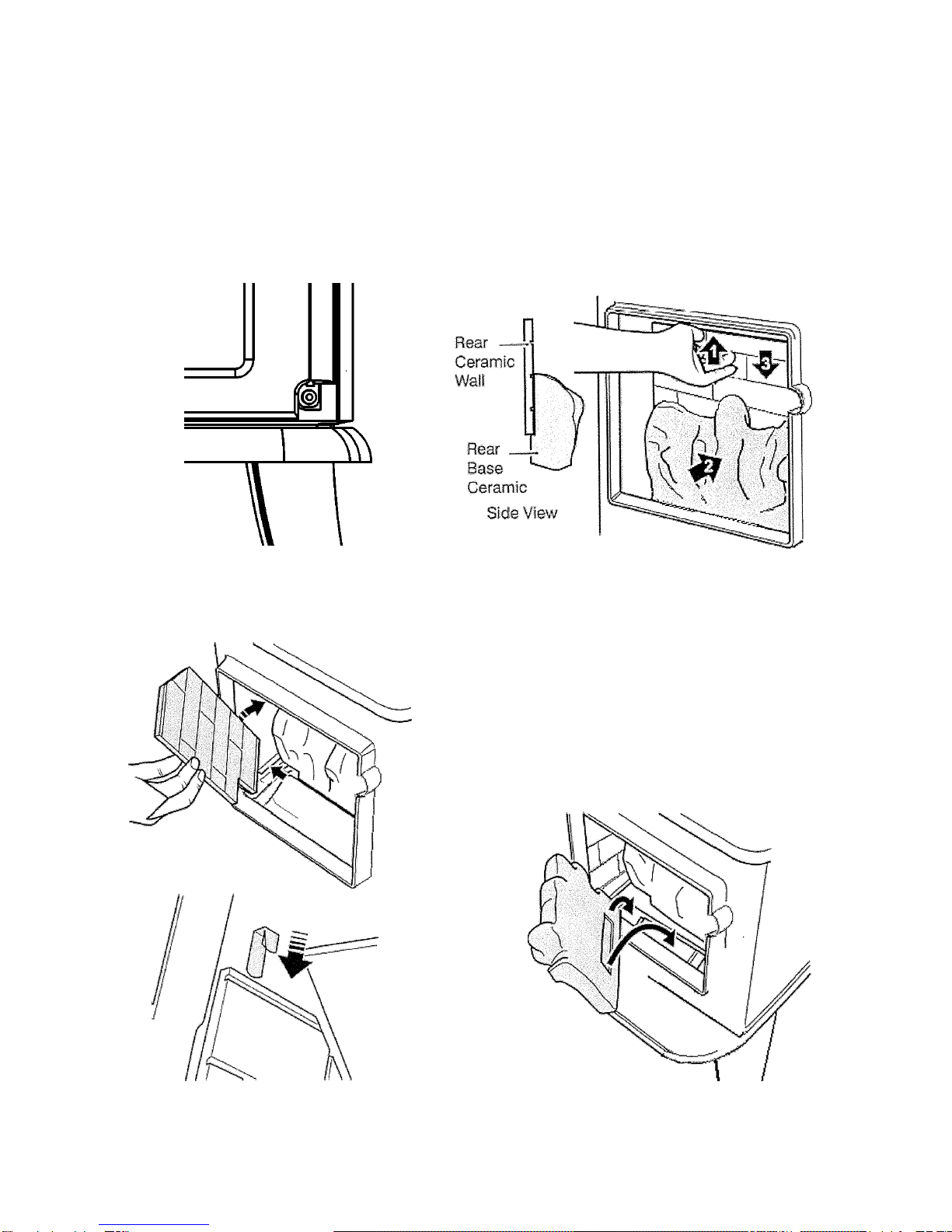

This product uses fuel effect pieces, burner compartment walls and

gasketscontaining Refractory CeramicFibres (RCF), whichare man-madegasketscontaining Refractory CeramicFibres (RCF), whichare man-made

gasketscontaining Refractory CeramicFibres (RCF), whichare man-madegasketscontaining Refractory CeramicFibres (RCF), whichare man-made

gasketscontaining Refractory CeramicFibres (RCF), whichare man-made

vitreous silicate fibres. Excessive exposure to these materials may causevitreous silicate fibres. Excessive exposure to these materials may cause

vitreous silicate fibres. Excessive exposure to these materials may causevitreous silicate fibres. Excessive exposure to these materials may cause

vitreous silicate fibres. Excessive exposure to these materials may cause

temporary irritation to eyes, skin and rtemporary irritation to eyes, skin and r

temporary irritation to eyes, skin and rtemporary irritation to eyes, skin and r

temporary irritation to eyes, skin and respiratory tract. Consequentlyespiratory tract. Consequently

espiratory tract. Consequentlyespiratory tract. Consequently

espiratory tract. Consequently, it, it

, it, it

, it

makes sense to take care when handling these articles to ensure that themakes sense to take care when handling these articles to ensure that the

makes sense to take care when handling these articles to ensure that themakes sense to take care when handling these articles to ensure that the

makes sense to take care when handling these articles to ensure that the

rr

rr

release of dust is kept to a minimum. Telease of dust is kept to a minimum. T

elease of dust is kept to a minimum. Telease of dust is kept to a minimum. T

elease of dust is kept to a minimum. To ensuro ensur

o ensuro ensur

o ensure that the re that the r

e that the re that the r

e that the release of fibrelease of fibr

elease of fibrelease of fibr

elease of fibreses

eses

es

from these RCF articles is kept to a minimum, during installation andfrom these RCF articles is kept to a minimum, during installation and

from these RCF articles is kept to a minimum, during installation andfrom these RCF articles is kept to a minimum, during installation and

from these RCF articles is kept to a minimum, during installation and

servicing we rservicing we r

servicing we rservicing we r

servicing we recommend that you use a HEPecommend that you use a HEP

ecommend that you use a HEPecommend that you use a HEP

ecommend that you use a HEPA filterA filter

A filterA filter

A filtered vacuum to red vacuum to r

ed vacuum to red vacuum to r

ed vacuum to removeemove

emoveemove

emove

any dust and soot accumulated in and around theany dust and soot accumulated in and around the

any dust and soot accumulated in and around theany dust and soot accumulated in and around the

any dust and soot accumulated in and around the stovestove

stovestove

stove before and afterbefore and after

before and afterbefore and after

before and after

working on theworking on the

working on theworking on the

working on the stovestove

stovestove

stove. When replacing these articles we recommend that. When replacing these articles we recommend that

. When replacing these articles we recommend that. When replacing these articles we recommend that

. When replacing these articles we recommend that

the replaced items are not broken up, but are sealed within a heavy dutythe replaced items are not broken up, but are sealed within a heavy duty

the replaced items are not broken up, but are sealed within a heavy dutythe replaced items are not broken up, but are sealed within a heavy duty

the replaced items are not broken up, but are sealed within a heavy duty

polythene bag, clearly labelled as RCF waste. This is not classified aspolythene bag, clearly labelled as RCF waste. This is not classified as

polythene bag, clearly labelled as RCF waste. This is not classified aspolythene bag, clearly labelled as RCF waste. This is not classified as

polythene bag, clearly labelled as RCF waste. This is not classified as

“hazardous waste” and may be disposed of at a tipping site licensed for“hazardous waste” and may be disposed of at a tipping site licensed for

“hazardous waste” and may be disposed of at a tipping site licensed for“hazardous waste” and may be disposed of at a tipping site licensed for

“hazardous waste” and may be disposed of at a tipping site licensed for

the disposal of industrial waste. Protective clothing is not required whenthe disposal of industrial waste. Protective clothing is not required when

the disposal of industrial waste. Protective clothing is not required whenthe disposal of industrial waste. Protective clothing is not required when

the disposal of industrial waste. Protective clothing is not required when

handling these articles, but we recommend you follow the normal hygienehandling these articles, but we recommend you follow the normal hygiene

handling these articles, but we recommend you follow the normal hygienehandling these articles, but we recommend you follow the normal hygiene

handling these articles, but we recommend you follow the normal hygiene

rules of not smoking, eating or drinking in the work area and always washrules of not smoking, eating or drinking in the work area and always wash

rules of not smoking, eating or drinking in the work area and always washrules of not smoking, eating or drinking in the work area and always wash

rules of not smoking, eating or drinking in the work area and always wash

your hands before eating or drinking.your hands before eating or drinking.

your hands before eating or drinking.your hands before eating or drinking.

your hands before eating or drinking.

This appliance does not contain any component manufactured fromThis appliance does not contain any component manufactured from

This appliance does not contain any component manufactured fromThis appliance does not contain any component manufactured from

This appliance does not contain any component manufactured from

asbestos or asbestos related products.asbestos or asbestos related products.

asbestos or asbestos related products.asbestos or asbestos related products.

asbestos or asbestos related products.