Report No.: 300-ELAB-2526-EPA Rev4 110821

Date: 11.08.2021

Initials: JSA/

Page 2 of 49

300-ELAB-2526-EPA Rev4 110821

1. Introduction.........................................................................................................................4

General ...........................................................................................................................4

Report revision history overview .........................................................................................4

Revision 1 changes ...........................................................................................................4

Revision 2 changes ...........................................................................................................4

Revision 3 changes ...........................................................................................................4

Revision 4 changes ...........................................................................................................5

List of Issues found (ref. Sanzhez email of June 10. 2021).....................................................5

Scope of testing................................................................................................................8

Site.................................................................................................................................8

Participants ......................................................................................................................8

DTI staff ..................................................................................................................................8

Client staff ...............................................................................................................................8

Test specimen ..................................................................................................................8

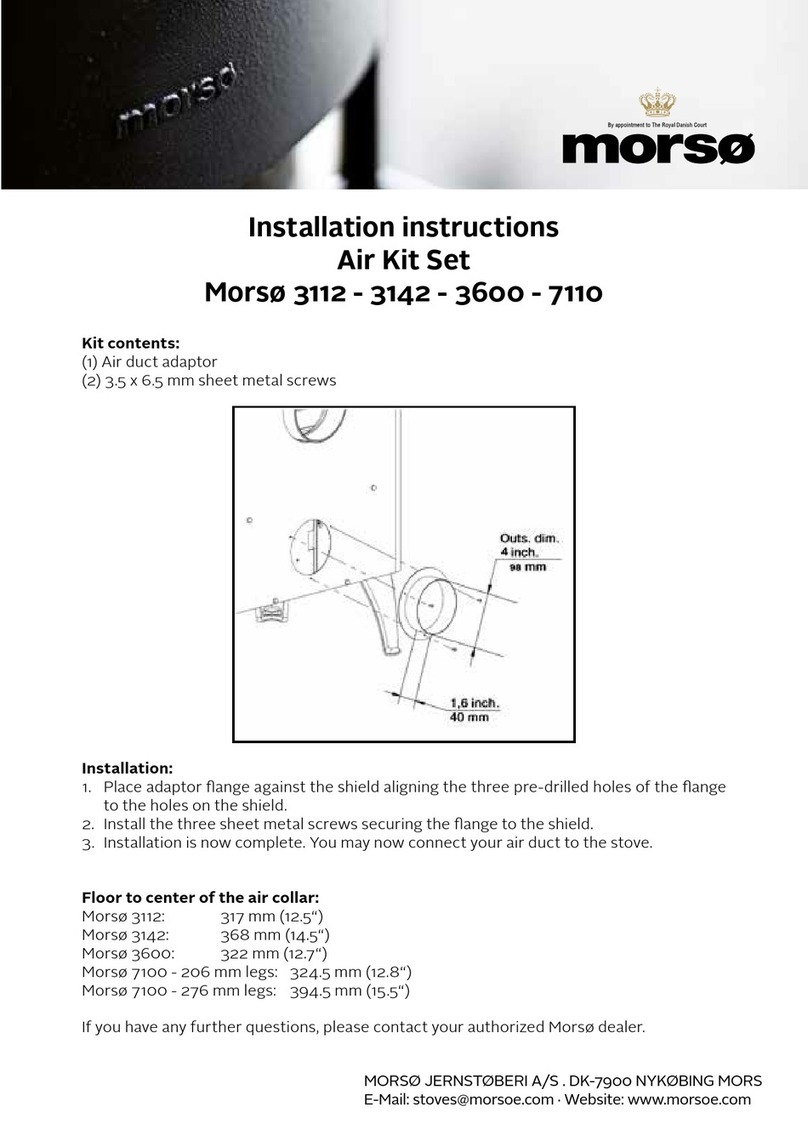

Description of the wood heater ...........................................................................................9

2. Aging prior to testing .......................................................................................................... 10

3. Summary of test results......................................................................................................11

Test schedule ................................................................................................................. 11

Main results ................................................................................................................... 11

Summary of the CS+HF and LF tests the 02-09-2020.......................................................... 11

Duct traverse data 2. September 2020 ..............................................................................15

Summary of the CS+HF and MF tests the 03-09-2020.........................................................16

Duct traverse data the 3. September 2020......................................................................... 19

Summary of CS+HF test the 4-09-2020............................................................................. 20

Duct traverse data the 4. September 2020......................................................................... 22

Anomalies...................................................................................................................... 22

4. High Fire net fuel consumption and burn rate calculations .......................................................23

Summary of test results .................................................................................................. 24

ADEC 18 AAC 50.077 Compliance (Fairbanks proof) ............................................................24

CSA HF1 PM report (#1) ..................................................................................................25

CSA HF1 CO, HO, EFF report (#1).....................................................................................26

CSA LF report (#2) ......................................................................................................... 27

CSA HF2 PM report (#3) ..................................................................................................28

CSA HF2 CO, HO, EFF report (#3).....................................................................................29

CSA MF report (#4)......................................................................................................... 30

CSA HF3 PM report (#5) ..................................................................................................31

CSA HF3 CO, HO, and EFF report (#5)............................................................................... 32

Weighted avg. calculation (LF#2, HF2#3, MF#4, HF3#5).....................................................33

Test facility conditions ..................................................................................................... 34

Fuel properties ............................................................................................................... 34

Summary of test fuel load properties................................................................................. 35

5. Test accomplishment .......................................................................................................... 36