Double-wall connectors must be tested and listed for use with solid-fuel burning appliances.

Single-wall connectors should be made of 24 gauge or heavier gauge steel. Do not use

galvanized connector; it cannot withstand the high-temperatures that smoke and exhaust

gases can reach, and may release toxic fumes under high heat. The connector must be 6 inches

(150mm) in diameter.

If possible, do not pass the chimney connector through a combustible wall or ceiling.

If passage through a combustible wall is unavoidable, refer to the sections on Wall

Pass- Throughs. Do not pass the connector through an attic, a closet or similar

concealed space when installing the chimney connectors.

It is important to keep the flue gases moving smoothly in the right direction. Do not vent into a

large void at this location; rather form one continuous section all the way up. Use mild bends

(e.g. 45º vs. 90º) rather than sharp angles where a change of direction is required. All parts of

the venting must be accessible for cleaning purposes.

In horizontal runs of chimney, maintain a distance of 18 inches from the ceiling. Keep it as

short and direct as possible, with no more than two 90 degree turns. Slope horizontal runs of

connector upward 1/4 inch per foot (20 mm per metre) going from the stove toward the chimney.

The recommended maximum length of a horizontal run is 3 feet (1 metre), and the total length

should be no longer than 8 feet (2.5 metres).

Information on assembling and installing connectors is provided by the manufacturer’s

instructions exactly as you assemble the connector and attach it to the stove and chimney.

Be sure the installed stove and chimney connector are correct distances from near

by combustible materials. See the clearance paragraph page 8.

1.3 Flue Connection

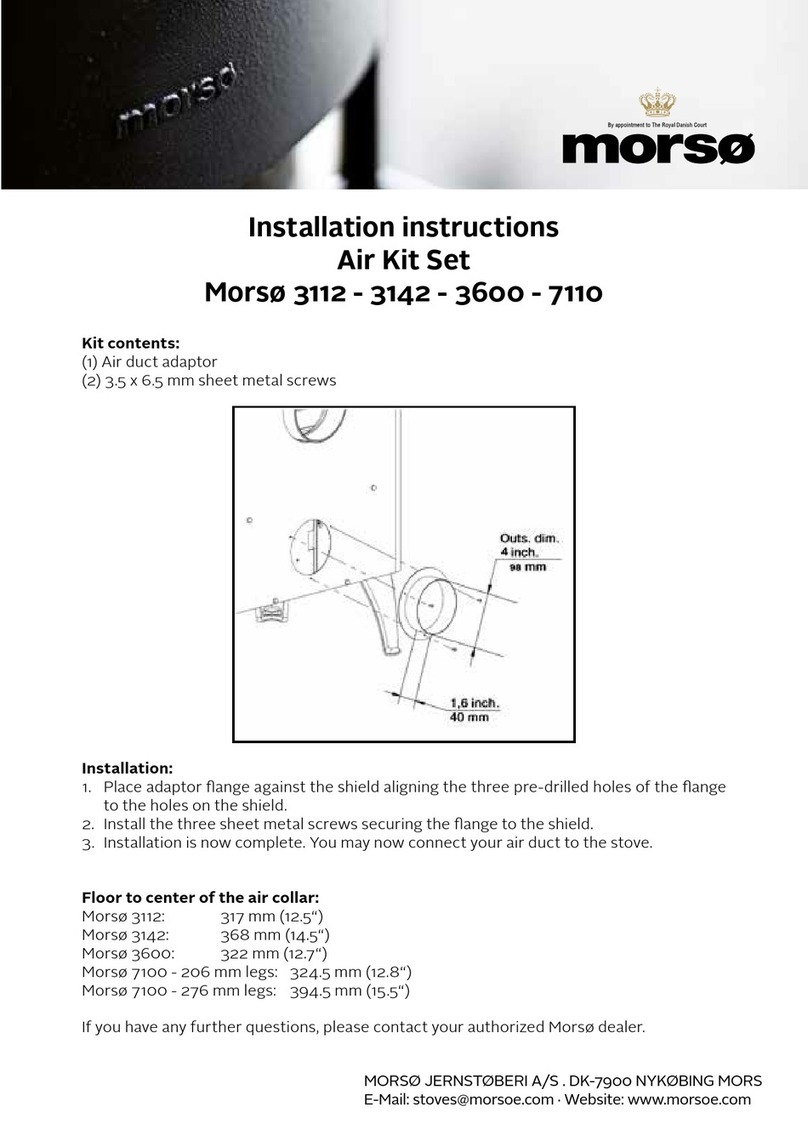

The stove is supplied from the factory with a flue collar fitted to the top plate and a round blanking

plate blocking off the rear flue exit (behind the rear shield plate).

The flue collar is from the factory prepared for fitting the enlosed 6 inche adapter.

Use a 24 MSG black or blue chimney connector or listed double wall chimney connector. Refer

to local codes and the chimney manufacturer’s instructions for precautions required for passing

a chimney through a combustible wall or ceiling. Remember to secure the chimney connector

with a minimum of three screws to the product and to each adjoining section.

The collar can be fitted to the rear outlet. Simply knock out the round panel on the rear heat

shield plate to reveal the cast iron plate. Untwist the blanking plate and the flue collar and swap

their positions. Re-secure by pushing down and tighten the enclosed screws.

Position the stove and connect to the flue system.

Wear gloves and protective eyewear when drilling, cutting or joining sections of

chimney connector

1.4 Connection to the existing chimney

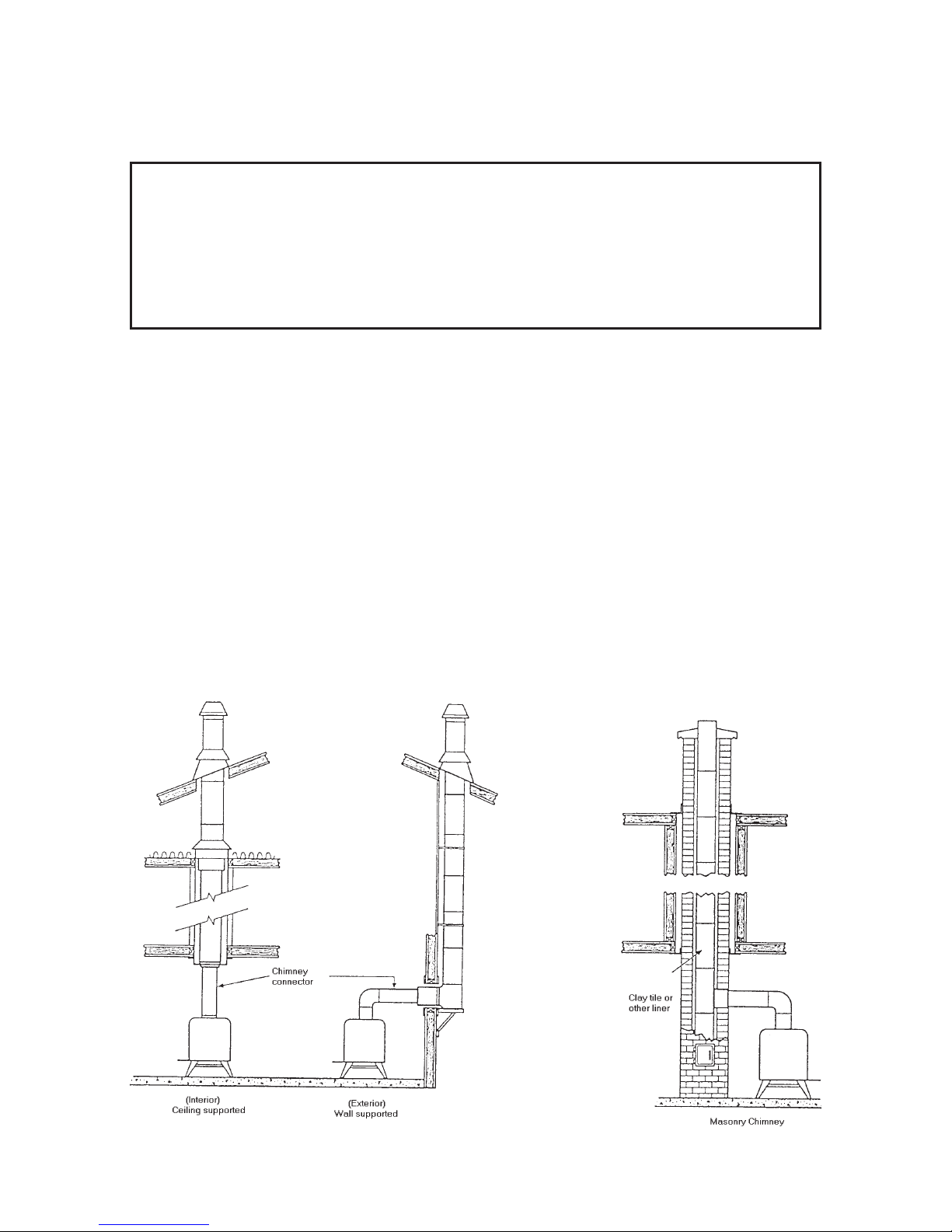

A Chimney connector is the double-wall or single-wall pipe that connects the stove to the

chimney. The chimney itself is the masonry or prefabricated structure that encloses the flue.

Chimney connectors are used only to connect the stove to the chimney.