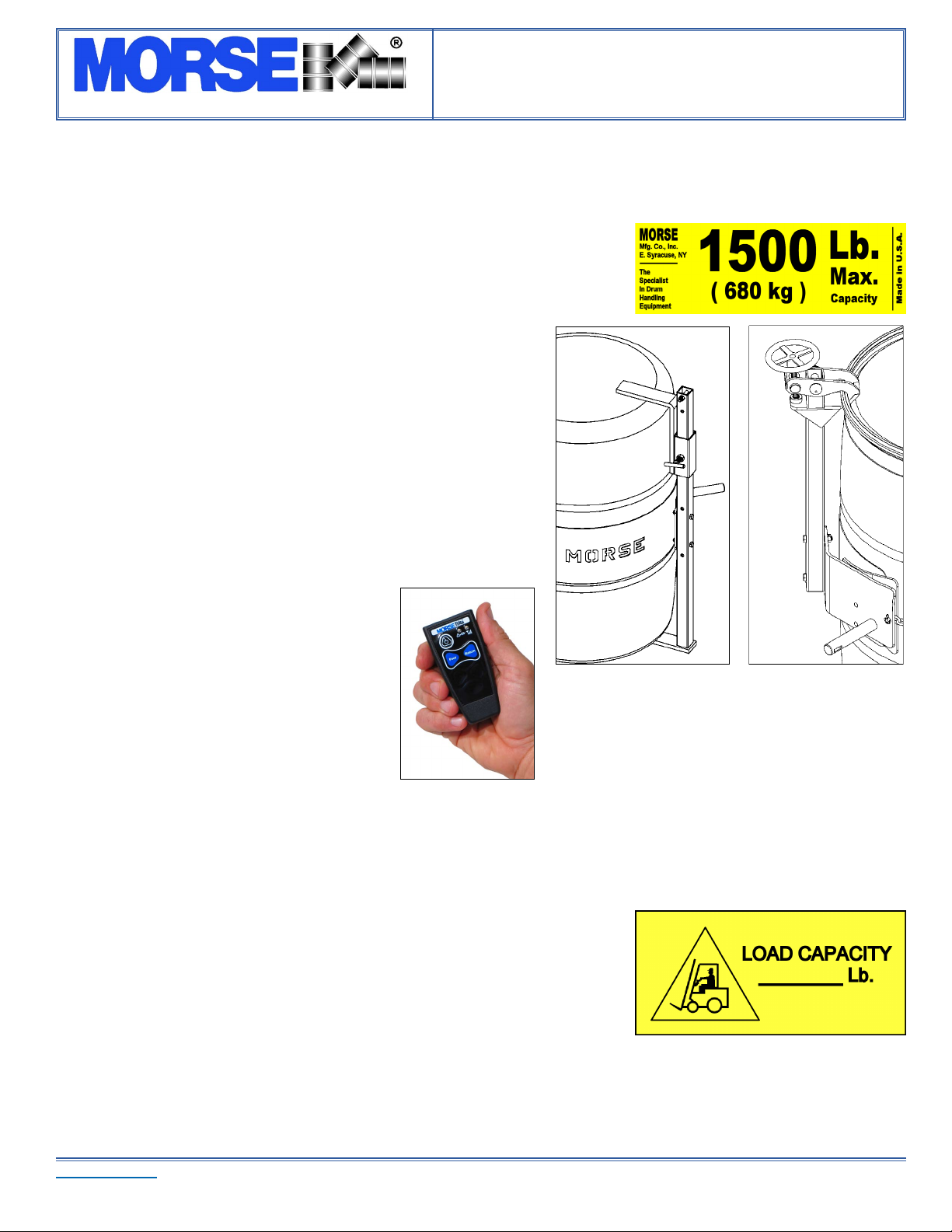

The Specialist In Drum Handling Equipment

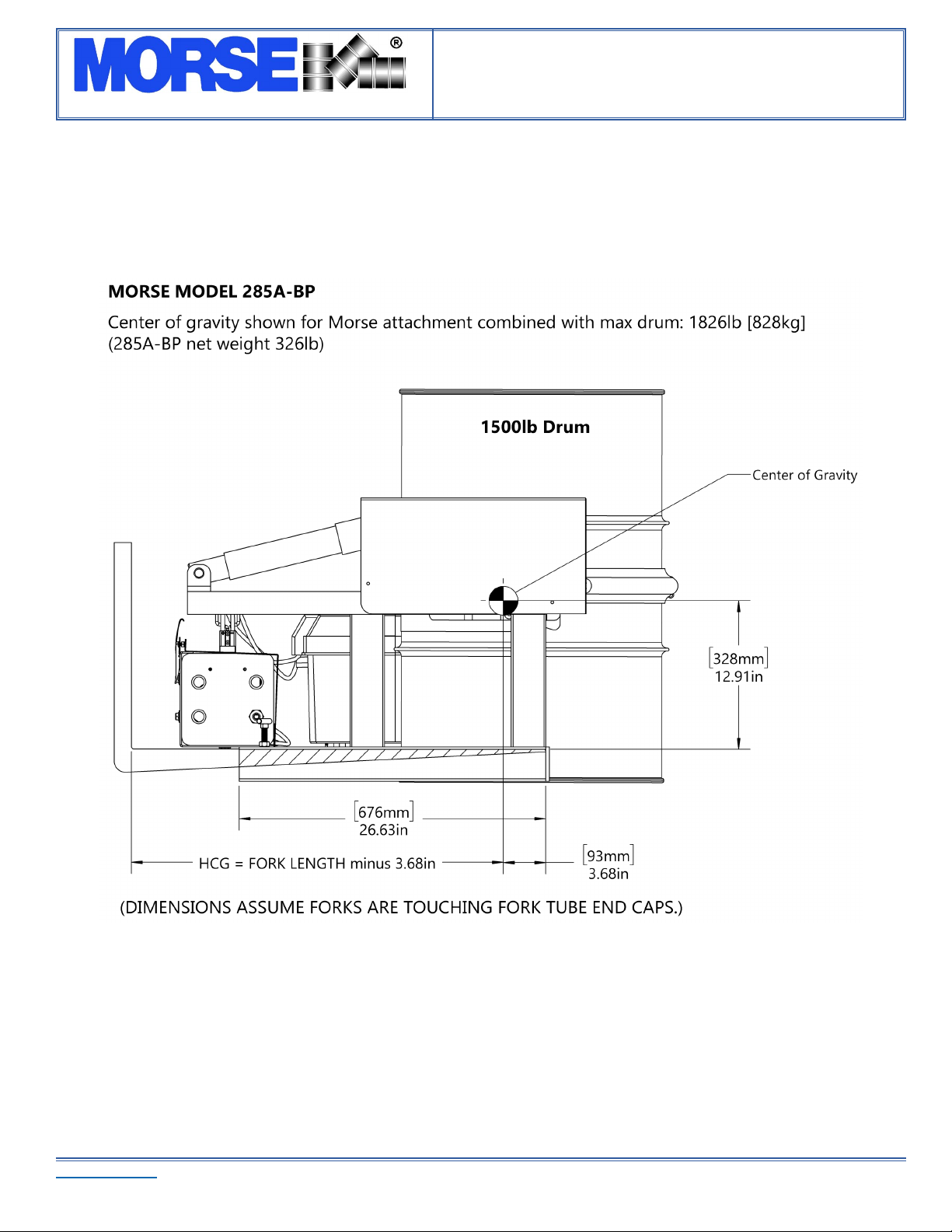

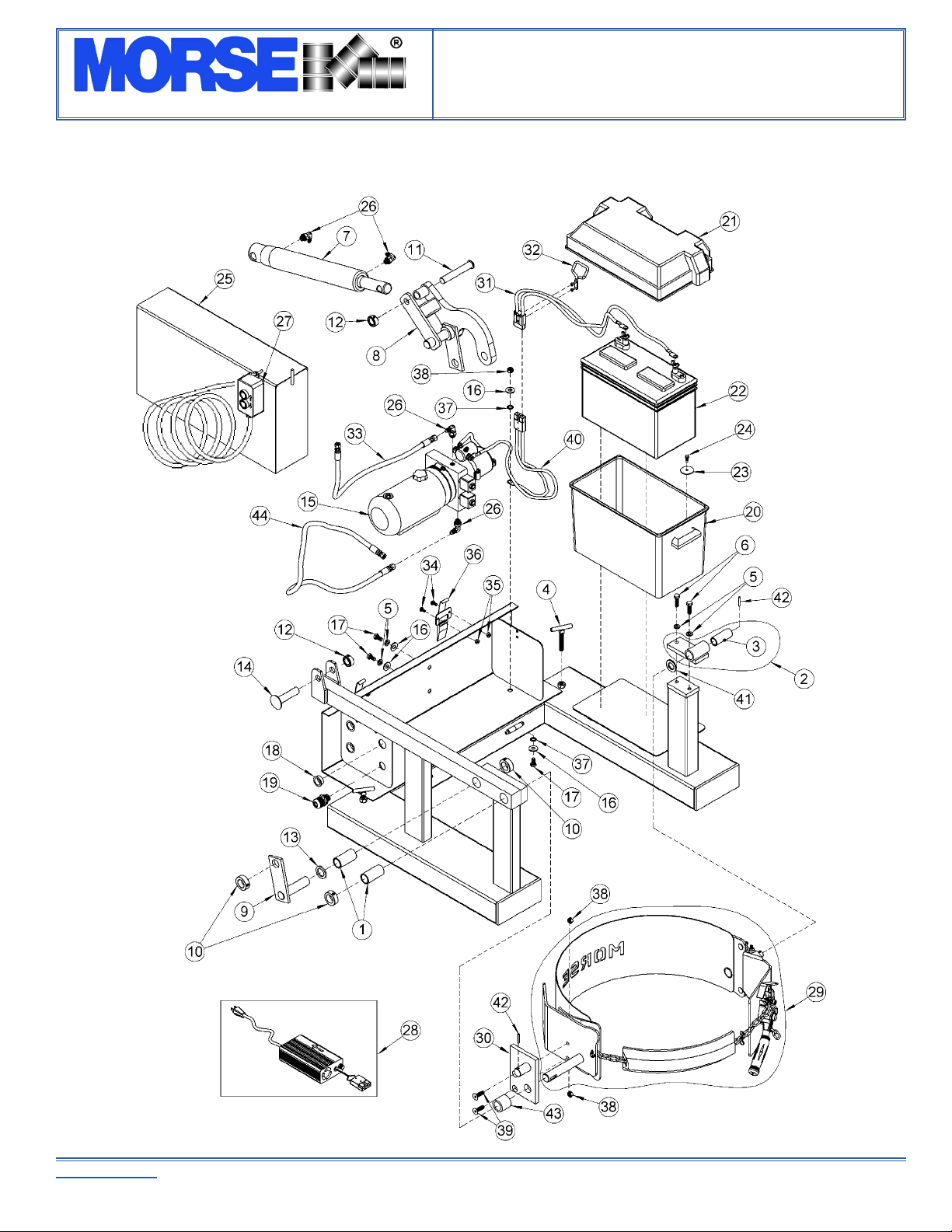

Model 285A-BP

Battery-Powered Forklift-Karrier

Operator’s Manual for Morse Battery-Powered Forklift-Karrier Model 285A-BP

Serial Number 0413 to 0617 (MMYY)

morsedrum.com

Copyright 2018 - Morse Mfg. Co., Inc. Form PL285A-BP (0413-0617) (Updated 2 Oct, 2018 1:37 PM) 6

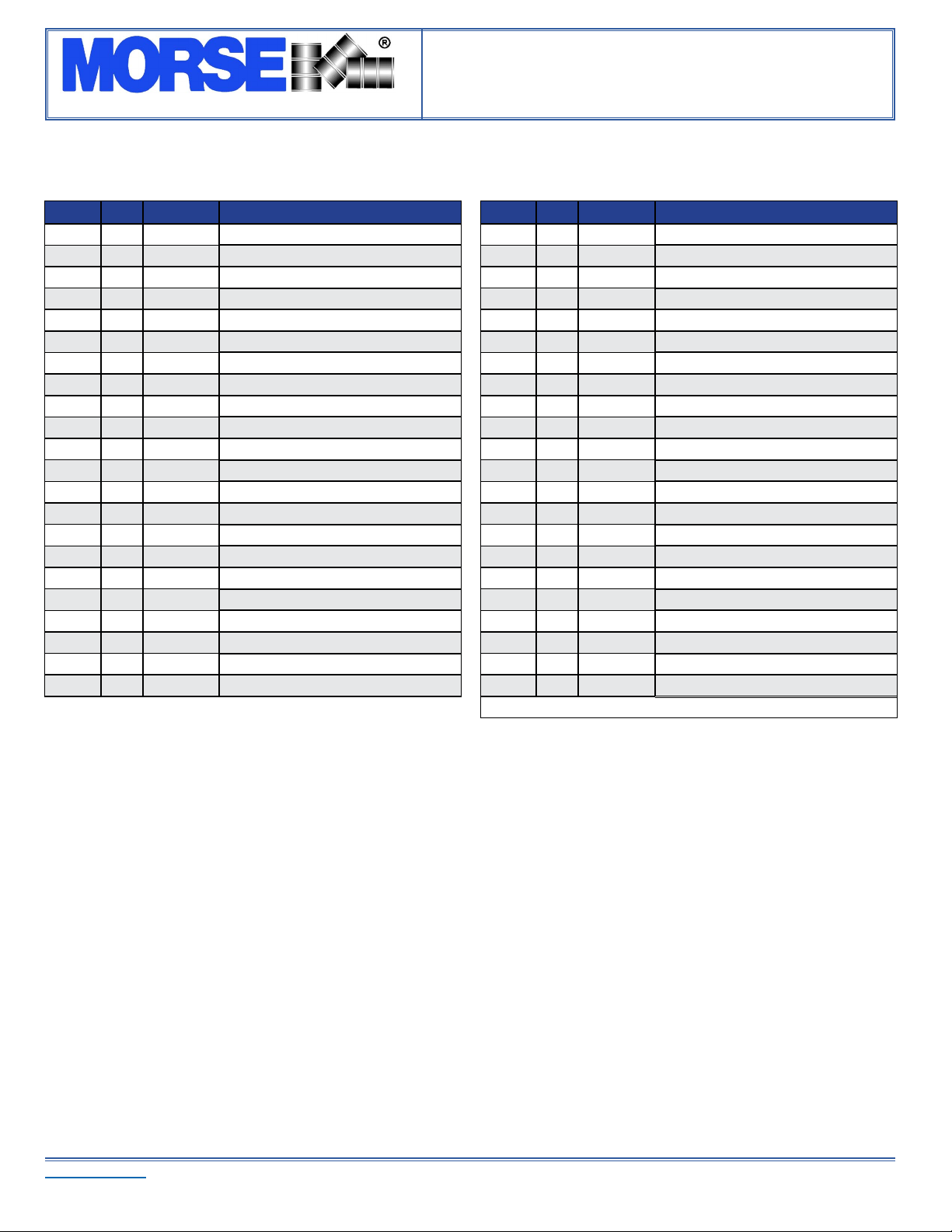

ITEM # QTY. PART # DESCRIPTION

1 * 2 18-P BEARING,1”IDX2-1/2”

2 1 3849B-P BEARING ASM, SLIDING IDLER

3 * 1 19-P BEARING,3/4”IDX2-1/2”

4 2 58-P SET SCREW, LOCK TEE, 285

5 4 1474-P WASHER, 3/8 SPLIT LOCK

6 2 535-P HHCS,3/8-16X1-1/4GR5

7 1 5522-P CYLINDER,2X10,SAEADJCLEV

8 1 1281-P POWER LINK WELD, A-BP

9 1 2500-P DRAG LINK WELD, A-BP

10 3 16-P COLLAR,1”ID

11 1 2506-P PIN WELD, CYL, 285A-BP

12 2 15-P COLLAR,3/4”ID

13 1 29-P SPACER,SPURGEAR.15”

14 1 704-P AXLE,3/4”,USEWITHPUSH-ON

15 1 M3551-P HYDPOWERPACK,12VDC,BP

16 4 1166-P WASHER,3/8USS1”OD

17 3 1657-P HHCS,3/8-16X3/4GR2

18 3 5212-P GROMMET, 1-1/2 OD, RUBBER

19 1 3682-P STRAIN RELIEF, 285A-BP

20 1 1729-P BOTTOM,BATTERYBOX,400

21 1 1728-P TOP,BATTERYBOX,400,285A-BP

22 1 388-P BATTERY,12VDC

ITEM # QTY. PART # DESCRIPTION

23 4 4168-P WASHER, 7/32, 1-1/2 OD, FENDER

24 8 193-P SCREW,12-14X3/43PTTEK

25 1 4814-P LINKAGE GUARD WELD, 285A-BP

26 4 3610-P HYD FIT, MALE ELBOW, SAE

27 1 4605-P PENDANT ASM, WIRED, 20’ A-BP

28 1 391-P CHARGER12V50HZ60HZ100-240V

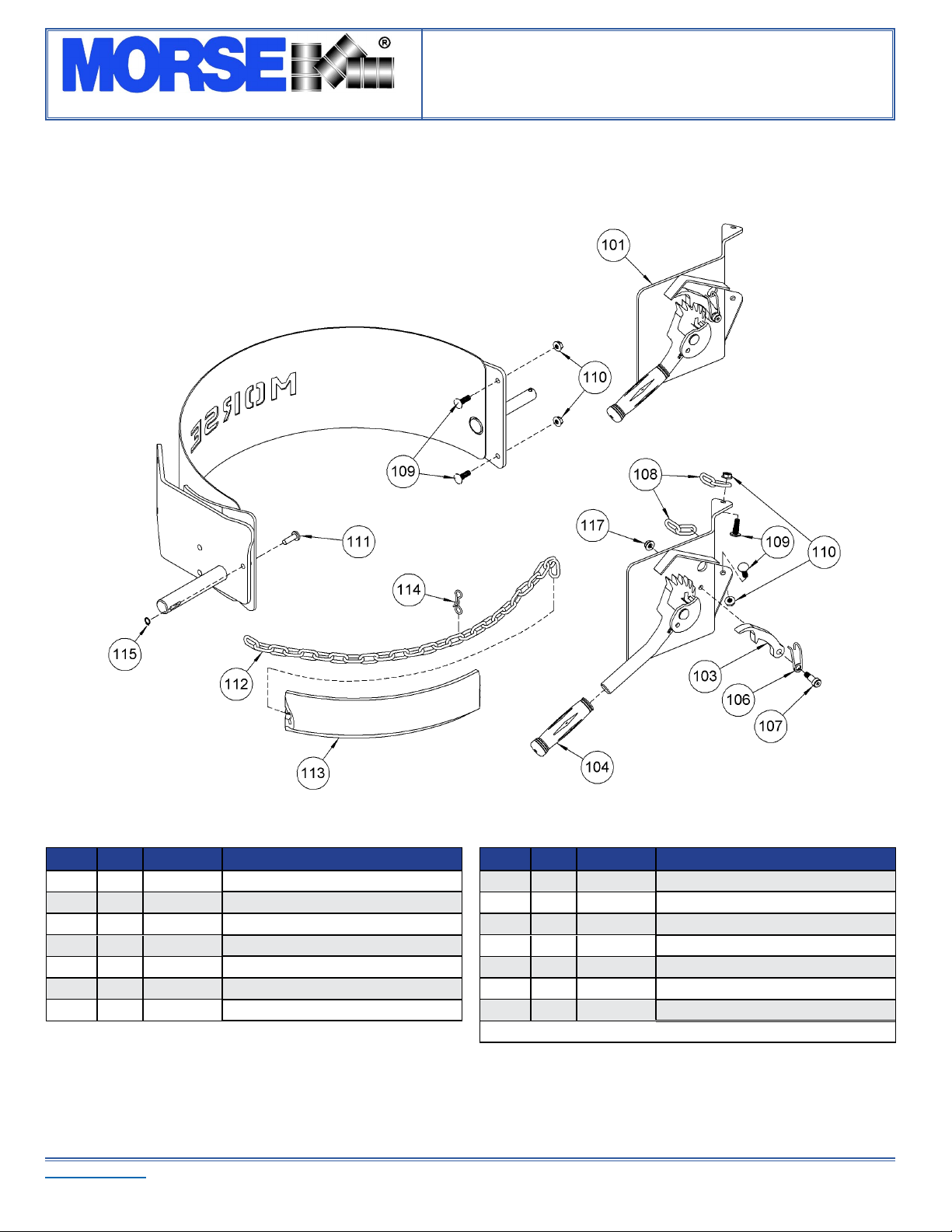

29 1 5000-P SADDLE ASM, MORCINCH, MOR

30 1 4911-P PLATE WELD, BOLT ON, A-BP

31 1 4913-P HARNESS, BATTERY CABLE, 28/20

32 1 4820-P HANDLE, BATTERY CONNECT

33 1 2466A-P HYDHOSEASM,35”285A-BP

34 4 1517-P SCREW,1/4-20X5/8PANHEAD

35 4 1518-P NUT, 1/4-20 NYLON LOCK

36 2 4770-P LATCH, SPRING, 305-CAGE, A-BP

37 2 1739-P WASHER 3/8 INTERNAL TOOTH LOCK

38 3 1169-P NUT,3/8-16REVHEXLOCK

39 2 4927-P SHCS,3/8-16X1-1/4FH

40 1 4914-P HARNESS, PUMP CABLE, 18/24

41 1 55-P WASHER, 3/4 SAE FL 1-1/2 OD

42 2 64-P ROLLPIN,3/16X1-1/4

43 1 4372-P SPACER,HDDRIVESHAFT1.4”

44 1 2467A-P HYDHOSEASM,40”285A-BP

* Recommended spare parts