morsedrum.com

Copyright 2008 - Morse Mfg. Co., Inc. Form PL285XGR (0108-1209) (Updated June 12, 2012 4:25 PM) 6

The Specialist In Drum Handling Equipment

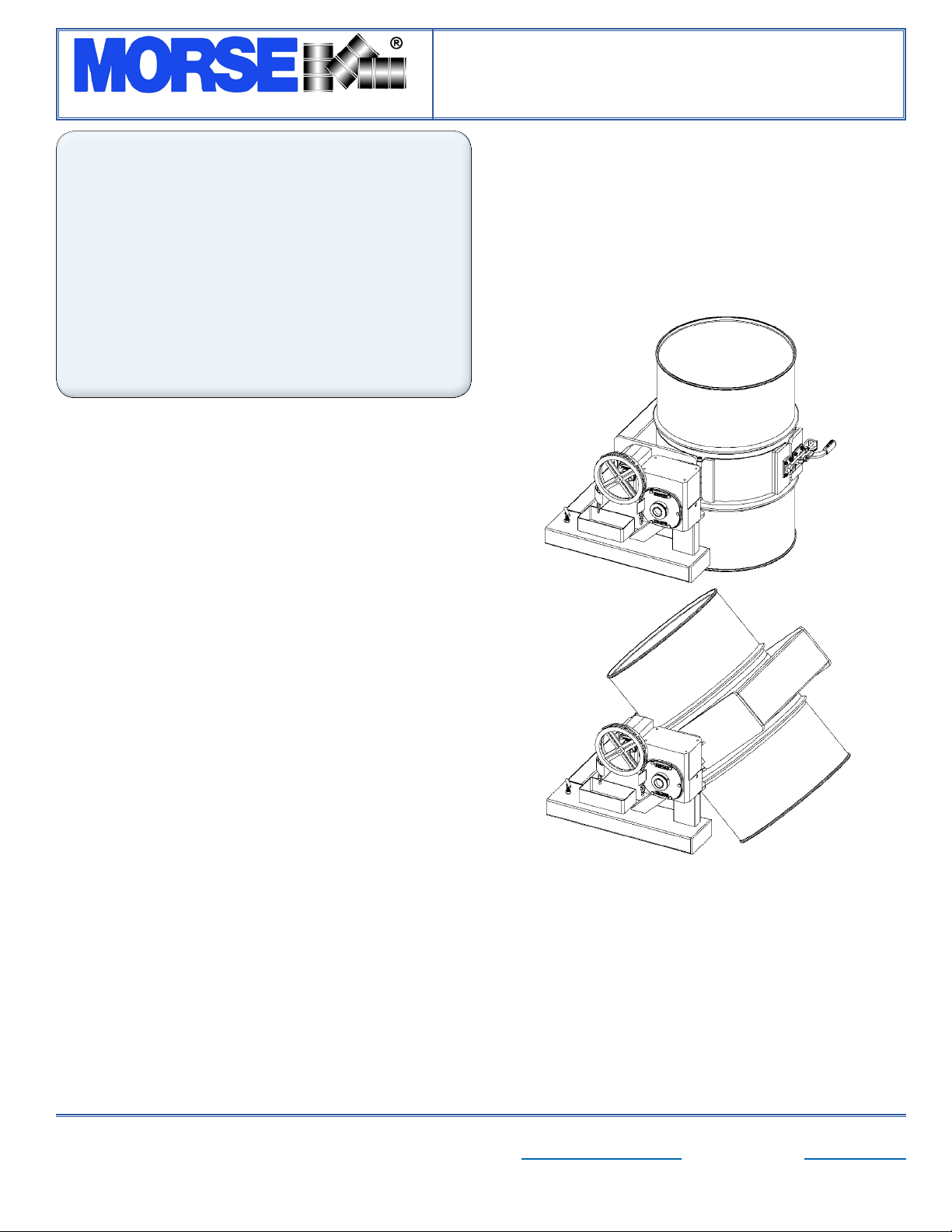

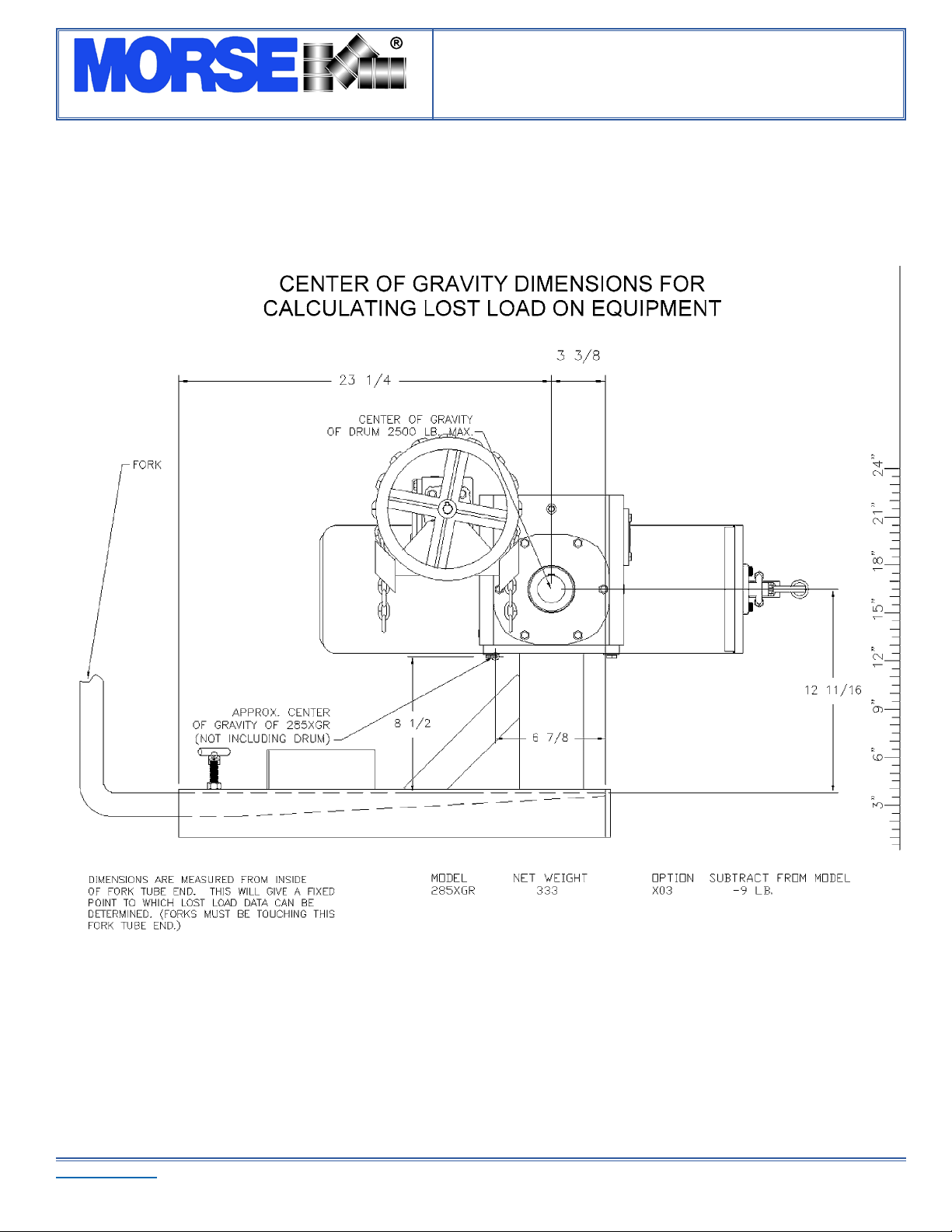

MODEL 285XGR

Extra Heavy-Duty Forklift-Karrier

Operator’s Manual for

Morse Extra Heavy-Duty Forklift-Karrier with 2500 Lb. Capacity - Model 285XGR

Serial Number 0108 to 1209 (MMYY)

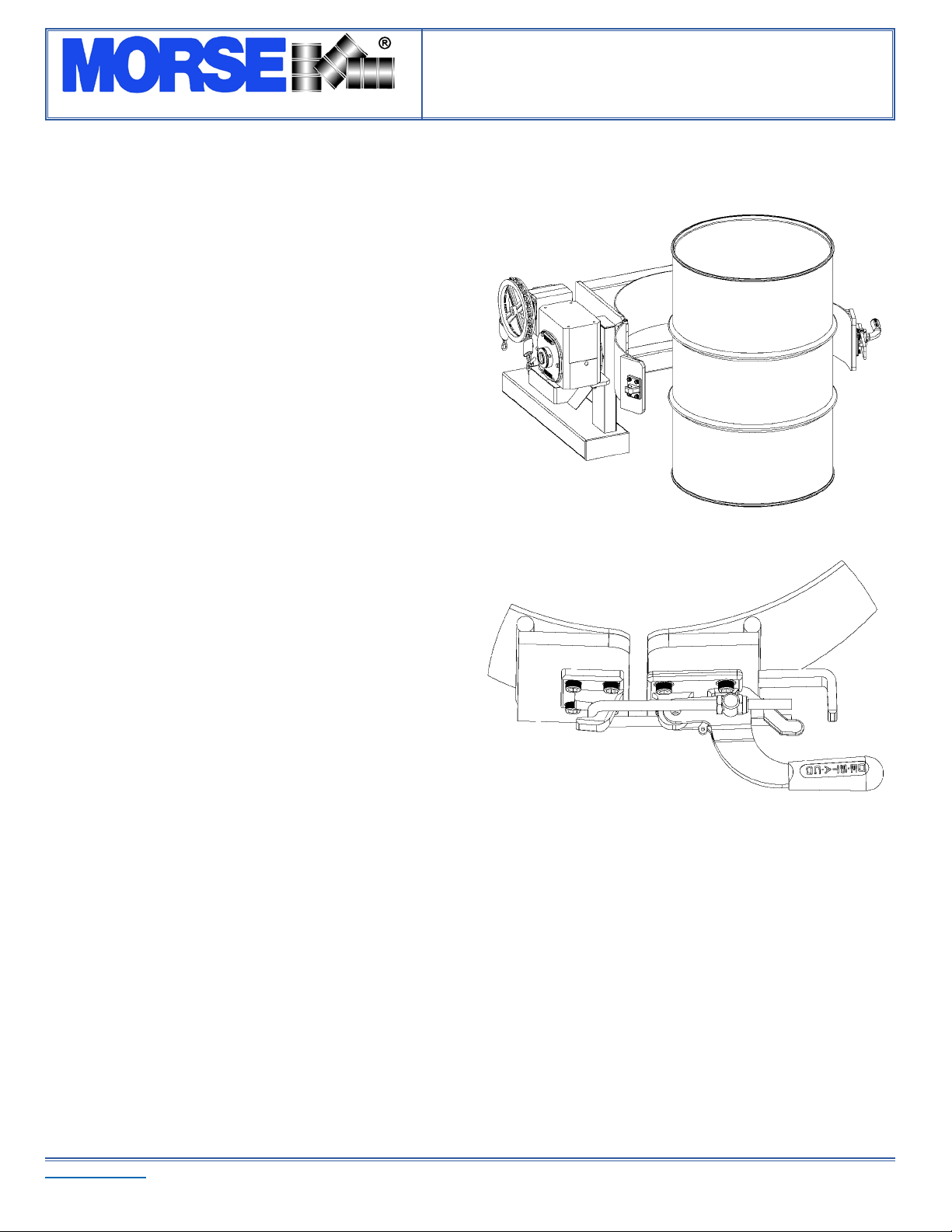

ITEM QTY PART # DESCRIPTION

1 2 1000-P SET SCREW, 1/4 - 20 X 1/4

2 1 1322-P POCKET CHAIN WHEEL, 5/8 BORE

3 1 1304-P GUIDE, POCKET CHAIN WHEEL

4 1 1324-P BUSHING, 5/8 ID X 1” OD

5 1 3-285-P PULL CHAIN, POCKET, 20’ LENGTH

6 1 1326-P KEY, SQUARE, 3/16 X 1”

7 1 603-P SPEED REDUCER, 2 STAGE, 285GR

8 2 1166-P WASHER, 3/8 USS 1” OD

9 2 1502-P HHCS, 7/16-14 X 1-1/4 GR5

10 1 595-P IDLER BEARING ASM, 285GR

11 2 1474-P WASHER, 3/8 SPLIT LOCK

12 2 535-P HHCS, 3/8-16 X 1-1/4 GR5

13 2 58-P SET SCREW, LOCK TEE, 285

14 2 540-P WASHER, 1-1/2 SAE FL 3” OD

15 * 2 560-P BEARING, 1-1/2” ID X 2”, GR

ITEM QTY PART # DESCRIPTION

16 1 570-P COLLAR, 1-1/2” ID

17 1 525-P KEY, WOODRUFF, SIZE F, ASA1211

18 2 810-P NUT, LOCK, 1/2-13 REV HEX

19 2 3592-P SHCS, 1/2-13 X 7-1/2

20 1 4516-P FRONT BAND WELD, CLAMP, XGR

21 1 4515-P FRONT BAND WELD, CATCH, XGR

22 1 3067-P CATCH, 375-R TOGGLE, CAMLOCK

23 8 22-P SHCS, 3/8-24 X 5/8

24 1 4190-P U-BOLT, 7”, 375-R CLAMP

25 1 3601-P RELEASE LEVER, 2984-P

26 * 1 4187-P TOGGLE CLAMP, W/ U BOLT

27 1 4511-P SADDLE ASM, XGR, 3PC, 2500LB

28 1 4512-P SADDLE WELD, XGR, 2500 LB. (NOT SOLD

SEPERATELY)

29 1 590-P BASE FRAME 285GR W/ BRG

* Recommended spare parts