Operator’s Manual for MORSE 185-HD HEAVY-DUTY KONTROL-KARRIERS

Serial Number 0793 to ____ (MMYY)

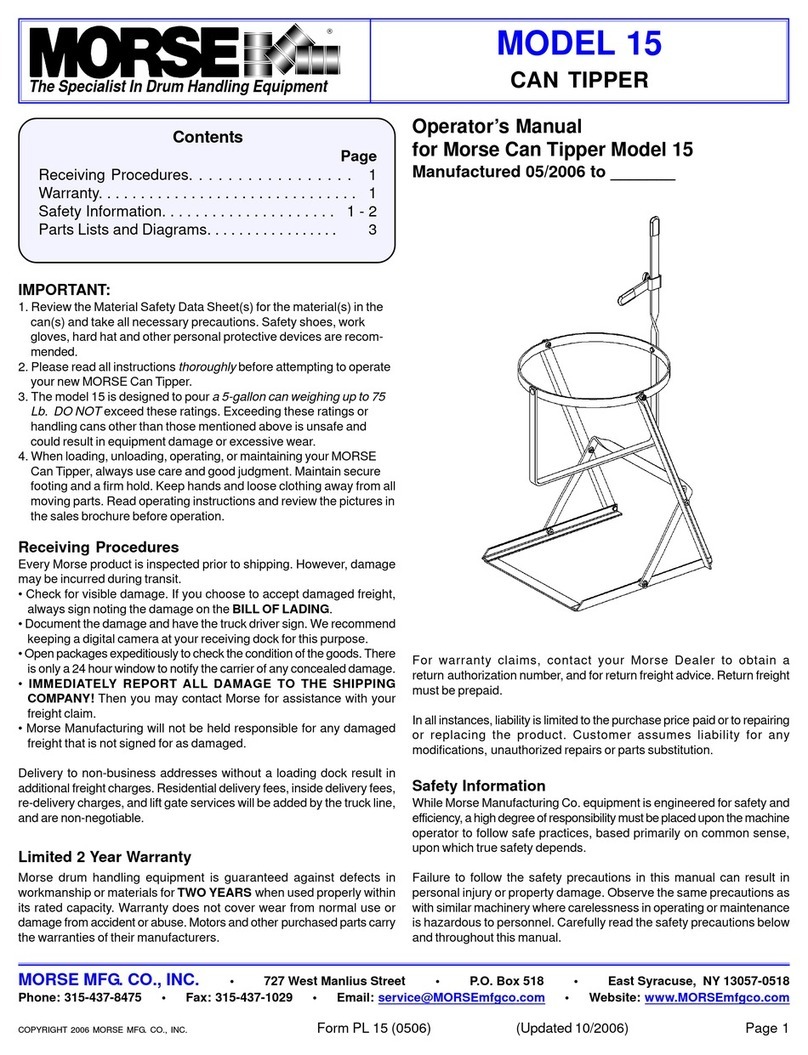

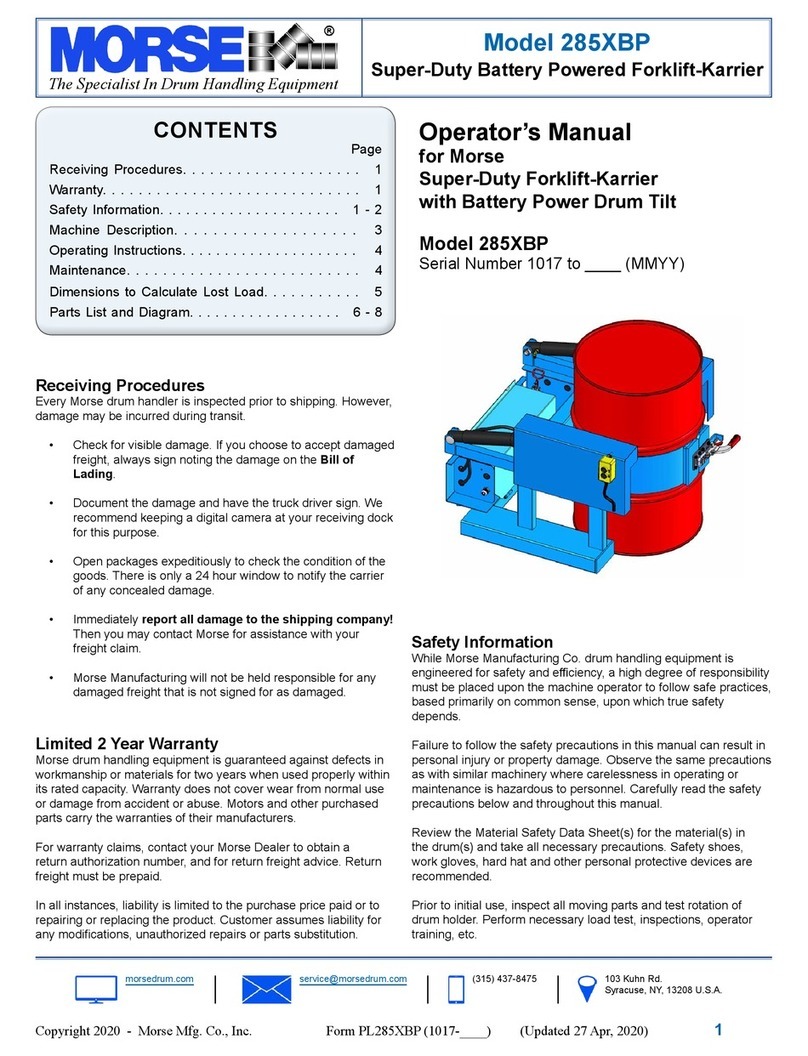

185A-HD for 55 gallon standard steel drums (22 ½” diameter)

185G-HD for 55 gallon standard steel drums (22 ½” diameter)

185B-HD for 30 gallon standard steel drums (19” diameter)

185C-HD for steel or fibre drums (21-23” diameter)

185D-HD for steel or fibre drums (19-20½” diameter)

A. IMPORTANT:

1. Review the Material Safety Data Sheet(s) for the material(s) in the drum(s) and take all necessary precautions. Safety shoes,

work gloves, hard hat and other personal protective devices are recommended.

2. Please read all instructions thoroughly before attempting to operate your new MORSE drum handler.

3. The 185-HD series has a maximum capacity rating of 1500 Lb. FULL drum, and 800 Lb. HALF-FULL drum, and is intended

for lifting, moving and pouring drums of size and type noted above. DO NOT exceed these ratings as an unsafe condition

may result which could cause damage or excessive wear, or make the unit awkward to handle.

4. When loading, unloading, operating, or maintaining your MORSE drum handler, always use care and good judgment, have

good footing and a firm hold. Keep hands and loose clothing, etc. away from all moving parts. Never allow anyone to be

below any part of a raised drum handler or drum. Read operating instructions and review the pictures in the sales brochure

before operation.

5. The 185-HD is a “Group 1 - Structural and Mechanical” Below-the-Hook Lifting Device which is covered by the American

National Standard ANSI/ASME B30.20. The user should comply with all aspects of this standard.

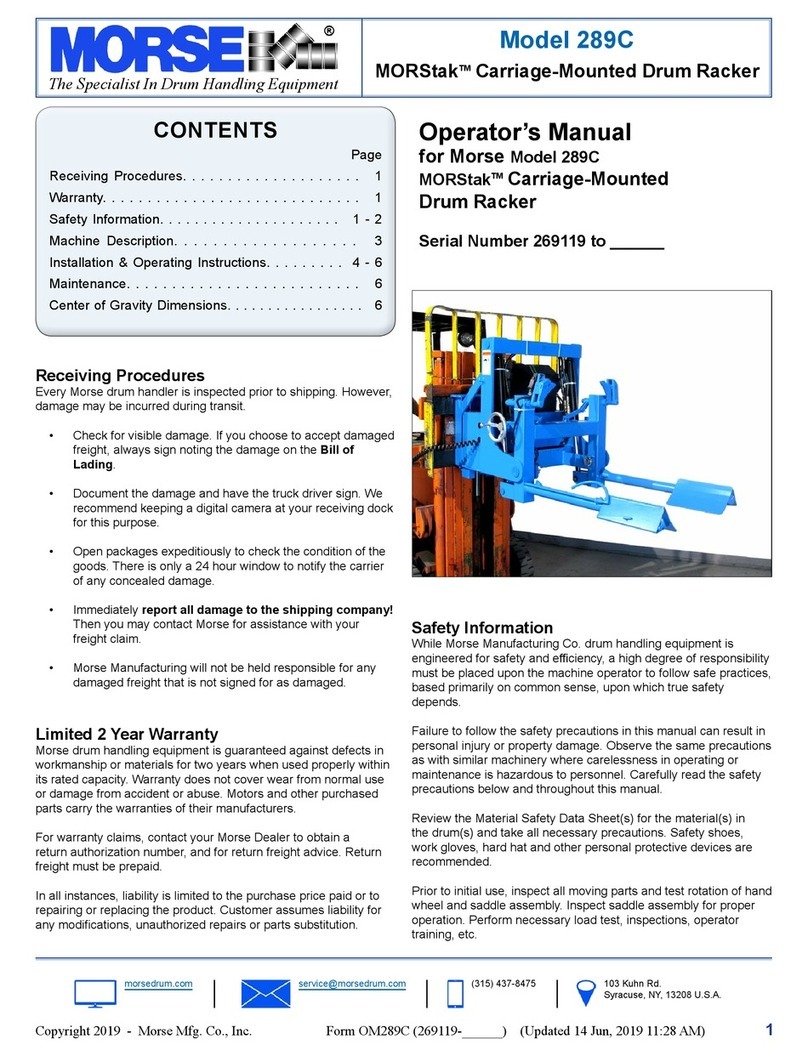

B. OPERATING INSTRUCTIONS:

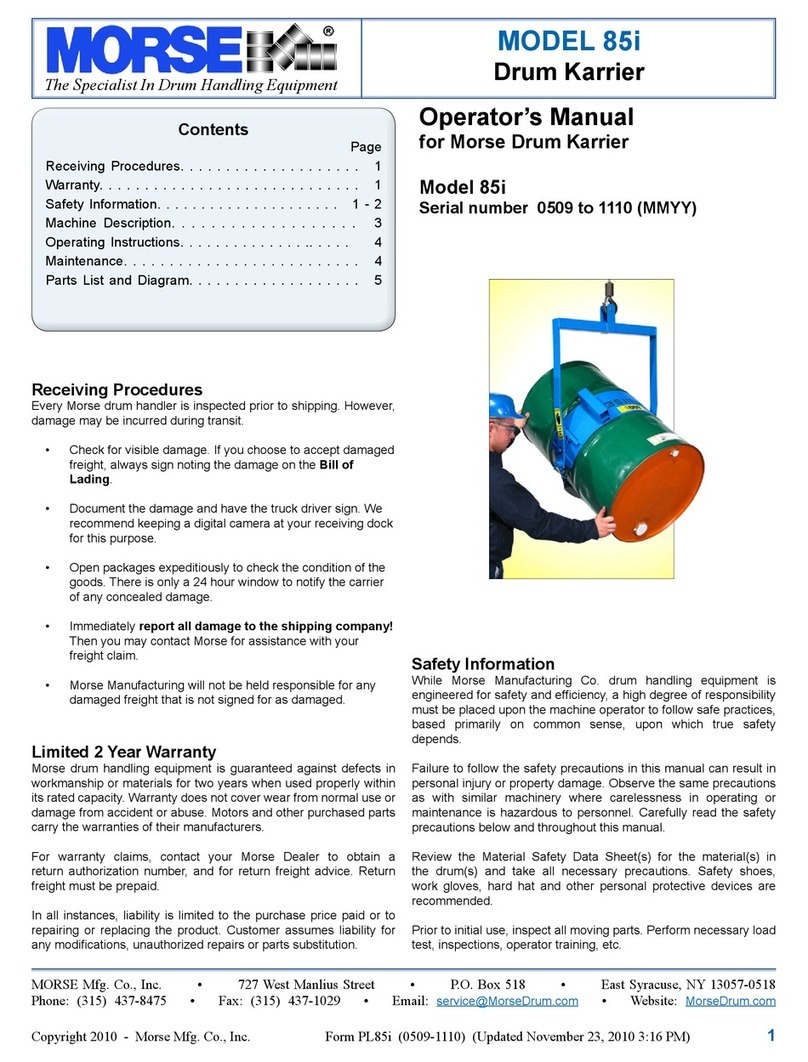

1. Start with Kontrol-Karrier on the floor. Lower hoist and engage hoist hook to off-center lift point. Empty Kontrol-Karrier will

hang plumb from off-center lift point.

2. Raise hoist to lift Kontrol-Karrier clear of floor and transport it next to the drum.

3. Suspend Kontrol-Karrier at a height which aligns drum saddle with center of drum.

4. With binder (item 28 or 29) chain hanging freely, push Kontrol-Karrier against drum so that saddle will encircle drum. (On the

Model 185G-HD, pull the linch pin (item 46), open the toggle clamp, and swing both hinge bands to the open position.)

5. Drape the binder across the face of the drum and engage a link in notch in hub of ratchet (item 37).

See assembly detail on page 3. (On the Model 185G-HD, close the two hinged bands around the drum, latch the toggle

clamp, and insert the linch pin.)

6. Lock drum in place by turning ratchet to tighten chain.

7. Move hoist hook to lift point which is centered over the drum.

8. Raise hoist and position drum at pouring station.

9. To pour drum: Pull on control chain (item 3) rotating drum to angle required for emptying. For best control of drum pouring

angle, pay out one side of the loop while pulling in the other, thus being able to hold back the drum rotation after the load

shifts.

10. After emptying, rotate drum back to vertical position and lower hoist to return empty drum.

11. To remove drum: Pull ratchet handle to relieve pressure on ratchet teeth. Lift pawl handle (item 33) to release teeth

engagement and rotate ratchet to loosen chain and allow its removal from notch.

CAUTION: DO NOT allow drum to impact on floor, ground, or dumping station, etc. or there may be damage.

CAUTION: DO NOT exceed weight capacity of 1500 Lb. for FULL drum, 800 Lb. for HALF-FULL drum.

C. MAINTENANCE:

1. Lubricate gear teeth and roller chain.

2. Oil ratchet, pawl, saddle hinge and other moving parts periodically.

3. Periodically inspect all moving parts, framework, and contact areas for signs of wear, fatigue, or loosening. Tighten, adjust or

replace parts as necessary to prevent failure and maintain proper function.

COPYRIGHT 2005 MORSE MFG. CO., INC. Form PL 185HD (0793-____) (Updated 05/2005) Page 1

MORSE MFG. CO., INC. • 727 West Manlius Street • P.O. Box 518 • East Syracuse, NY 13057-0518

Phone:

315-437-8475

•

Fax:

315-437-1029

•

Email:

[email protected] • Website: www.MORSEmfgco.com185HD SERIES

HEAVY-DUTY KONTROL-KARRIERS

The Specialist In Drum Handling Equipment