The Specialist In Drum Handling Equipment

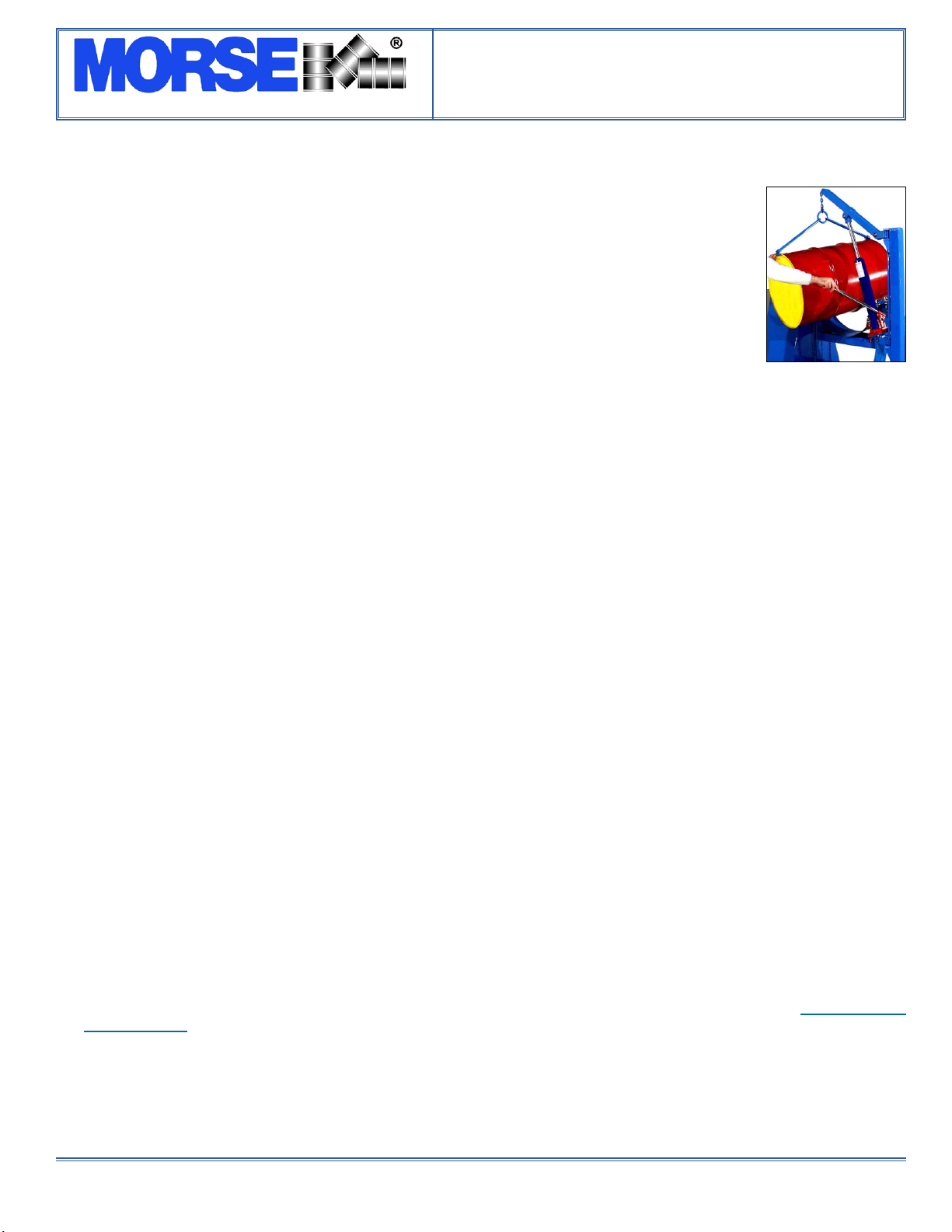

2-300 Series

Endover Rotator (Discontinued)

Operator’s Manual for Morse 2-300 Series End-Over-End Drum Rotators

Serial Number 239790 to 275508

morsedrum.com

Copyright 2015 - Morse Mfg. Co., Inc. Form PL2-300 (239790-275508) (Updated 14 Jun, 2019) 4

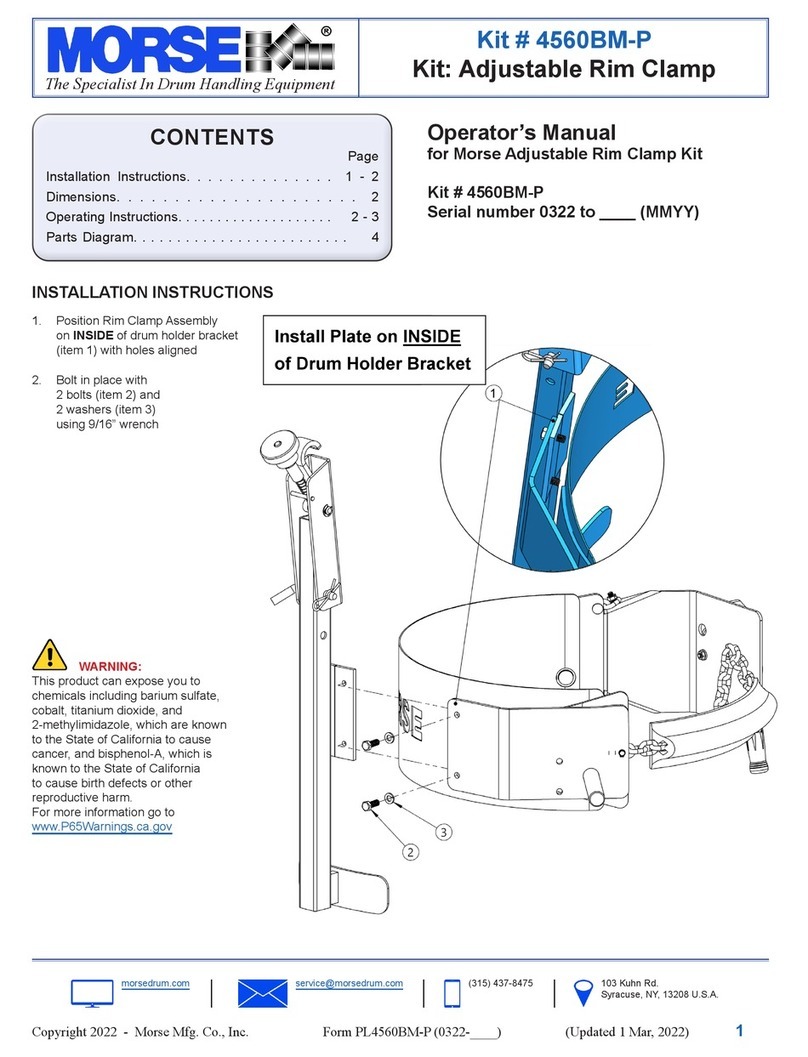

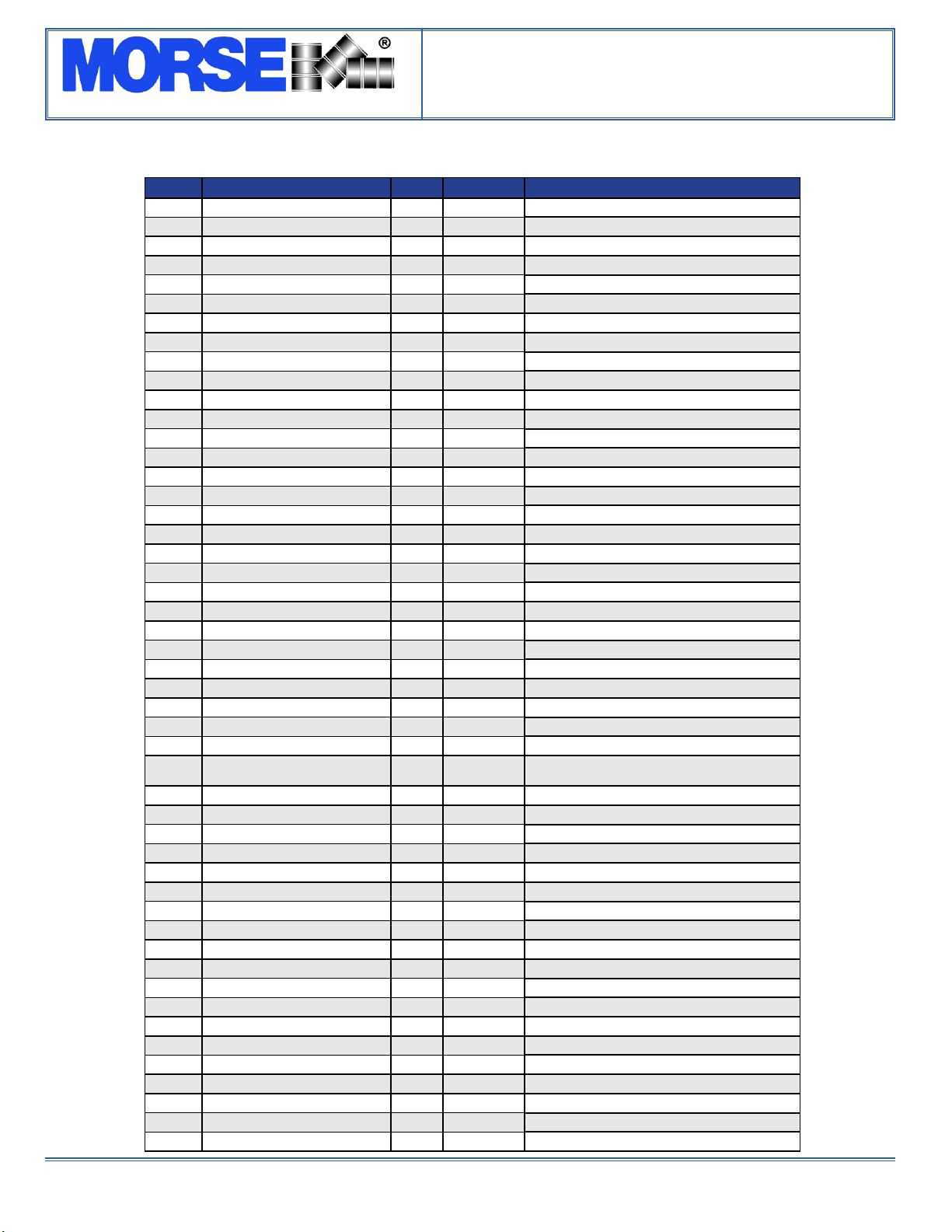

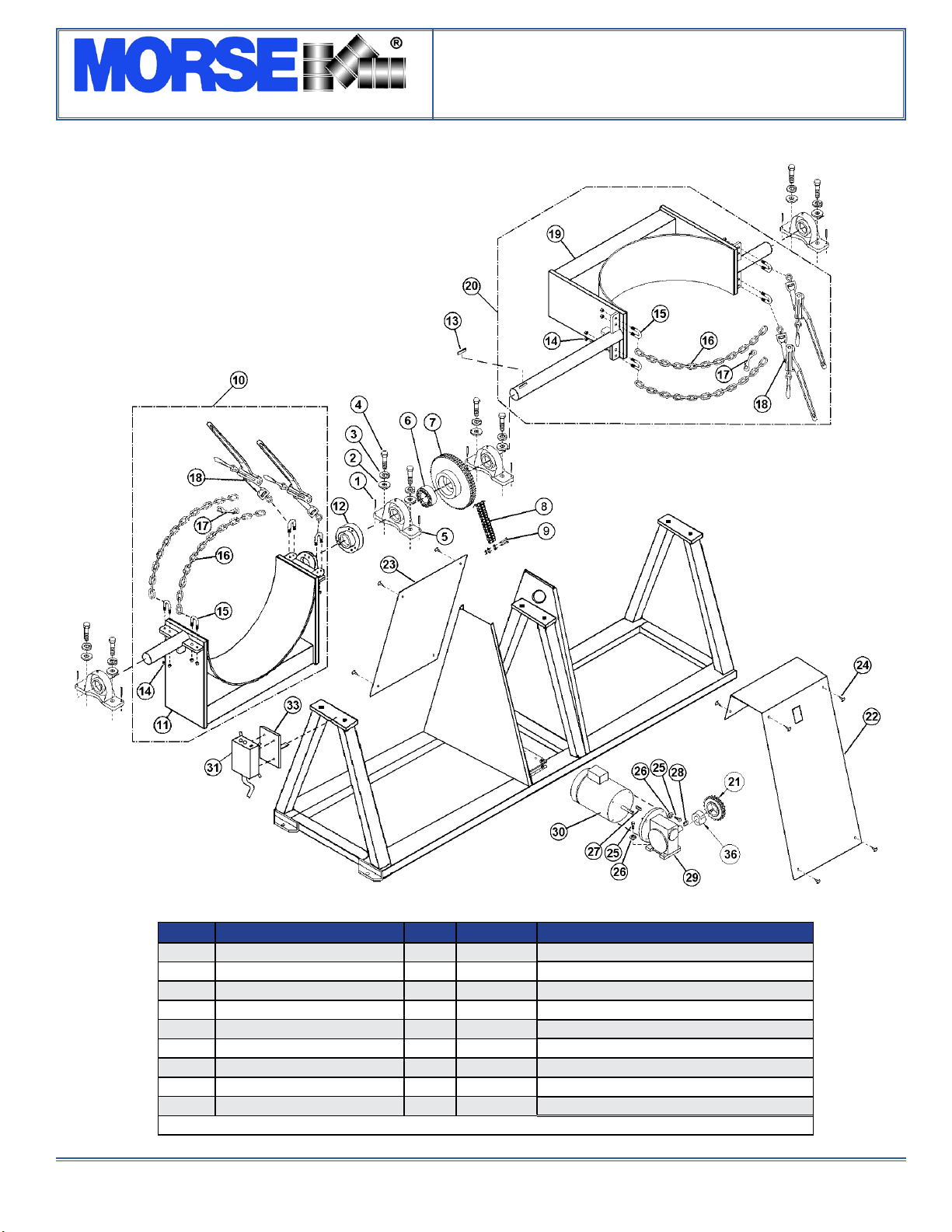

ITEM MODEL SUFFIX QTY PART # DESCRIPTION

1 * 8 64-P ROLL PIN, 3/16 X 1-1/4

2 8 807-P WASHER, 1/2 USS 1-3/8 OD

3 8 1644-P WASHER, 1/2 SPLIT LOCK

4 8 1168-P HHCS, 1/2-13 X 2 GR2

5 * 4 312-P BEARING, 1-1/2” PILLOW BLOCK

6 1 2348-P HUB, 1-1/2 KEYLESS, FRICTIONAL

7 * 1 2353-P 60T SPROCKET #40D, KEYLESS

8 * 1 317-72-P CHAIN, ROLLER, #40D 145 PITCH

9 * 1 796-P LINK, MASTER, #40D CHAIN

10 1 2376-P SADDLE ASM, HUB, 2-300

11 2375-P SADDLE WELD, HUB, 2-300 (NOT SOLD SEPARATELY)

12 1 1224-P QD BUSHING, SK X 1-1/2” BORE

13 1 525-P KEY, WOODRUFF, SIZE F, ASA1211

14 16 1169-P NUT, LOCK, 3/8-16 REV HEX

15 * 8 314-P U-BOLT, 3/8-16, GR, 300

16 * 4 180-P CHAIN, CINCH, 3/16 ALLOY 33 LK

17 2 575-P SNAP HOOK, GR, 300

18 * 4 315-P LOAD BINDER

19 SADDLE WELD (NOT SOLD SEPARATELY)

20 1 2371-P SADDLE ASM, DRIVE, 2-300

21 * 1 3127-P SPROCKET #40D 20T, TAPER 310

22 1 1065-P COVER, DRIVE, FRONT, 300

23 1 1066-P COVER, DRIVE, BACK, 300

24 16 193-P SCREW, TEK, 12-14 X 3/4” 3 PT

25 8 1572-P HHCS, 3/8-16 X 1 GR2

26 8 1474-P WASHER, 3/8 SPLIT LOCK

27 * 1 1638-P KEY, SQUARE, 3/16 X 1-3/8”

28 * 1 1646-P KEY, SQUARE, 1/4 X 1-1/2”

29 1 4701-P SPEED REDUCER, 2-300, 50:1

29 3-220-50, 3-380-50, 3-440-50, E3-220-50,

E3-380-50, E3-440-50, E3-575 1 4701-50-P SPEED REDUCER, 2-300 50:1 50HZ

30 1-115, 1-230 1 320-1-2P MOTOR, 1-1/2HP, 1PH, 56C, TEFC

30 1-220-50 1 320-1-50-2P MOTOR, 1-1/2HP, 1PH, 50HZ

30 3-230, 3-460 1 320-3-2P MOTOR, 1-1/2HP, 3PH, 56C, TEFC

30 3-220-50, 3-380-50, 3-440-50 1 320-3-50-2P MOTOR, 1-1/2HP, 3PH, 50HZ

30 3-575 1 320-575-2P MOTOR, 1-1/2HP, 575V, 56C

30 E1-115, E1-230 1 320-E1-2P MOTOR, 1-1/2HP, 1PH, 56C, EXP

30 E1-220-50 1 320-E1-50-2P MOTOR, 2HP, 3PH, EXP 50HZ

30 E3-230, E3-460 1 320-E3-2P MOTOR, 1-1/2HP, 3PH, 56C, EXP

30 E3-220-50, E3-380-50, E3-440-50 1 320-E3-50-2P MOTOR, 1-1/2HP, 3PH, 50HZ EXP

30 E3-575 1 320-E575-2P MOTOR, 1-1/2HP, 575V, EXP

30 A 1 320-A-2P MOTOR, AIR, 2+, 56C 6AM 8 VANE

31 1-115 1 1249-P CONTROL BOX, X-300-1-115

31 1-230, 1-220-50 1 1250-P CONTROL BOX, 2-300-1-230

31 3-230, 3-220-50 1 1247-P CONTROL BOX, 2-300-3-230

31 3-380-50 1 1679-P CONTROL BOX, X-300-380-50

31 3-460, 3-440-50 1 1248-P CONTROL BOX, 2-300-3-460

31 3-575 1 1251-P CONTROL BOX, 2-300-3-575

31 E1-115 1 2968-P CONTROL BOX, X-300-E1-115

31 E1-230, E1-220-50 1 2969-P CONTROL BOX, X-300-E1-230