Fm210_01b_oi_e.docx / Nov-20 Page 3 / 40

Table of Contents

Safety Instructions and Responsibility.....................................................................5

General Safety Instructions........................................................................................................ 5

Use according to the intended purpose ..................................................................................... 5

Installation ................................................................................................................................. 6

EMC Guidelines......................................................................................................................... 7

Cleaning, Maintenance and Service Notes................................................................................ 7

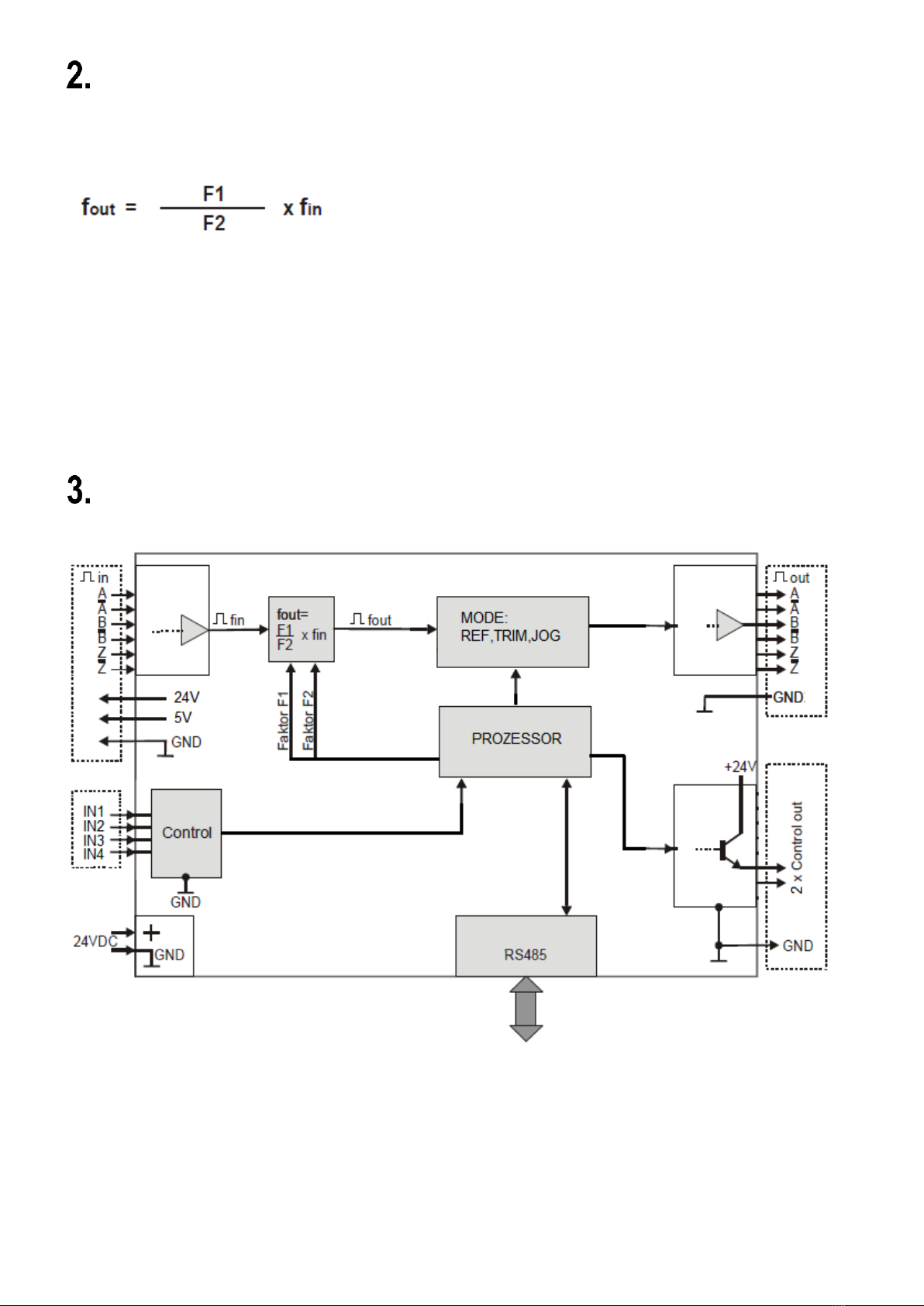

Introduction ................................................................................................................8

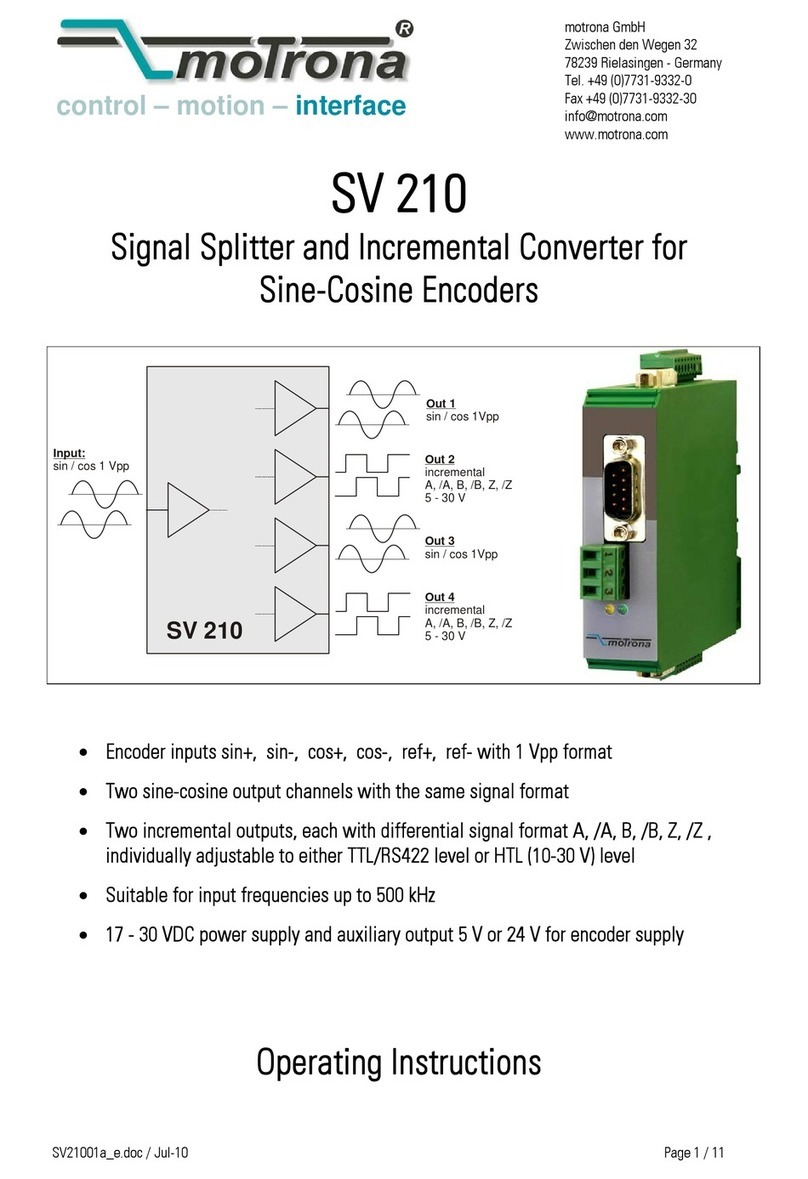

Block Diagram ............................................................................................................8

Electrical Connections...............................................................................................9

DC Input Voltage Supply ........................................................................................................... 9

Output for encoder supply 5V/24V Out ...................................................................................... 9

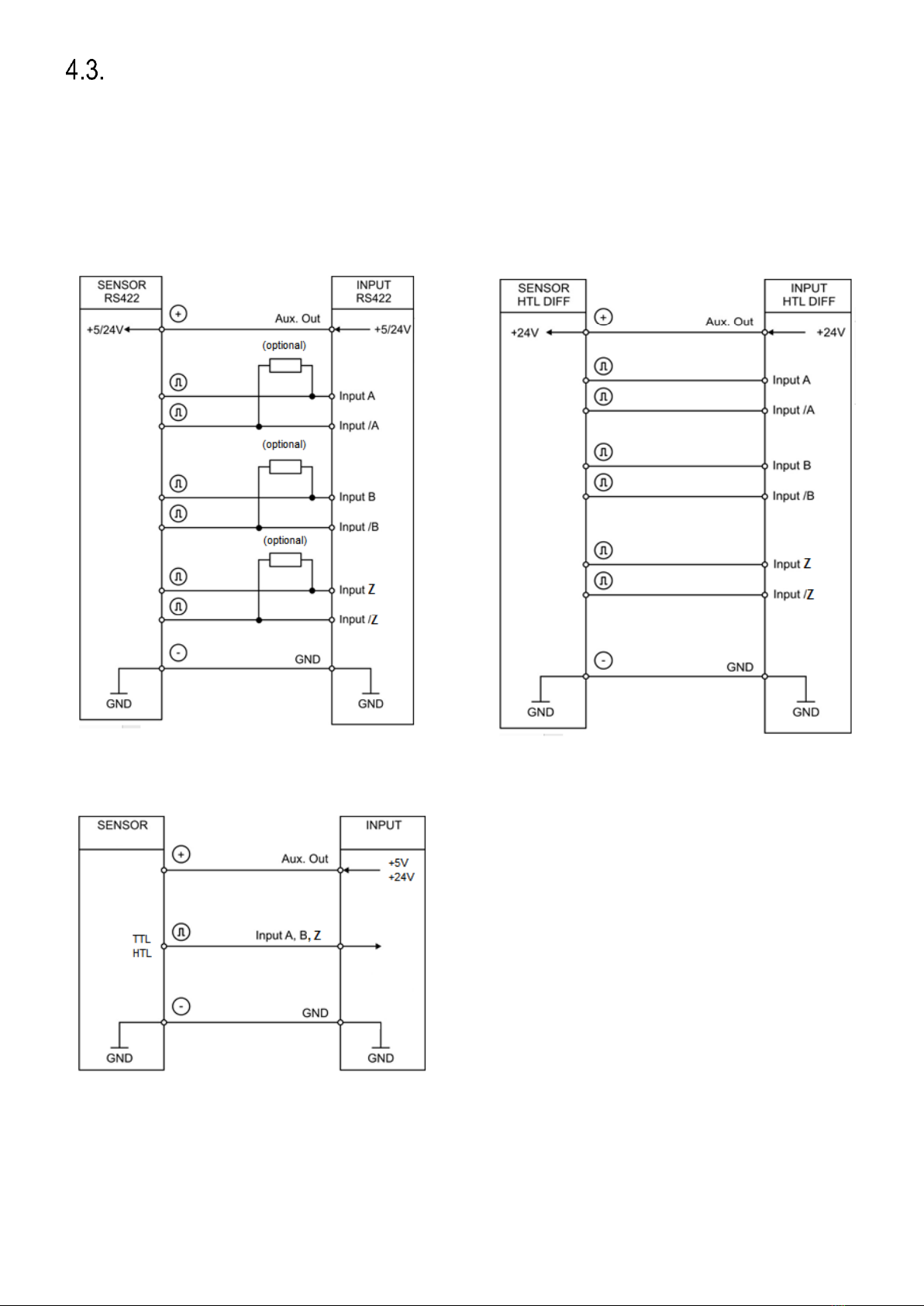

Encoder Inputs A, /A, B, /B, Z, /Z............................................................................................. 10

Control-Inputs INx.................................................................................................................... 11

Encoder Output A, /A, B, /B, Z, /Z............................................................................................ 11

Control Outputs OUTx ............................................................................................................. 11

LEDs........................................................................................................................................ 12

DIL Switch ............................................................................................................................... 12

USB ......................................................................................................................................... 12

RS-485 .................................................................................................................................... 12

Parameter..................................................................................................................13

Factor Menu............................................................................................................................. 13

Command Menu ...................................................................................................................... 13

General Menu.......................................................................................................................... 14

Input Menu............................................................................................................................... 15

Output Menu............................................................................................................................ 16

Modbus Menu.......................................................................................................................... 16

Serial Menu ............................................................................................................................. 17

Commissioning ........................................................................................................18

Setting the Encoder Mode ....................................................................................................... 18

Setting the Encoder Output...................................................................................................... 18

Setting the Factor Ratio ........................................................................................................... 18

Setting the Output Direction..................................................................................................... 18

Additional Optional Settings..................................................................................................... 19

6.5.1. Setting the Z Output Pulses............................................................................................................19

6.5.2. Setting the Serial RS-485 Interface ................................................................................................19

Input Functions ........................................................................................................20

Reset Static ............................................................................................................................. 20

Direction .................................................................................................................................. 20

Trim+/- ..................................................................................................................................... 21

Offset Edge.............................................................................................................................. 22

Reset Edge.............................................................................................................................. 22

Z Reference............................................................................................................................. 23

Inhibit....................................................................................................................................... 23

Jog........................................................................................................................................... 23

Prestop Mark ........................................................................................................................... 25

Edge Prestop........................................................................................................................... 26

Reference ................................................................................................................................ 26