Io221_01a_oi_e.docx / Jul-23 Seite 3 / 42

Inhaltsverzeichnis

Safety Instructions and Responsibility.......................................................................... 5

General Safety Instructions.............................................................................................................5

Use according to the intended purpose ..........................................................................................5

Installation .......................................................................................................................................6

EMC Guidelines ...............................................................................................................................7

Cleaning, Maintenance and Service Notes.....................................................................................7

Introduction.................................................................................................................. 8

Function diagram .............................................................................................................................9

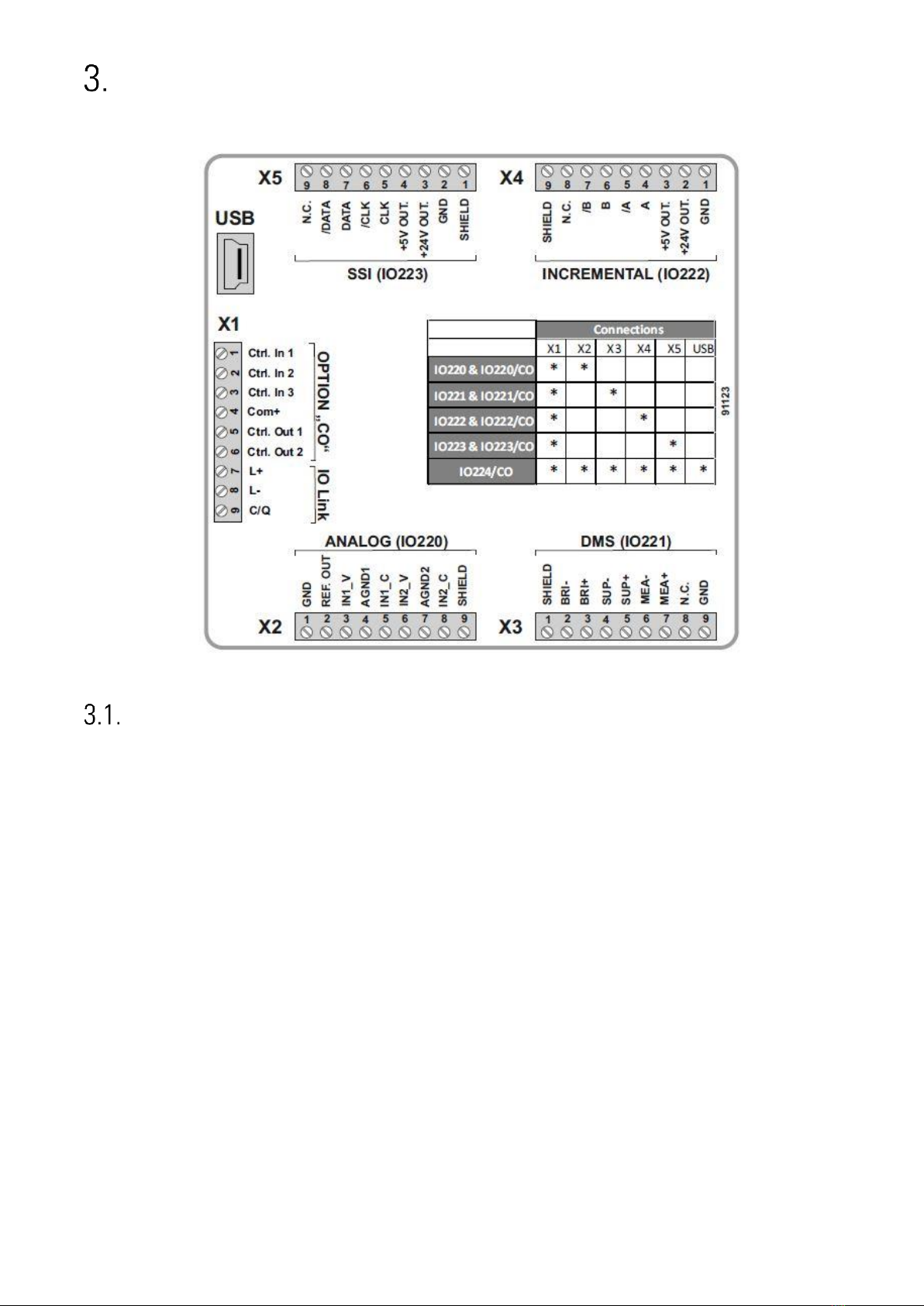

Electrical Connections................................................................................................ 10

DC Power Supply ...........................................................................................................................10

DMS Input......................................................................................................................................11

Control Inputs (only with option „CO“)..........................................................................................12

Control Outputs (only with option „CO“).......................................................................................13

IO-Link Interface.............................................................................................................................14

Usable IO Link masters.........................................................................................................................14

Communication data.............................................................................................................................14

Features ................................................................................................................................................14

Front LED...............................................................................................................................................14

Connection of the IO Link interface......................................................................................................15

Parameter data .....................................................................................................................................15

System Kommandos .............................................................................................................................18

IO-Link Process data .............................................................................................................................19

Error types.............................................................................................................................................20

Events....................................................................................................................................................21

Parameter / Overview - Menu Structure..................................................................... 22

Sensor Menu..................................................................................................................................23

Digital Input Menu.........................................................................................................................25

Digital Output Menu ......................................................................................................................26

General Menu ................................................................................................................................30

Adjustment Menu ..........................................................................................................................31

Commissioning........................................................................................................... 33

Basic setting oft he strain gauge sensor.......................................................................................33

Easiest setting ...............................................................................................................................34

Conversion to sensor units ............................................................................................................35

Digtal Input ....................................................................................................................................36

Digital Output.................................................................................................................................36

Other optional settings ..................................................................................................................36

Examination of the analog read in values............................................................................................36

Calibration of the MEA readback ..................................................................................................37

Calibration of analog input BRI / DMS..........................................................................................37

Input stage calibration..........................................................................................................................37

Calibration of the input stage and the DMS sensor............................................................................38

Monitor codes for calibration...............................................................................................................38

Attachment ................................................................................................................ 39

Parameter / serial codes................................................................................................................39