Table of Contents

Safety Instructions and Responsibility ................................................ 4

General Safety Instructions ....................................................................... 4

Use according to the intended purpose ......................................................... 4

Installation........................................................................................... 5

Cleaning, Maintenance and Service Notes ................................................ 5

Compatibility Hint ....................................................................... 6

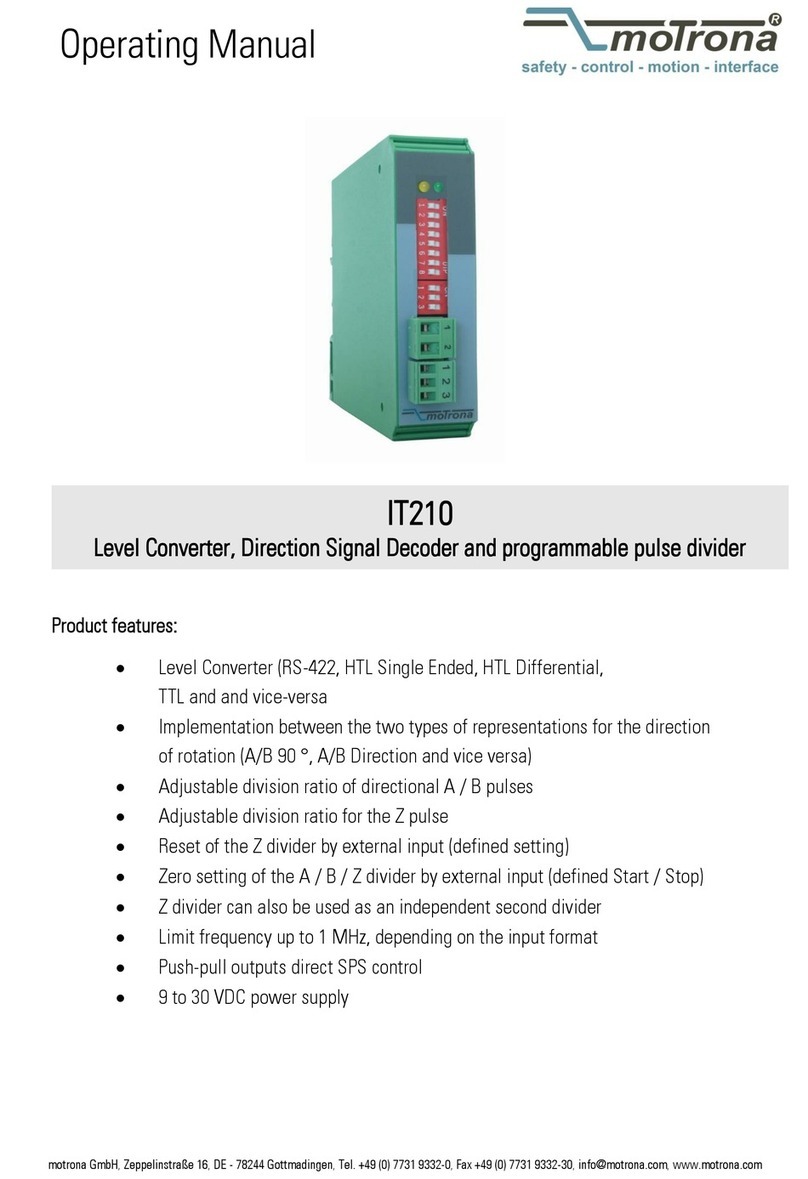

Introduction .............................................................................. 7

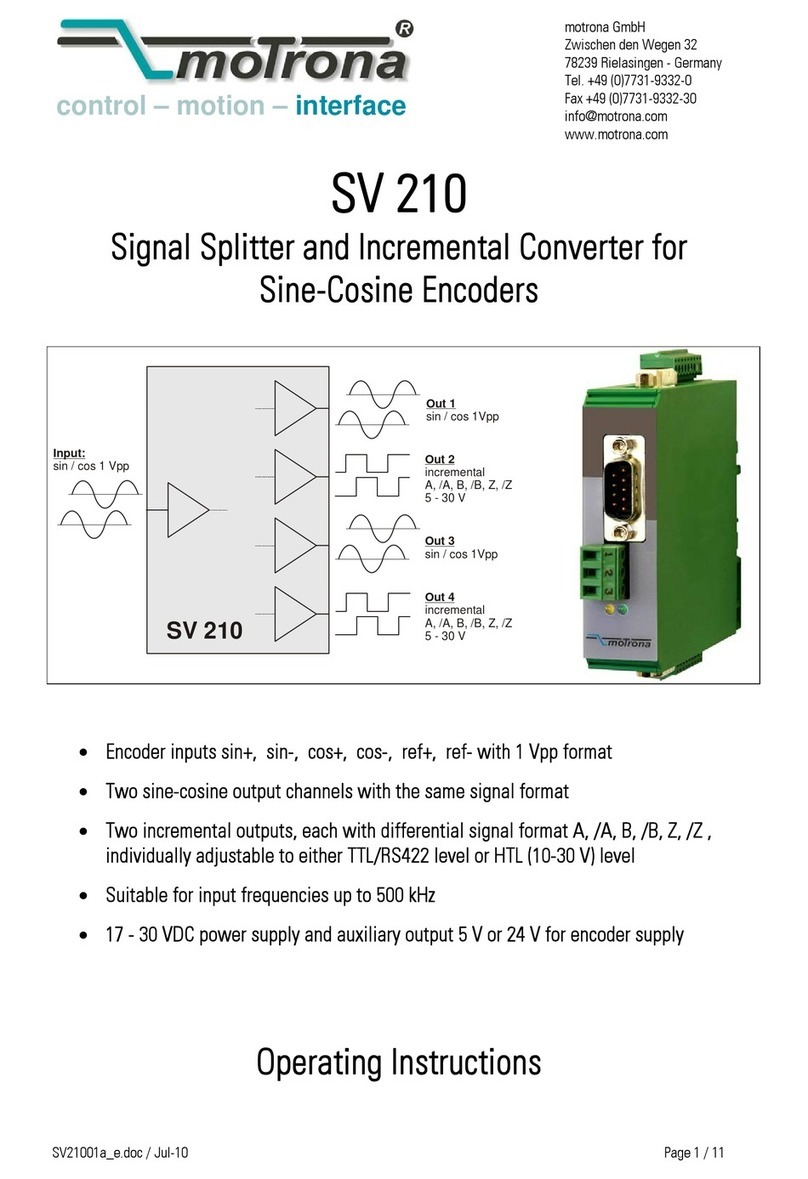

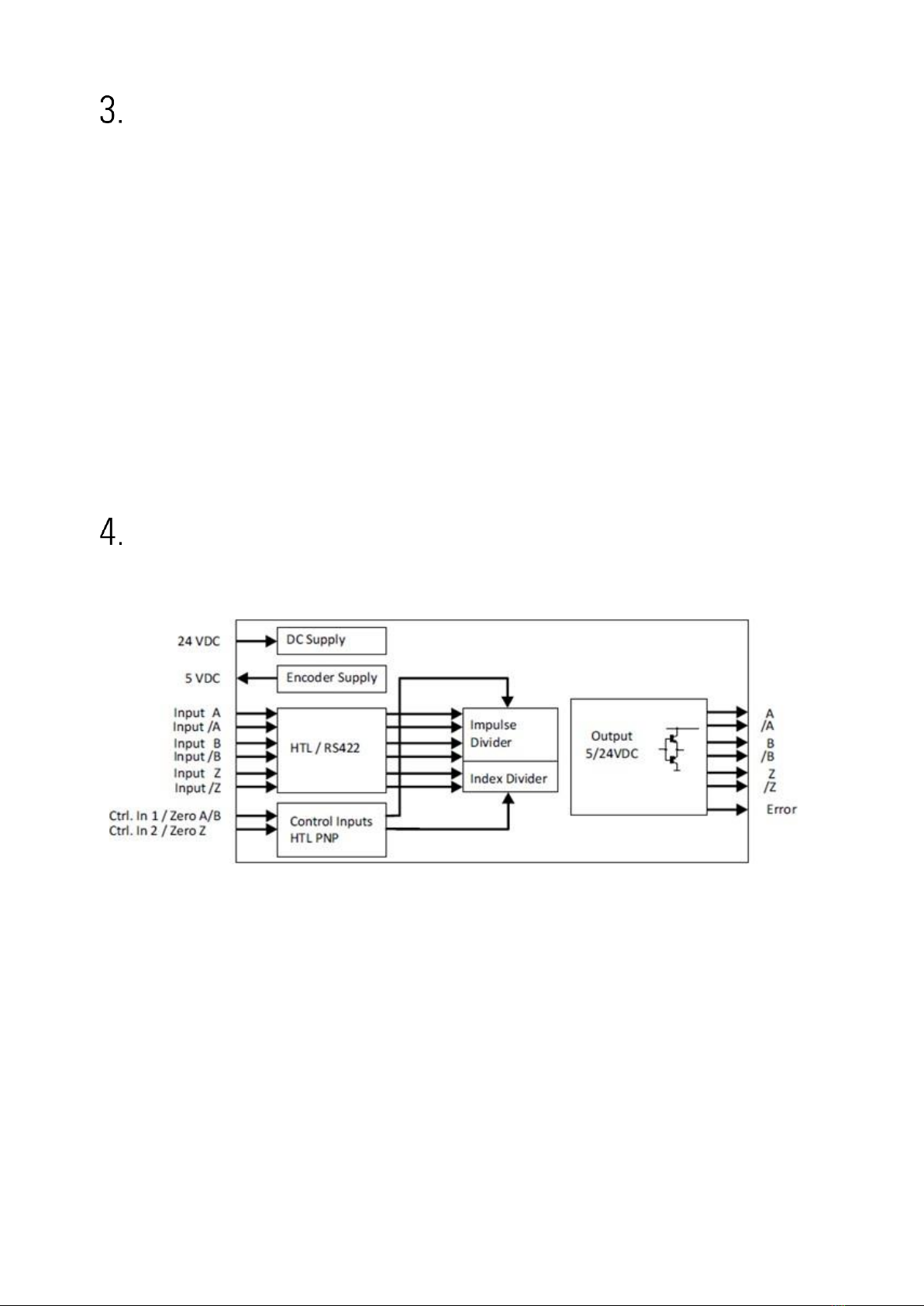

Block diagram ........................................................................7

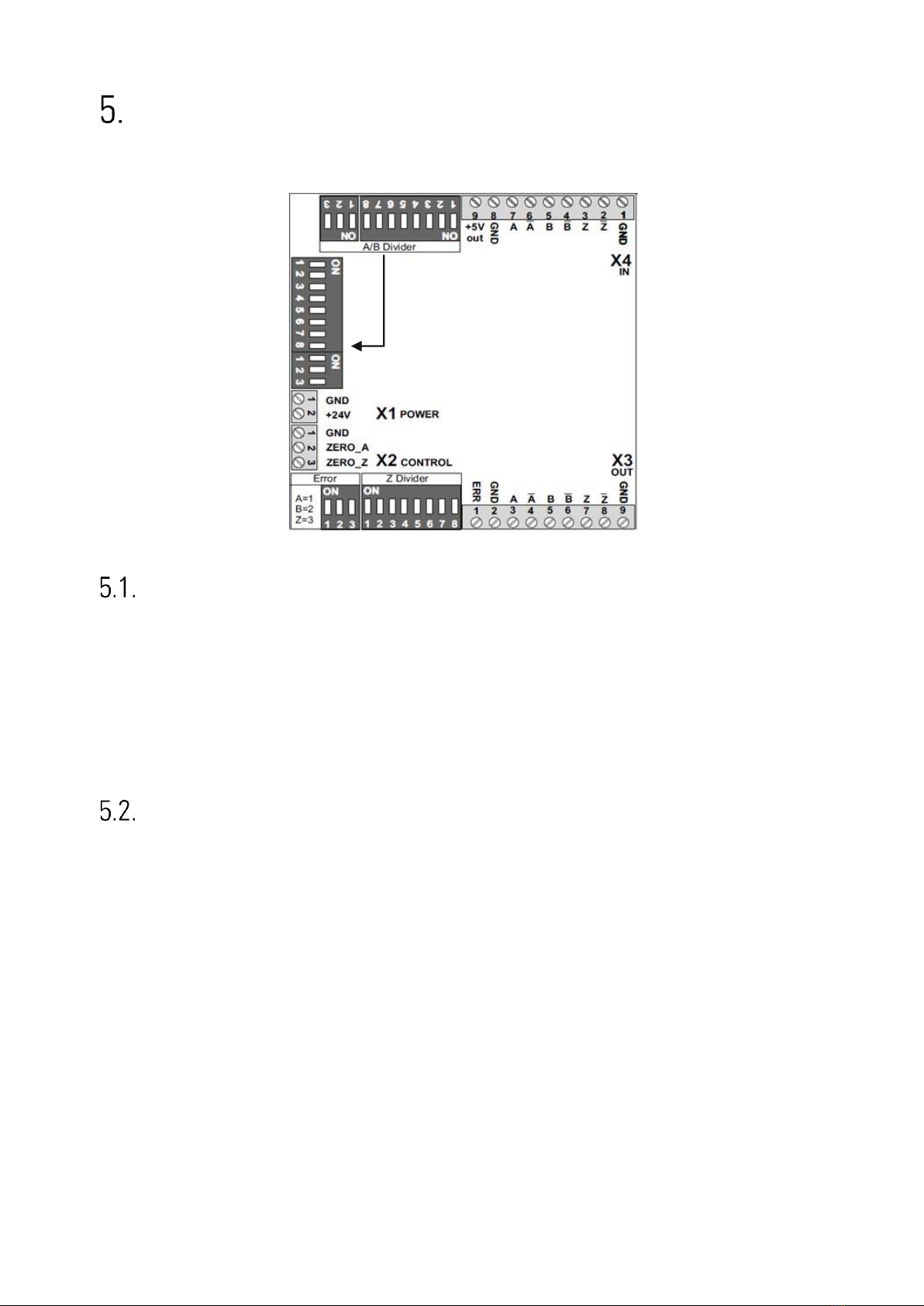

Electrical Connections .................................................................. 8

DC Power Supply .............................................................................. 8

Auxiliary Voltage Output .......................................................................... 8

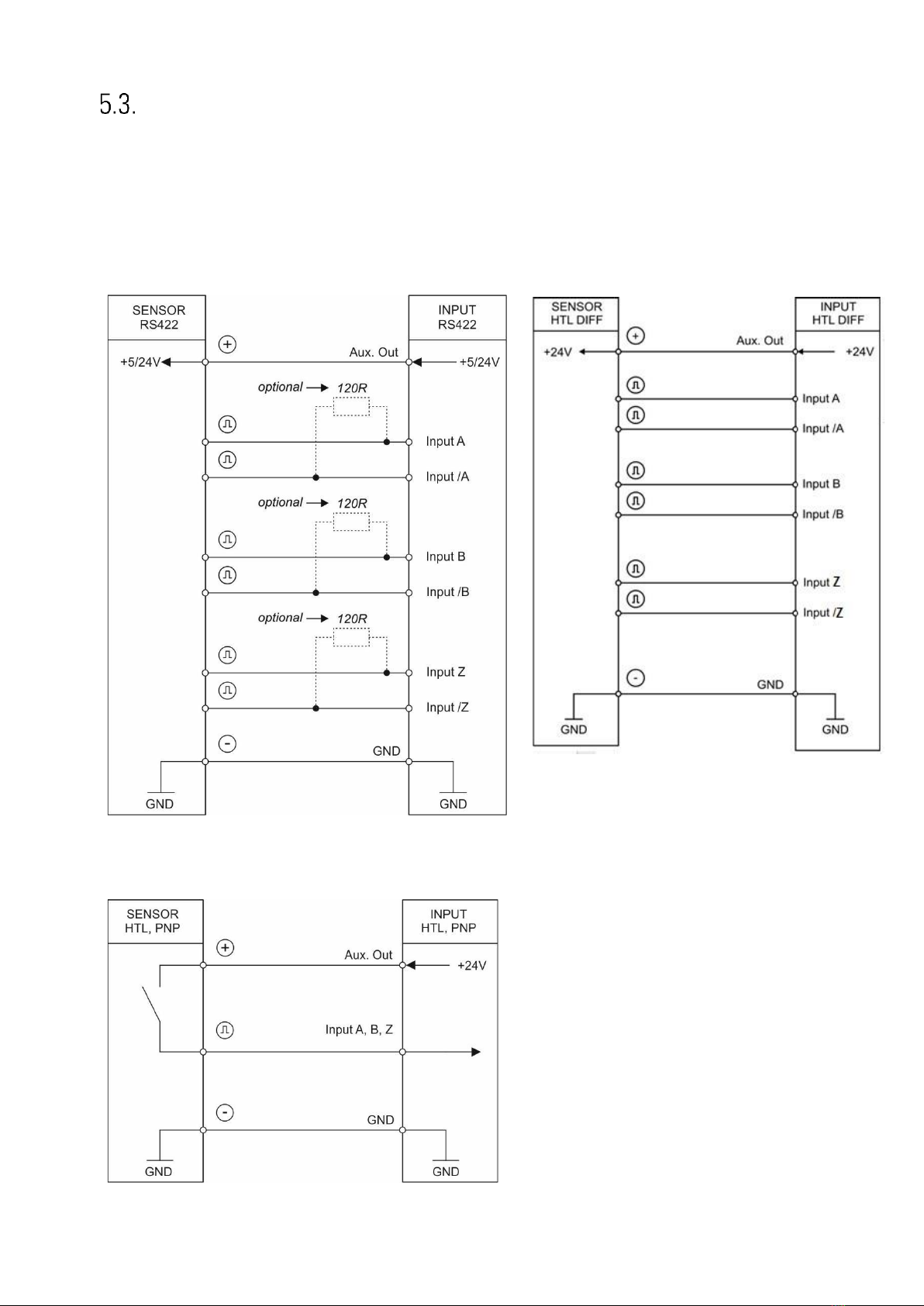

Incremental Inputs A, /A, B, /B, Z, /Z .......................................................... 9

Control Inputs ......................................................................................10

Pulse output ........................................................................................10

Error Ausgang.................................................................................11

LED .............................................................................................11

Input and output configuration ....................................................... 12

Level converter A/B Pulse (A/B Divider: All OFF).............................................13

Input/Output Mode Converter (A/B Divider: All OFF)........................................13

Adjustable divider A/B................................................................. 14

Setting the A/B Divider (at A/B Dir to A/B 90°) ...............................................14

Setting the A/B divider (for all other modes) .................................................15

Setting to zero the A/B divider with ZERO_A Signal..........................................17

Informationen over the signal change A/B Dir ................................................17

Adjustable divider Z .................................................................... 18

Pegel conversion Z Puls (Z Divider: all OFF) ...................................................18

Setting the Z Divider ..............................................................................18

Location and width of the Z pulse...............................................................19

Independent Z Divider ............................................................................20

Automatic generation of a Z pulse ..............................................................21

Reset the Z divider with ZERO_Z Signal ........................................................21

Dimensions.......................................................................... 22

Technical Specifications ............................................................... 23